Overview:

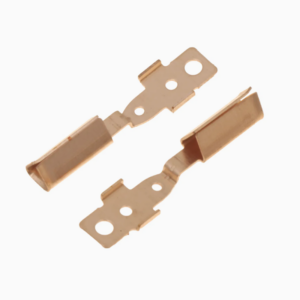

Our Golden Plating Stamped Lead Frames for IC Industry are expertly crafted from copper or brass, using precision metal stamping techniques and treated with gold plating for superior performance and reliability. Ideal for semiconductor packaging, these custom lead frames offer exceptional conductivity and durability. We provide OEM services, offering customized sizes, surface treatments, and metal stamping parts to meet the unique needs of your metal parts.

Details:

- Place of Origin: Xiamen, China

- Brand Name: OEM

- Service: OEM Services

- Processing Type: Metal Stamping

- Size: Customized Size

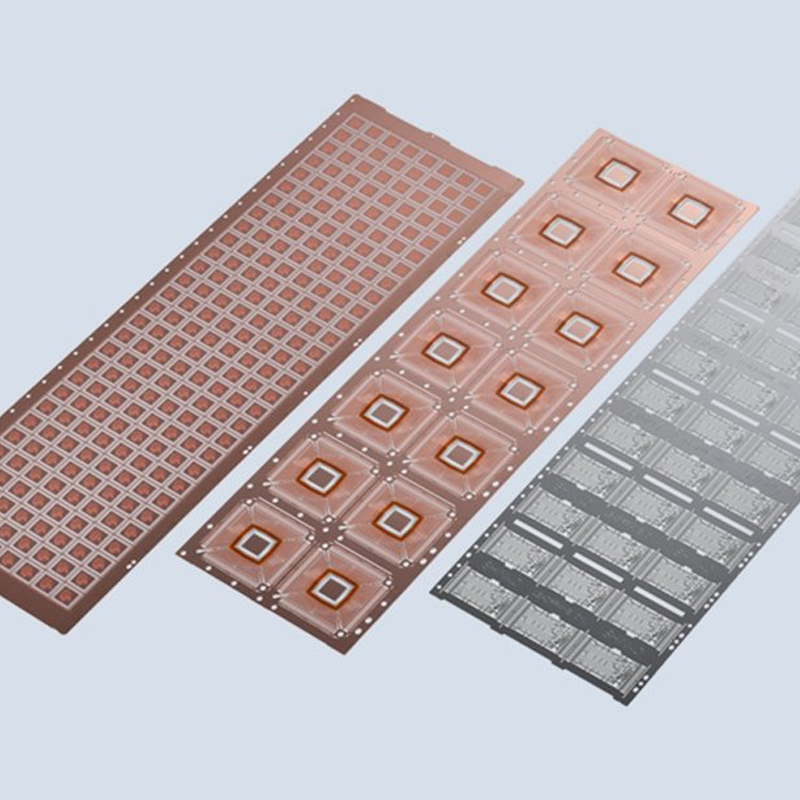

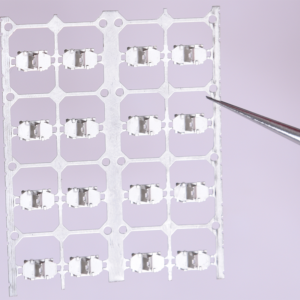

- Application: Semiconductor Package

- Frame Thickness: Custom

- Color: Custom

- Size Tolerance: ±0.025 mm

- Material: Copper

- QC Control: 100% Inspection

Production Process:

- Material Selection and Preparation: High-quality copper or copper alloy is selected for its excellent electrical conductivity and is pre-processed to the desired thickness and dimensions.

