Precision Metal Stamping

Custom Component Part

We provide comprehensive metal stamping services, from initial design to final delivery, including material selection, process optimization, rapid prototyping, and large-scale production. Our expertise includes Progressive stamping and deep drawing stamping processes, ensuring customized solutions with high quality and efficiency to meet your specific needs.

Your One-Stop Solution for Advanced Metal Stamping Services

At Plantmetal, a division of Lingshantech, we specialize in designing and manufacturing complex progressive dies, heavy-duty deep drawing processes, and high-precision metal stamping services. Equipped with 20 presses ranging from 25 to 300 tons, featuring servo feed and die protection control, we are capable of mass production across a wide range of materials.

As a leading OEM manufacturer, we support high-volume metal stamping for industries such as automotive, electronics, and consumer goods, producing components like electronic connectors, contacts, clips, and more. Our continuous investment in equipment enables us to meet the evolving demands of various industries, improving production efficiency, competitive pricing, and product quality.

We offer comprehensive services, including metal stamping, mechanical engineering, prototype design, injection molding, and manufacturing support. Our collaborative product development approach ensures we work closely with clients to meet their specifications, preparing design-for-manufacturing (DFM) solutions and ensuring timely delivery.

Featured Stamping Projects

WHAT WE OFFER

We are a trusted supplier specializing in the production of precision hardware components. Committed to consistently meeting your needs, we offer tailored solutions that align with industry-specific requirements. Our core services are designed to deliver superior performance, quality, and reliability.

Our facility features 25 punch presses, precision wire EDM machines, grinding equipment, welding and polishing tools, and ultrasonic cleaning systems. With advanced processing and testing capabilities, we deliver reliable, high-performance metal stamping solutions backed by stringent quality assurance.

