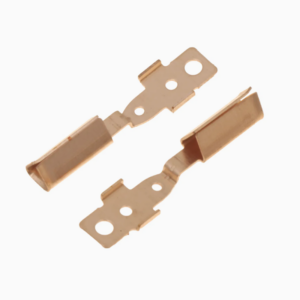

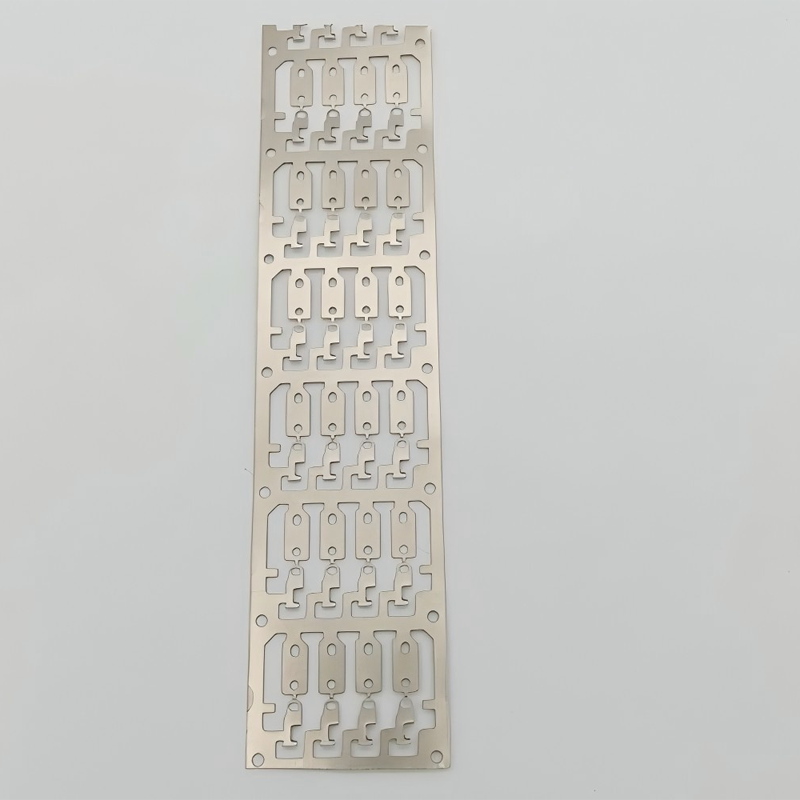

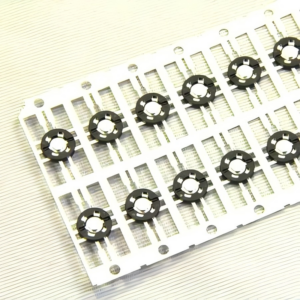

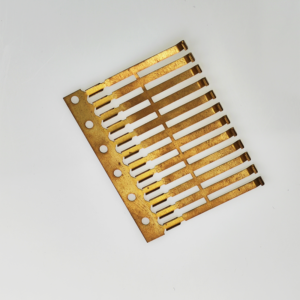

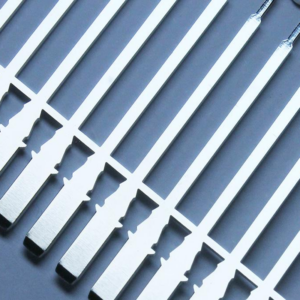

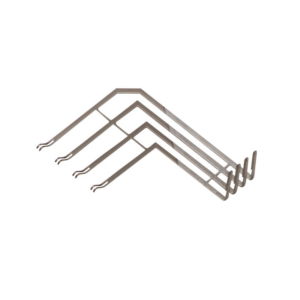

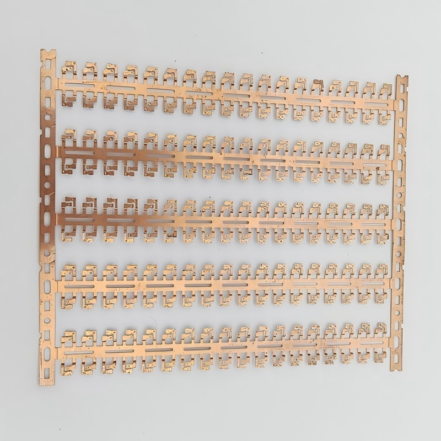

Progressive stamping lead frames are precision-engineered components used in the semiconductor and electronics industries, particularly for packaging integrated circuits (ICs) and LEDs. The progressive stamping process involves feeding a metal strip through a series of stamping dies, where each stage of the process shapes, cuts, and forms the lead frame in incremental steps. This technique allows for high-volume production with minimal material waste and high consistency. Progressive stamping lead frames are designed to provide strong electrical connections, mechanical support, and efficient heat dissipation for the microchips they encapsulate. This method is ideal for producing complex, intricate lead frame designs required in modern electronic devices, ensuring both cost-effectiveness and precision in large-scale manufacturing.

Basic Information

– Surface Treatment: Electroplating

– Forming Process: Metal Stamping Parts

– Surface Finish Options: Nickel Plating, Sn Plating, Tin Plating, Zinc Plating

– Sample Availability: Available

– Tolerance: ±0.001 mm

– Size: Customizable as per requirement

– Application: Industrial, Furniture, Automotive, Motorcycle, etc.

– Manufacturing Approach: Metal Stamping, Cutting, Punching, Bending, Welding

– Transport Packaging: OPP Bag, Box, or Custom

– Specification: Customized

– Origin: Xiamen, China

One-Stop Service for Metal Stamping Parts

– Design and Prototyping: We provide end-to-end design services, including CAD modeling and prototyping, to ensure your metal stamping parts meet precise specifications and functionality requirements.

– Tooling and Die Development: Our facilities handle the complete tooling and die creation process, utilizing advanced technology to produce high-precision tools and dies that ensure consistent part quality.

– Metal Stamping Production: We offer comprehensive metal stamping services, capable of handling a wide range of materials and sizes. Our equipment supports both high-volume production and custom orders with exceptional accuracy.

– Surface Treatment: Enhance the performance and appearance of your parts with our surface treatment options, such as electroplating, coating, and polishing, tailored to meet your specific requirements.

– Quality Control: Our rigorous quality control process includes thorough inspections and testing to ensure that every part adheres to the highest standards of precision and durability.

– Custom Packaging and Logistics: We provide custom packaging solutions and manage logistics to deliver your stamped parts safely and efficiently, ensuring they arrive on time and in optimal condition.

– Post-Production Support: Our service extends beyond manufacturing, offering ongoing support to address any issues, provide maintenance, and ensure that your needs are continuously met.

Advantages of Our Product

Lighter weight

Lower cost

Higher load-carrying capacities

More resistant to shock loads and oscillations

More tolerant of shaft misalignments