In the rapidly evolving landscape of manufacturing, standardized solutions often fall short of addressing the distinct requirements of specialized applications. This is where custom metal clips prove invaluable, providing tailored solutions that ensure optimal performance, durability, and precision. At Plantmetal, we are committed to designing and producing high-volume custom metal clips tailored to a wide array of industries. Our offerings extend across sectors including automotive, aerospace, renewable energy, and medical devices, where our clips play a pivotal role in achieving reliable functionality in demanding conditions.

This article will explore the critical significance of custom metal clips, our advanced manufacturing processes, and the distinct advantages they confer to enhance your production efficiency.

Significance of Custom Metal Clips

Custom metal clips are meticulously designed to meet precise specifications concerning dimensions, material properties, and performance standards. In sectors that require high precision or operate in extreme environments—such as aerospace, military, construction, and telecommunications—the selection of the appropriate clip is essential for ensuring product reliability and operational safety.

At Plantmetal, our skilled engineers and manufacturing specialists recognize the specific challenges that our clients face. We collaborate closely with them to develop custom metal clips that not only fulfill their requirements but also surpass their expectations, contributing to their overall success.

Advanced Manufacturing Techniques

To accommodate the diverse needs of our clients, Plantmetal utilizes cutting-edge manufacturing technology. Our Four-Slide and Multi-Slide metal forming machines, combined with mechanical punch presses, enable us to produce a wide variety of wire clip configurations with unparalleled precision and repeatability. This flexibility allows us to manufacture both straightforward and highly intricate designs with exceptional accuracy.

Our manufacturing process goes beyond just stamping; we also offer a suite of secondary services that elevate the quality and functionality of each clip, including:

– Deburring: Ensuring smooth edges for safe and efficient usage.

– Austempering: Enhancing the toughness and strength of clips.

– Plating: Applying protective or decorative layers to improve corrosion resistance.

– Dip Spin Coatings: Providing uniform coatings that enhance durability and aesthetics.

Tailored Clip Designs for Diverse Applications

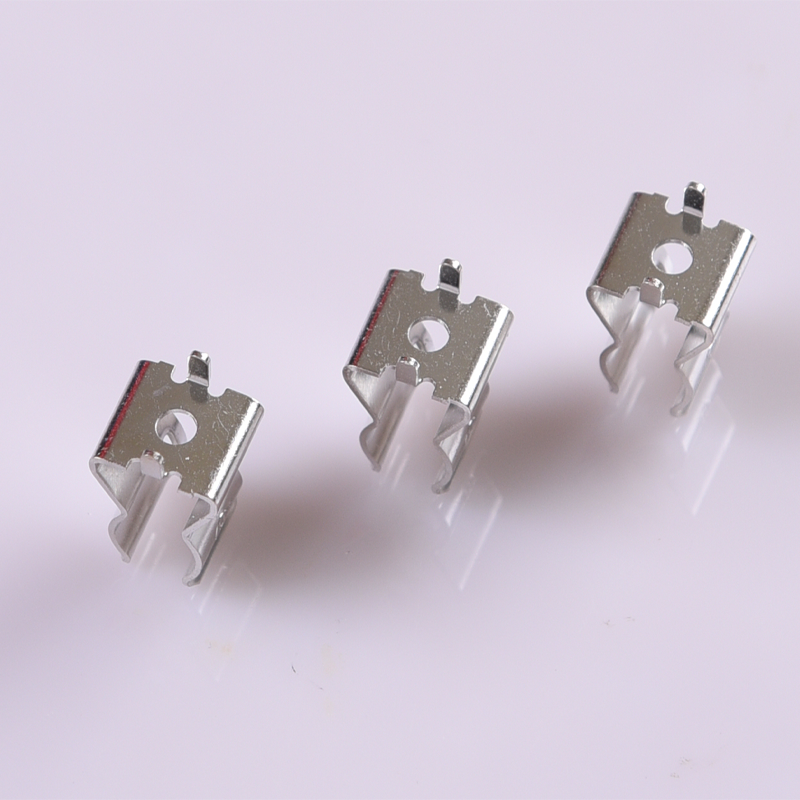

Our proficiency extends well beyond standard wire clip designs. With an extensive portfolio of over 300 different custom clips produced in our advanced production facilities, we can accommodate nearly any design requirement. Some of the prominent custom designs we manufacture include:

– U-Clips: Commonly used in automotive and construction sectors.

