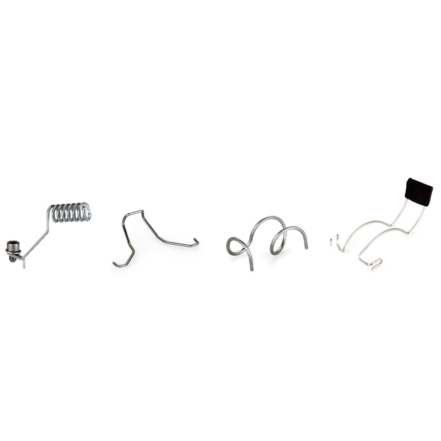

Precision wire forms are custom-shaped metal components created from high-quality wire, used across various industries for their strength, flexibility, and exactness. Made from materials like stainless steel, carbon steel, or aluminum, these wire forms are crafted to precise specifications through specialized processes such as bending, cutting, coiling, and welding. Industries such as automotive, aerospace, medical, and electronics rely on precision wire forms for applications that require intricate shapes, including springs, clips, hooks, and frames.

The precision manufacturing process ensures that each wire form meets strict tolerances for both functionality and durability, making them essential for assemblies that demand reliable, high-performance parts. In addition to their practical applications, precision wire forms are customizable in size, shape, and finish, allowing for tailored solutions that meet the unique needs of each application.

Basic Information

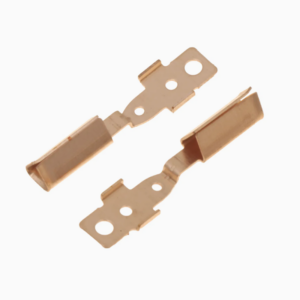

– Surface Treatment: Electroplating

– Forming Process: Metal Stamping Parts

– Surface Finish Options: Nickel Plating, Sn Plating, Tin Plating, Zinc Plating

– Sample Availability: Available

– Tolerance: ±0.001 mm

– Size: Customizable as per requirement

– Application: Industrial, Furniture, Automotive, Motorcycle, etc.

– Manufacturing Approach: Metal Stamping, Cutting, Punching, Bending, Welding

– Transport Packaging: OPP Bag, Box, or Custom

– Specification: Customized

– Origin: Xiamen, China

Customization Services for Metal Stamping Parts

– Design and Engineering: We offer comprehensive design and engineering services to tailor metal stamping parts to your specific requirements. Our team utilizes advanced CAD software and technical expertise to develop precise designs that meet your operational needs.

– Material Selection: Choose from a wide range of high-quality metals and alloys suitable for various applications. We ensure that the materials used align with your performance and durability requirements.

– Prototyping: We provide prototyping services to validate designs and functionality before full-scale production. This step ensures that the final product meets all specifications and quality standards.

– Tooling and Die Creation: Our precision tooling and die creation process ensures accurate and consistent part production. We use advanced machinery to fabricate tools that enhance production efficiency.

– Production: Utilizing state-of-the-art metal stamping technology, we produce parts with high precision and consistency. Our facilities are equipped to handle both small and large production runs.

– Quality Control: Each part undergoes rigorous quality control checks to ensure it meets the highest standards. We perform dimensional inspections, functionality tests, and material evaluations to guarantee reliability.

– Finishing and Surface Treatment: We offer a range of finishing options, including electroplating and polishing, to enhance the appearance and performance of your parts.

– Packaging and Delivery: Customized packaging solutions ensure that your parts are securely transported and delivered on time. We coordinate logistics to meet your scheduling needs.

– After-Sales Support: Our commitment extends beyond delivery. We provide ongoing support to address any issues and ensure customer satisfaction with our products.