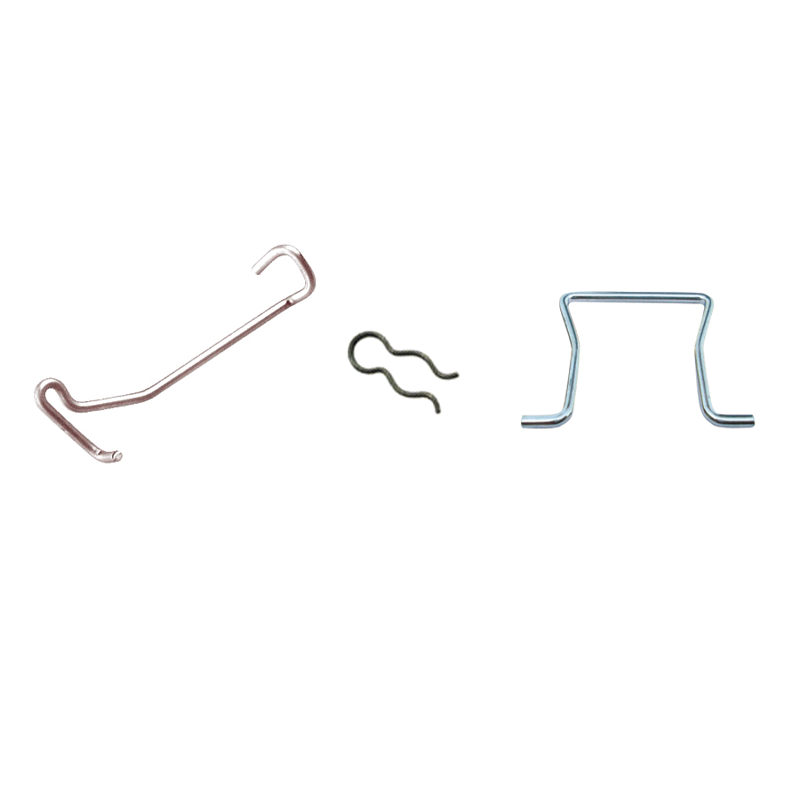

Wire forms are versatile components made by bending and shaping metal wire into various configurations, commonly used in industries such as automotive, electronics, medical, and aerospace. These forms can be produced from a range of materials, including steel, stainless steel, brass, and aluminum, and are designed to meet specific functional needs, such as springs, clips, hooks, and brackets. Using precision techniques like CNC bending, cutting, and coiling, wire forms are tailored to exact specifications, ensuring strength, flexibility, and durability. Customization options include different shapes, sizes, and finishes, making wire forms adaptable for diverse applications.

Basic Information

– Surface Treatment: Electroplating

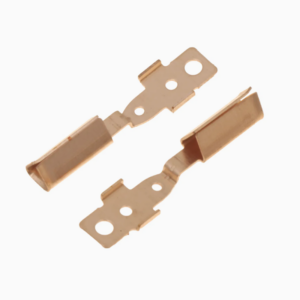

– Forming Process: Metal Stamping Parts

– Surface Finish Options: Nickel Plating, Sn Plating, Tin Plating, Zinc Plating

– Sample Availability: Available

– Tolerance: ±0.001 mm

– Size: Customizable as per requirement

– Application: Industrial, Furniture, Automotive, Motorcycle, etc.

– Manufacturing Approach: Metal Stamping, Cutting, Punching, Bending, Welding

– Transport Packaging: OPP Bag, Box, or Custom

– Specification: Customized

– Origin: Xiamen, China

The Production Process for Our Metal Stamping Parts:

- Order Receipt and Drawing Review

– Receive and review customer orders, including technical drawings in formats such as DXF, IGS, STEP, or PDF.

- Design Confirmation

– Confirm design details with the customer to ensure accuracy before production begins.

- Material Preparation

– Select and prepare metal sheets according to the required specifications.

- Precision Cutting

– Utilize laser cutting and CNC shearing to cut metal sheets to precise dimensions.

- Forming and Shaping

– Perform bending, punching, and stamping to achieve the desired shapes and features.

- Welding and Riveting

– Join metal components using advanced welding techniques and riveting.

- Surface Treatment

– Apply necessary surface treatments, including plating and spraying, to enhance durability and appearance.

- Assembly and Quality Control

– Assemble the components and conduct rigorous quality checks to ensure adherence to specifications.

- Packaging and Shipping

– Package finished parts securely and manage logistics for timely delivery to the customer.

- After-Sales Support

– Provide ongoing support and address any post-delivery issues to ensure customer satisfaction.