– C-Clips: Ideal for securing panels and flat surfaces.

– S-Clips: Designed for attaching multiple components.

– D-Spring Clips: Suited for applications demanding high flexibility and strength.

– Solar Panel Wire Management Clips: Essential for organizing solar energy installations.

– Flat Spring Clips: Perfect for providing secure tension in various applications.

– Dart Clips, Terminal Clips, and Tubular Clips: Tailored to meet the unique needs of specific industries.

– Metal Hinge Clips: Ensuring reliable support for hinged components.

– Industrial Metal Shelf Clips: Widely used in shelving solutions for adjustable and robust support.

Our ability to fabricate complex custom metal clips is further augmented by our expertise in CAD/CAM, CNC machining, and EDM technologies, enabling rapid prototyping and efficient full-scale production runs. We transform even the most intricate designs into high-performance clips that seamlessly integrate into your manufacturing workflow.

Strategic Material Selection for Enhanced Performance

Choosing the right material is critical in designing custom metal clips, as it directly influences the clip’s strength, durability, and resistance to environmental factors. At Plantmetal, we provide a comprehensive selection of materials to ensure that your clips are ideally suited for their intended applications. Some of the frequently utilized materials include:

– Stainless Steel: Renowned for its strength and resistance to corrosion, making it suitable for harsh environments.

– Aluminum: Lightweight and durable, ideal for industries where weight reduction is crucial.

– Phosphor Bronze: Provides excellent electrical conductivity and corrosion resistance.

– Beryllium Copper: A non-magnetic, corrosion-resistant material with superior electrical conductivity.

– Low Carbon and High Carbon Steel: Offered in various grades to meet different strength requirements.

– Nickel: Known for its exceptional corrosion resistance, perfect for highly corrosive environments.

– Brass: A versatile option recognized for its machinability and corrosion resistance.

Enhanced Durability through Superior Surface Treatments

To maximize the performance and longevity of our metal clips, we provide a variety of advanced surface treatments, including:

– Galvanization: Protects clips from corrosion, making them suitable for outdoor and corrosive applications.

– Powder Coating: Applies a resilient, protective finish that resists chipping and wear.

– Anodizing: Delivers a decorative and corrosion-resistant finish, particularly popular for aluminum clips.

These treatments not only improve the functionality of our clips but also ensure they retain their appearance and effectiveness over time.

Commitment to Quality Assurance

At Plantmetal, our commitment extends beyond mere manufacturing; we strive to ensure that each clip meets the highest standards of quality and precision. Our certifications, including ISO 9001, ISO 14001, and IATF 16949, underscore our dedication to excellence. Our quality management system incorporates advanced technologies, including inline and offline camera vision systems and sensor technology tailored to each production line.

Our state-of-the-art quality laboratory rigorously tests and inspects every batch of clips before they are dispatched from our facility. Whether you require a prototype or a large-scale production run, we guarantee that your custom metal clips will adhere to your precise specifications.

Why Choose Plantmetal?

When it comes to sourcing custom metal clips, Plantmetal stands out for several compelling reasons:

- Expertise: With over sixty years of experience, we are recognized leaders in metal stamping and fabrication.

- Advanced Facilities: Our production environment is equipped with the latest manufacturing technologies, ensuring high precision and efficiency for every project.

- Customization: We collaborate closely with clients to develop tailored solutions that meet their specific needs.

- Quality Assurance: Our stringent quality control measures guarantee that every clip meets the highest standards.

- Cost-Effectiveness: We deliver high-quality products at competitive prices, ensuring timely delivery to align with your production schedules.

Since our inception in 1998, Plantmetal has been at the forefront of precision metal engineering, serving clients across various industries worldwide. Whether you require a bespoke metal clip for a niche project or high-volume production, we possess the experience, technology, and commitment to deliver exceptional results.

If you are interested in discovering how Plantmetal can provide the ideal custom metal clip solution for your business needs, please reach out to us today or request a quote. Our experienced team is poised to assist you in enhancing your manufacturing processes.

In summary, this post has detailed the numerous advantages of custom metal clips and the compelling reasons why Plantmetal is your ideal partner for metal stamping solutions. Our advanced manufacturing capabilities, premium materials, rigorous quality control, and competitive pricing create a comprehensive solution for industries demanding precision and reliability. Opt for customized solutions over generic alternatives and collaborate with Plantmetal for all your custom metal clip requirements!