Overview:

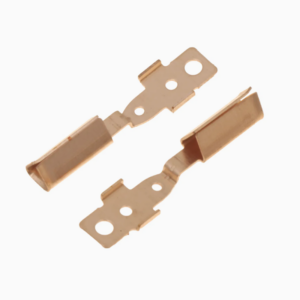

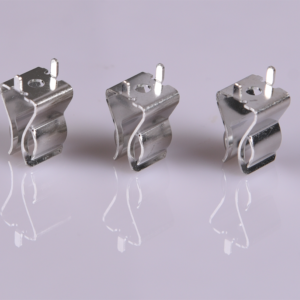

Stamped metal clips are precision-engineered fastening components widely used in industries such as automotive, electronics, and aerospace. These clips are manufactured through advanced stamping processes, including cutting, forming, and bending, to achieve accurate dimensions and consistent quality. Typically made from materials like stainless steel, carbon steel, aluminum, brass, and copper alloys, stamped metal clips offer durability, strength, and resistance to wear and corrosion. At our factory, we provide OEM services, allowing customization of metal clips in various sizes, shapes, and finishes to meet specific client requirements. Partner with us for high-quality, tailor-made solutions designed to enhance your applications.

Details:

| Category | Details |

| Processing Type | Shaping Metal |

| Material | Carbon Steel |

| Mold | Multistep Progressive Dies |

| Process | Forming Process |

| Industry | Metal Stamping Parts |

| Tolerances | 0.1mm |

| Material Type | Aluminum, Brass, Stainless Steel, Copper Sheet |

| Place of Origin | Xiamen, China |

| Technics | Stamping, Punching, Grinding |

| R&D Service | Design and Drawing |

| Dimension | Customized |

| Delivery Time | 30 Days After Payment |

| OEM Sample | About 10 Days |

| MOQ | Small Orders Accepted |

| Package | Custom Packaging |

| Trademark | OEM |

| Production Capacity | 50,000 PCS/Month |

Production Process of Stamped Metal Clips

-

Material Selection

Choose the appropriate material, such as stainless steel, carbon steel, brass, or aluminum, based on the clip’s application requirements.

-

Tooling and Die Preparation

Design and manufacture multistep progressive dies to ensure precise shaping and forming during production.

-

Cutting and Blanking

Cut raw metal sheets into predefined shapes and sizes using high-precision machinery.

-

Forming and Shaping

Perform bending, stamping, and forming operations to achieve the desired clip structure, ensuring uniformity and accuracy.

-

Secondary Processes

Apply additional steps like punching, grinding, or tapping to refine features and enhance functionality.

-

Surface Treatment

Enhance the clips’ durability and appearance with treatments such as plating, polishing, or anodizing.

-

Quality Inspection

Conduct rigorous testing to ensure dimensional accuracy, strength, and compliance with industry standards.

-

Customization and Assembly

Incorporate client-specific requirements, including custom dimensions, shapes, or finishes, followed by final assembly if needed.

-

Packaging and Delivery

Pack the clips according to client specifications and prepare for shipment within the agreed timeline.

Surface Treatment for Stamped Metal Clips

-

Plating

Apply protective layers such as zinc, nickel, chrome, or tin to enhance corrosion resistance, durability, and appearance.

-

Anodizing

Use this electrochemical process to create a robust oxide layer on aluminum clips, improving wear resistance and aesthetic appeal.

-

Powder Coating

Apply a durable and uniform coating for added protection against environmental factors while achieving a smooth, polished finish.

-

Polishing and Passivation

Refine the clip surface through polishing for enhanced smoothness and luster, and apply passivation to increase resistance to oxidation and corrosion.

Our Factory:

We operate a comprehensive range of plants and equipment to ensure the highest quality production. Our facilities are equipped with 25 punch presses ranging from 25 tons to 300 tons, precision wire EDM machines, grinding equipment, welding and polishing tools, and ultrasonic cleaning systems.

In addition to our manufacturing capabilities, we offer a variety of metal plating processes to enhance the durability, appearance, and functionality of our metal stamping products. These include electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our state-of-the-art plating facilities ensure consistent finishes, corrosion resistance, and compliance with industry standards.

This combination of professional and automated production lines, advanced mechanical equipment, rigorous quality control measures, and high-quality plating processes ensures we deliver metal stamping products of the highest standard.