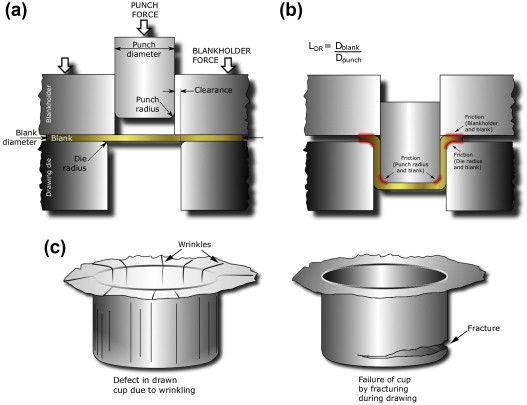

Aluminum deep drawing is a metal forming process used to manufacture precise and durable components by pulling a flat aluminum sheet into a die to create complex, deep shapes. This technique is ideal for producing lightweight, corrosion-resistant parts with excellent strength-to-weight ratios, making it popular in industries such as automotive, aerospace, and consumer electronics. Aluminum’s high malleability allows for intricate shapes while maintaining its structural integrity. The deep drawing process provides smooth, seamless finishes and reduces material waste, offering an efficient solution for high-volume production of custom aluminum parts.

Advantages to Drawing Aluminum

Aluminum has many advantages, including:

- It is about one-third the weight of steel, which makes it an ideal candidate for aerospace products that require certain strength-to-weight ratios.

- It has good dent resistance for outer body automotive panels.

- It is fully recyclable.

- It is rust-proof (brown rust).

Disadvantages to Drawing Aluminum

Aluminum is:

- Far more expensive that steel.

- Limited to certain geometric features using economical processes.

- Abrasive to tooling (aluminum oxide is very abrasive).

- Difficult to weld.

- Prone to severe springback.

Surface Treatment Options:

1.Anodization

Enhances aluminum’s natural oxide layer for improved corrosion resistance and wear properties, available in various colors.

2.Powder Coating

Durable finish resistant to chips, scratches, and fading, offering extensive color and texture choices.

3.Electroplating

Deposits metal layers like nickel, zinc, or chrome to enhance appearance, corrosion resistance, and surface hardness.

4.Passivation

Chemical treatment to boost corrosion resistance without altering appearance.

5.Polishing

Creates a smooth, reflective surface for improved aesthetics.

6.Brushing

Uniform satin texture that hides fingerprints and minor scratches.

7.Painting

Customizable colors and protective coating.

8.Sandblasting

Creates a textured finish for enhanced adhesion and unique appearance.

Our Advantages:

Optimal Material Selection:

We select premium raw materials known for their durability, high hardness, and resistance to rust and deformation over extended periods, ensuring your purchase is reliable and long-lasting.

Advanced Surface Treatment:

Our surface treatments are designed for superior performance, delivering a light, attractive exterior with a comfortable tactile feel.

Stringent Quality Control:

Our rigorous quality control measures include standardized testing equipment and strict product inspections to ensure optimal product protection.

Tailored Customization Services:

We offer diverse specifications with ample inventory to accommodate customized processing according to customer requirements, ensuring competitive pricing.