- Custom Stamped Connectors

- Deep Drawing Sleeve

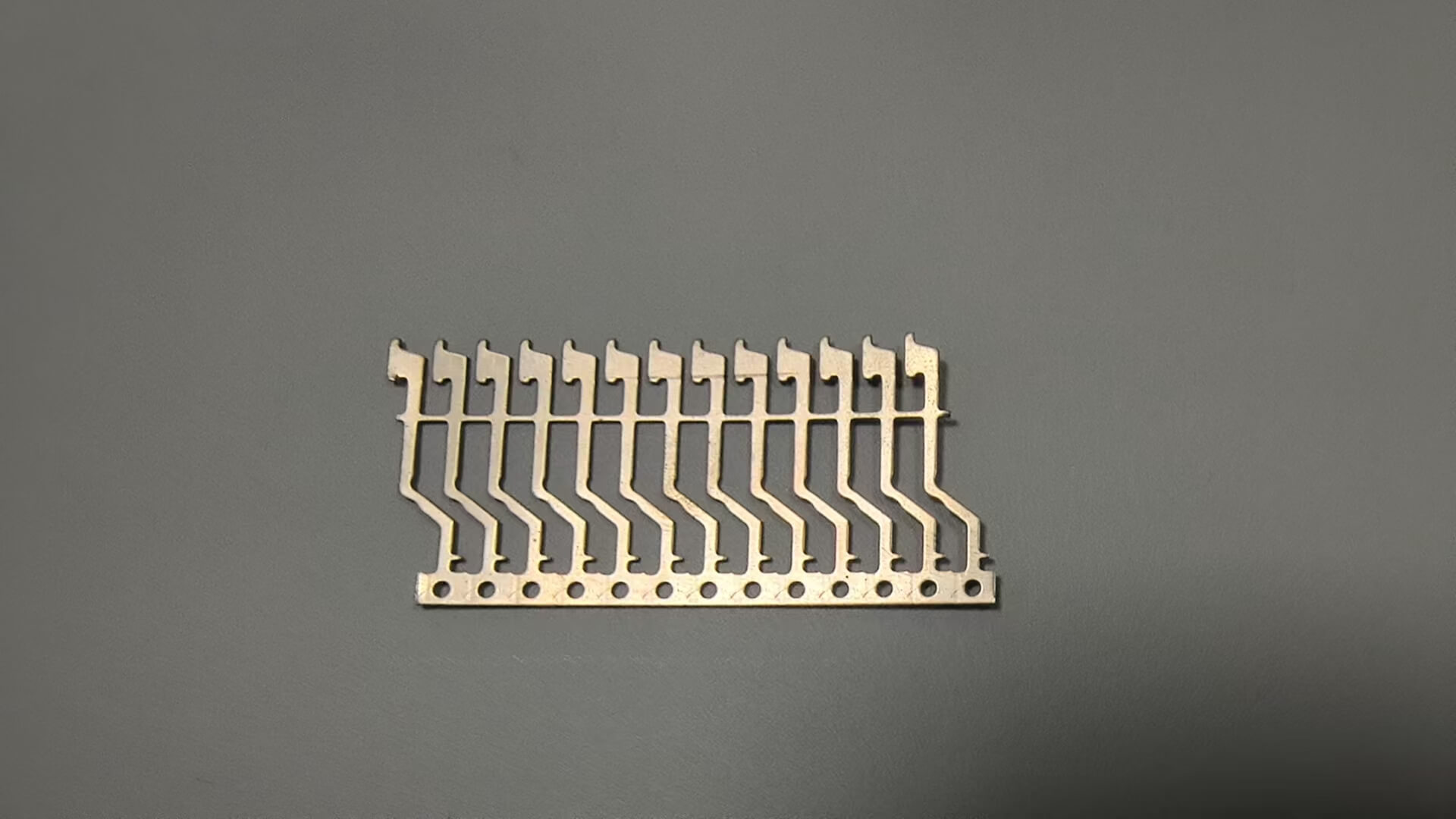

- Lead Frames

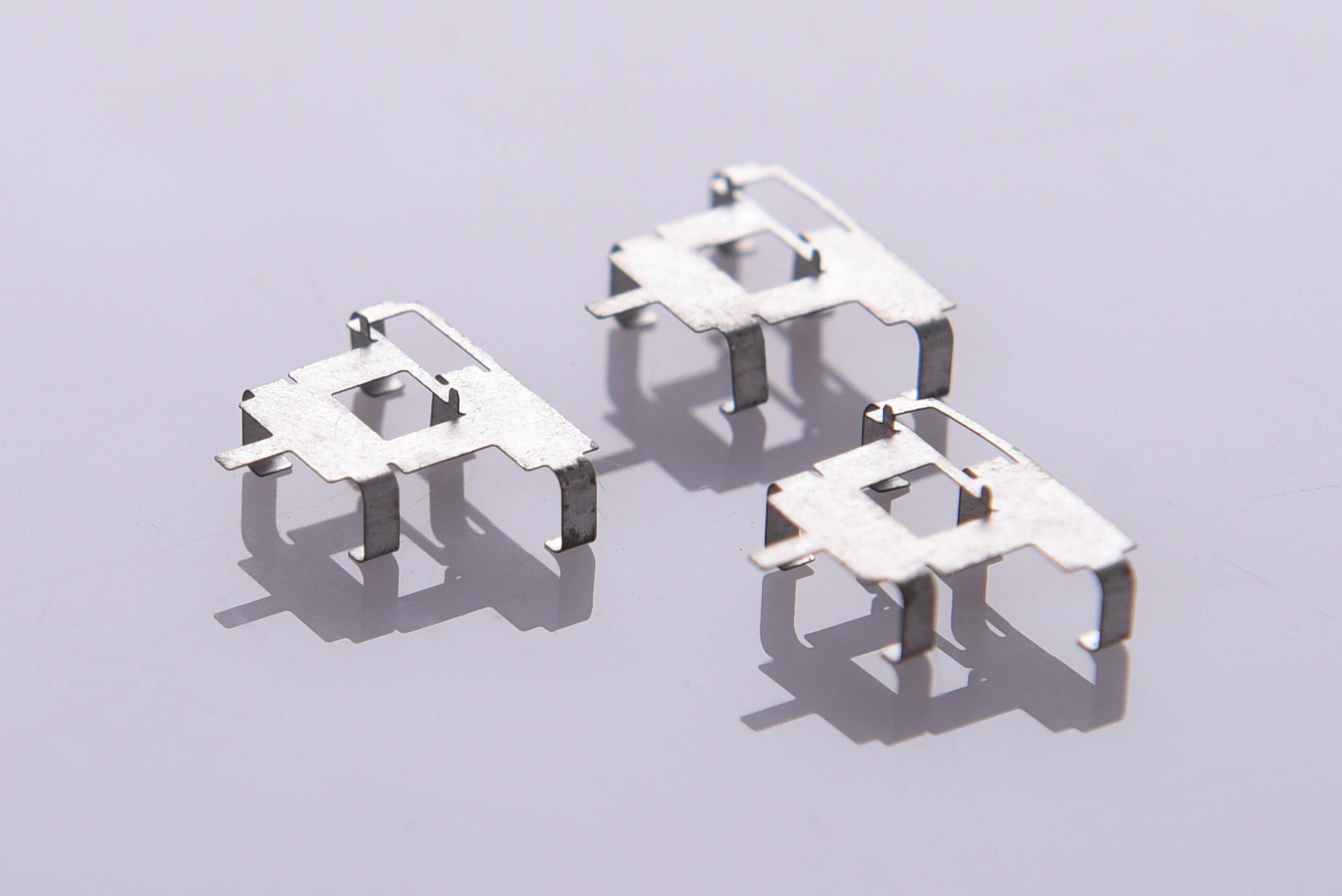

- Metal Clips

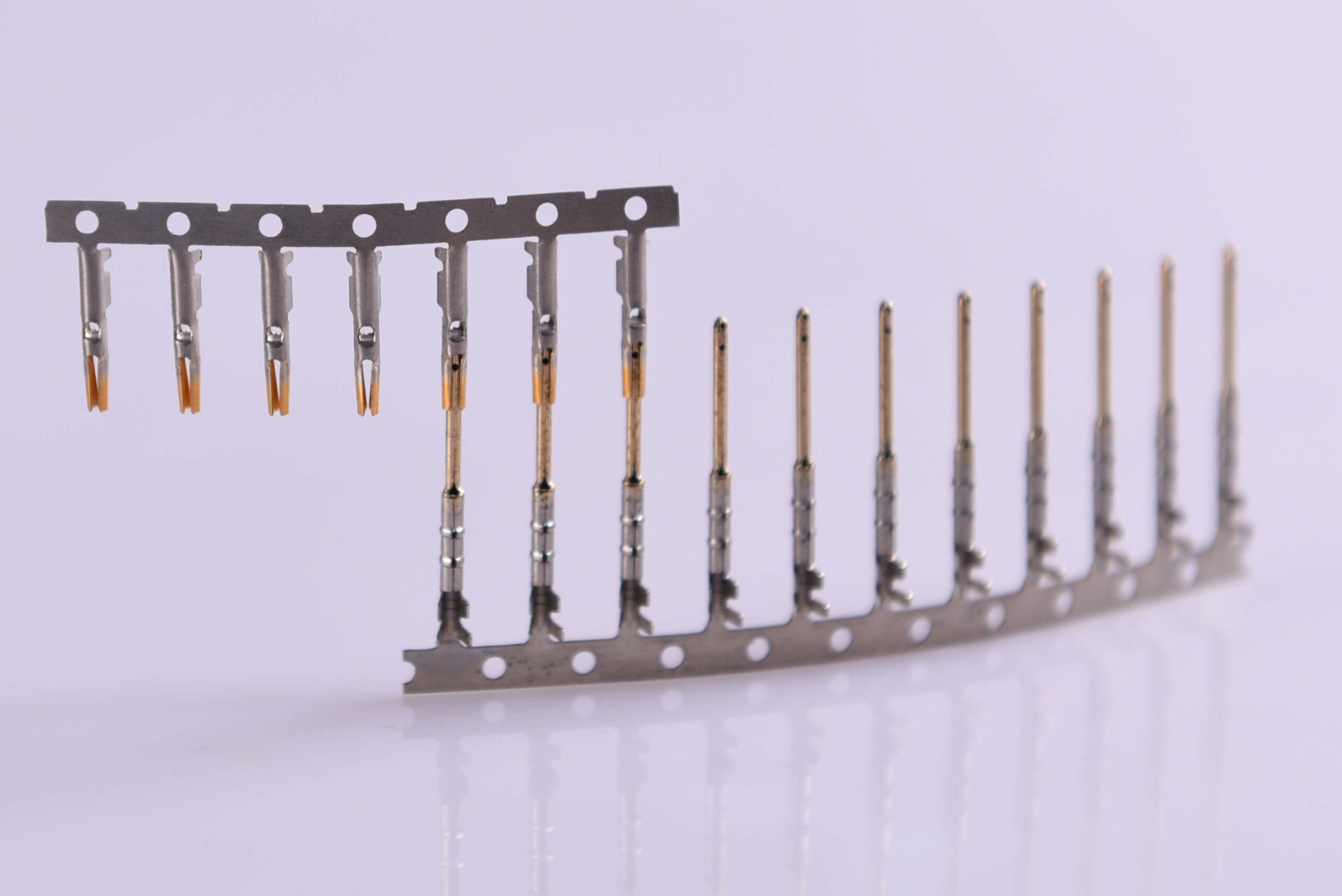

- Electronic Stamped Contacts

Custom Stamped Connectors

Material: Copper-5191

Post Process

Gold plating, silver plating, nickel-plating, tinplating

Applications of Custom stamped connectors

Aerospace Electronics: heavy duty aviation plug connector

New Energy: Heavy duty connector

Automotive: stamped connector

Deep Drawing Sleeve / Micro Deep Drawing Sensors Components

Material: Stainless steel 301/304, Aluminum-5052, Copper-1100,Copper-5191,Brass-6265,7275

Post Process

Stainless Steel: Passivation

Aluminum: Anodization

Copper: nickel plating, tinplating

Application Industry - Main industry sensor deep drawing parts

Lead Frames

Material: Copper-1100

Post Process

Copper: Passivation, Golden plating, silver plating, nickel plating, tinplating

Applications : Semiconductor and Electronics Industry,Automotive Electronics Industry,Telecommunications Industry,Consumer Electronics Industry,Industrial Control and Automation,Medical Equipment Industry

