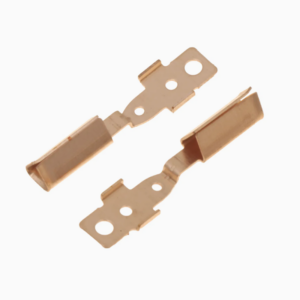

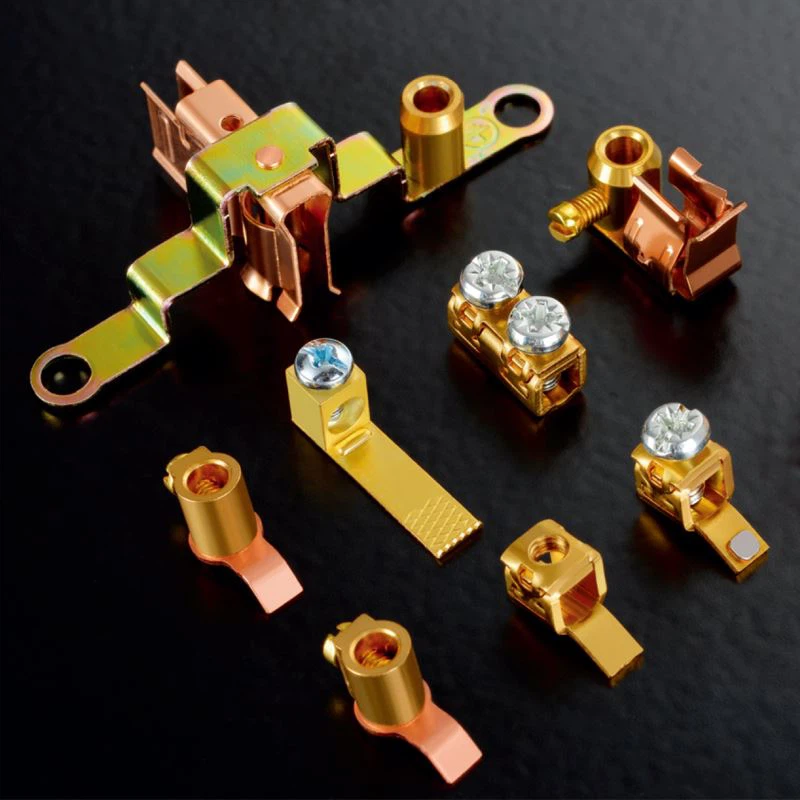

Overview:

Our silver electrical contact products are meticulously engineered and produced to meet the highest standards of quality and dependability. Leveraging advanced in-die welding technology, we ensure exceptional product consistency and stability throughout the production process.These Silver metal electrical contacts not only deliver outstanding performance but also offer a significant cost advantage. By utilizing in-die welding technology, we are able to streamline production, enabling high-volume manufacturing that reduces costs and enhances overall production efficiency.

Details:

| Specification | Details |

| Craftsmanship | Stamping, CNC |

| Finish | Plating (Electroplating, Nickel Plating, etc.) |

| Price | Real-time Factory Pricing |

| Packing | Inner: Plastic bag and PE Foam; Outer: Carton packaging |

| Services | OEM services available for custom designs and specifications |

| Place of Origin | Xiamen, China |

| Material Options | Aluminum, Stainless Steel, Brass, Copper, Plastic, etc. |

| Color Options | White, Black, Red, Blue, Silver, Gold, Custom colors available |

| Certifications | ISO9001:2015, SGS Certified |

| Production Capacity | 5,000 units per day (per machine) |

| Lead Time | 7–15 days depending on order size and complexity |

| Testing | 100% inspection, Third-party inspection upon request |

| Shipping Options | DHL, FedEx, UPS, TNT, EMS, by sea, by truck, or by train |

Production Process:

- Material Selection: High-purity silver and other alloy materials are carefully selected to ensure excellent electrical conductivity, durability, and corrosion resistance.

- Die Design and Tooling: Precision die designs are created using advanced CAD/CAM software to ensure optimal shaping of the electrical contact components. The dies are then manufactured with high precision using CNC machining or other advanced techniques.

- Stamping and Shaping: The raw materials are stamped using high-precision stamping machines, forming the basic shape of the electrical contacts. This process is carefully monitored to maintain consistent dimensions and quality.

- In-Die Welding: For certain designs, in-die welding technology is used to join components during the stamping process. This ensures strong, seamless connections and eliminates the need for additional assembly steps.

- Surface Treatment: The electrical contacts undergo various surface treatments such as plating, polishing, or coating to enhance their durability, electrical conductivity, and resistance to wear and corrosion.

- Inspection and Testing: Every batch of silver metal electrical contacts undergoes rigorous testing, including dimensional checks, visual inspections, and electrical performance testing to ensure conformity to specifications and industry standards.

- Packaging: Once approved, the electrical contacts are carefully packaged to prevent damage during shipping, ensuring they arrive in optimal condition.

- Shipping: The final product is then shipped to customers, with options for expedited or standard shipping depending on the customer’s requirements.

Surface Treatment Options:

– Anodizing: Provides a durable, corrosion-resistant finish with enhanced surface hardness, ideal for aluminum components.

– Powder Coating: Delivers a tough, high-quality finish that resists chipping, scratching, and fading, available in a wide range of colors.

– Painting: Offers a smooth, aesthetically pleasing finish with excellent adhesion, ideal for both protective and decorative applications.

– Sandblasting: Produces a uniform, matte texture on metal surfaces, enhancing their appearance and preparing them for further finishing treatments.

– Polishing: Achieves a high-gloss, mirror-like finish that improves the visual appeal of the surface while providing a smooth, refined texture.

Factory Show: