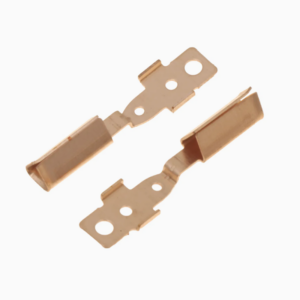

Description:

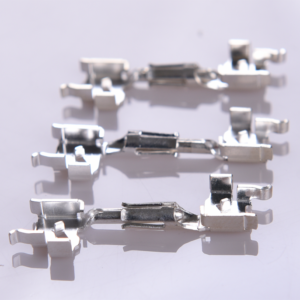

The copper female metal connector is a critical component in the new energy industry, designed to provide reliable electrical conductivity and durability in demanding applications such as electric vehicles, renewable energy systems, and energy storage solutions. Its advantages include superior corrosion resistance, excellent thermal conductivity, and robust mechanical performance, making it an ideal choice for high-performance and long-lasting connections in these innovative technologies.

We offer fully customizable services to meet your unique requirements, including size, dimensions, and material specifications. Partner with us to design and manufacture connectors tailored to your project needs. Contact us today to discuss your custom solutions and take advantage of our expertise in precision connector manufacturing.

Characteristics:

| Category | Details |

| Application | New Energy |

| Production Process | Progressive Stamping |

| Shape | Custom |

| Certification | IATF 16949, ISO 9001:2015 |

| Brand | OEM |

| Color | Gold Plated / Nickel Plated / Plated Tin / Silver Plated |

| Special Features | OEM Service Offered |

| Usage | Connecting Cable |

| Lead Time | 30 Days |

| Trademark | OEM |

| Origin | Xiamen, China |

| Production Capacity | 10,000 PCS/Day |

Production Process:

-

Material Selection and Preparation

High-quality copper is chosen based on the specific conductivity, durability, and strength requirements. The material is precision-cut and prepared for stamping.

-

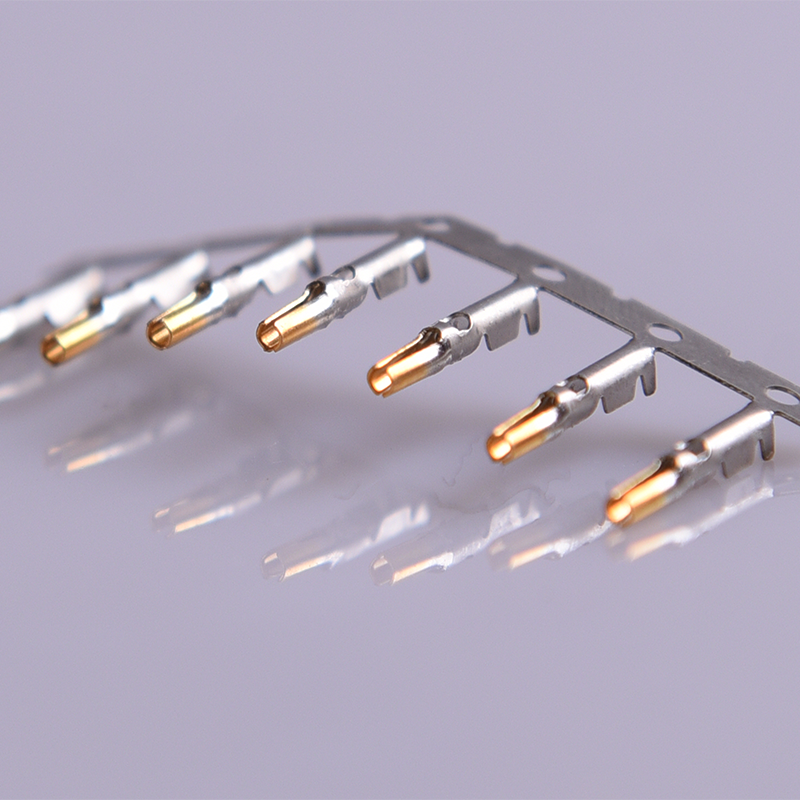

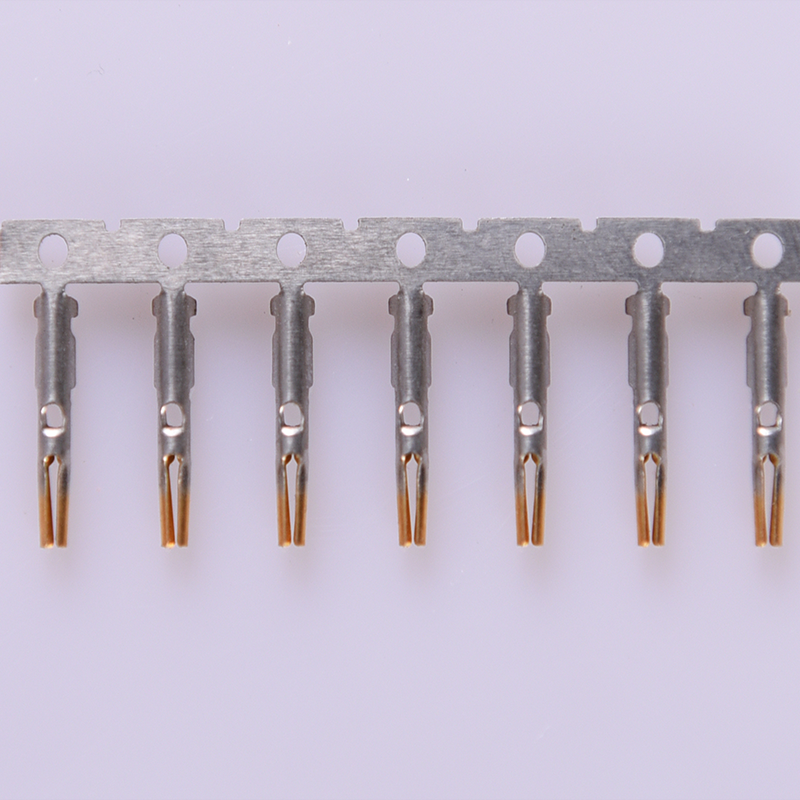

Progressive Stamping

Using advanced progressive stamping techniques, the copper sheet is processed through multiple die stations to form precise shapes, ensuring consistency and high dimensional accuracy.

-

Surface Treatment

Post-stamping, the connectors undergo surface treatments such as gold plating, nickel plating, or tin plating to enhance corrosion resistance, conductivity, and durability.

-

Quality Inspection

Rigorous quality checks are conducted at every stage, including dimensional verification, plating thickness measurement, and functional testing to meet industry standards.

-

Custom Modifications

For specific customer requirements, additional processes such as bending, hole punching, or shape modifications are carried out to ensure tailored solutions.

-

Packaging and Delivery

Finished connectors are carefully packaged to prevent damage during transportation and prepared for timely delivery, ensuring readiness for integration into new energy applications.

Why Choose Us?

-

Innovative R&D Capabilities

Our dedicated research and development team continuously enhances manufacturing processes and reduces costs by implementing cutting-edge innovations and improvements.

-

Integrated Tooling and Die Development

By managing the entire tooling and die design and manufacturing process in-house, we maintain strict control over quality, precision, and operational efficiency.

-

Stringent Quality Assurance

Adhering to ISO 9001 and IATF 16949 standards, our production processes are designed to deliver consistent, high-quality results at every stage.

-

Comprehensive Product Inspection

Each product undergoes meticulous 100% inspection before shipping, ensuring it meets exact specifications and delivers exceptional reliability.

-

Reliable and Prompt Delivery

We excel in meeting delivery commitments, including expedited production for urgent orders, ensuring our clients receive their products on time, every time.

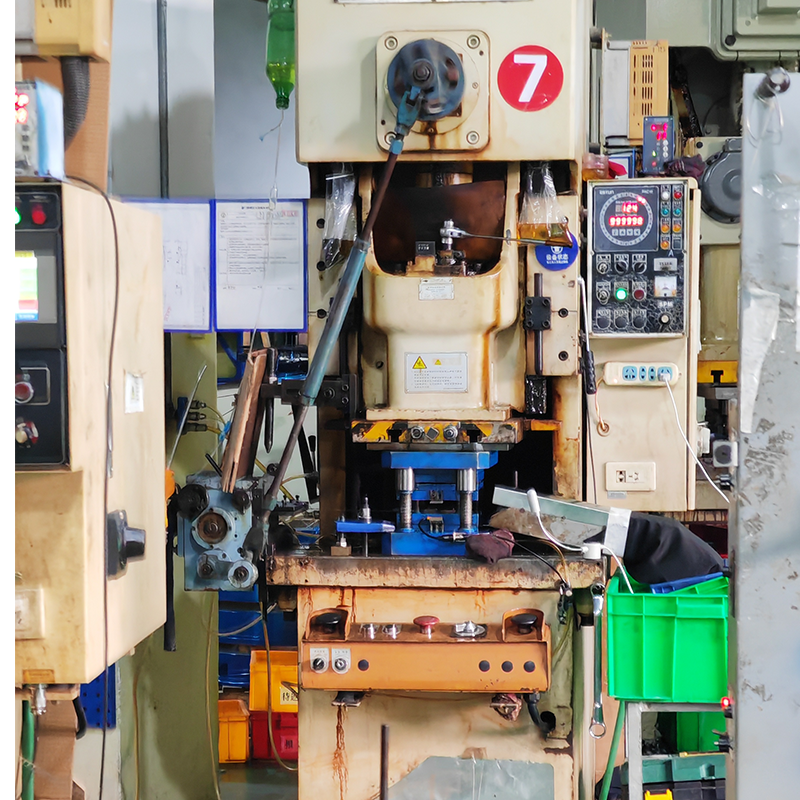

Factory Show:

Our advanced facilities are equipped to deliver top-quality production at scale. With 25 punch presses ranging from 25 to 300 tons, precision wire EDM machines, grinding tools, welding and polishing equipment, and ultrasonic cleaning systems, we ensure precision and reliability throughout the manufacturing process.

To enhance the performance and aesthetics of our metal stamping products, we provide a wide range of plating services, including electroplating, zinc plating, nickel plating, chrome plating, and anodizing. These processes improve durability, corrosion resistance, and surface appearance while meeting stringent industry standards.

By combining automated production lines, cutting-edge machinery, rigorous quality control protocols, and high-caliber plating techniques, we consistently deliver exceptional metal stamping products that meet and exceed customer expectations.