Car Air Control Button Shrapnel Metal Stamping Clips

Material: SUS301/631

Post Process

Copper: Passivation, Golden plating, silver plating, nickel plating, tinplating

Stainless Steel-Acid passivation, Temper to 250-280 ° C

Terminal Connectors

Material: Copper-1100,Copper-5191,Brass-6265,7275

Post Process

Copper: Golden plating, silver plating, nickel plating, tinplating

Working With Plantmetal

Why Choose Us?

State-of-the-Art Equipment and Technology

Our investment in cutting-edge metal stamping equipment and technology includes high-speed presses, multi-station dies, and automated production lines. Utilizing these advanced tools enables us to achieve higher production speeds and greater efficiency in metal stamping operations.

Multi-Station Stamping Technology

We leverage multi-station stamping technology, allowing multiple processes such as cutting, bending, forming, and piercing to be executed simultaneously on a single press. This technology enhances production efficiency and reduces component handling and movement, leading to lower production costs.

Quality Assurance and Certification

Our commitment to delivering high-quality metal stampings is evidenced by our ISO 9001 and IATF 16949 certifications. We enforce rigorous quality control measures throughout the production process, including material inspection, process control, and finished product testing, ensuring each product meets stringent customer and industry standards.

High Precision and Consistency

We meticulously control process parameters and quality requirements at each production step to guarantee the precision and consistency of every metal stamping. Utilizing advanced measurement equipment and quality control tools, we ensure each product adheres to the specified requirements.

Material Selection and Optimization

We collaborate with suppliers to choose high-quality metal materials and optimize them based on customer specifications. This strategic material selection and optimization enhance the strength, corrosion resistance, and wear resistance of our products, meeting diverse application needs.

Engineering Support and Collaboration

Our experienced engineering team works closely with customers, providing technical support and solutions. We offer expertise in product design, process optimization, and cost control, helping customers achieve the best possible metal stamping solutions.