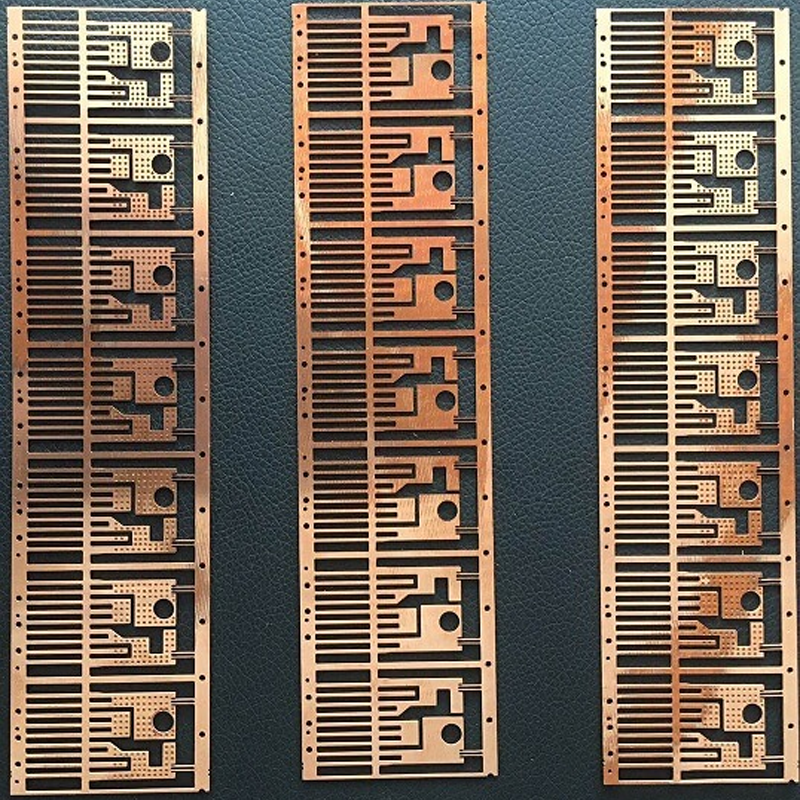

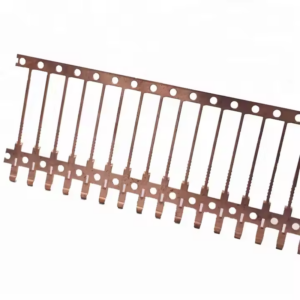

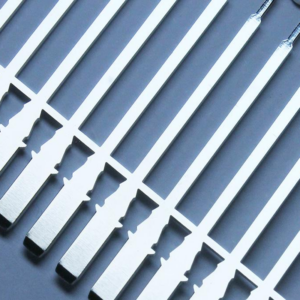

- Metal Stamping: The copper material is subjected to precision stamping using multi-step progressive dies to form the lead frame’s intricate patterns and components. This step ensures that the dimensions, shape, and design specifications are met.

- Etching: After stamping, the lead frame is often etched to create precise outlines and improve the surface for plating. This step ensures high-quality bonding and functionality for semiconductor packaging.

- Golden Plating: A thin layer of gold is electroplated onto the stamped lead frame. Gold plating provides excellent conductivity, corrosion resistance, and ensures the reliability of the lead frame in high-performance semiconductor applications.

- Inspection and Quality Control: The finished lead frame undergoes rigorous inspection processes, including visual checks and dimensional verification, ensuring that the lead frame meets the required specifications with tight tolerances.

- Final Packaging: The lead frames are carefully packed, ensuring they are protected from damage during transportation and handling before they are delivered to clients.

Post Process:

- Passivation: A chemical treatment that improves corrosion resistance by forming a protective oxide layer on metals, enhancing durability, especially in harsh environments.

- Silver Plating: A thin silver coating applied to improve electrical conductivity, corrosion resistance, and solderability, commonly used in electronics.

- Nickel Plating: Electroplated nickel provides increased hardness, wear resistance, and protection against corrosion, ideal for industrial and automotive parts.

- Tin Plating: A tin coating that enhances corrosion resistance and improves solderability, widely used in electronics to prevent oxidation.

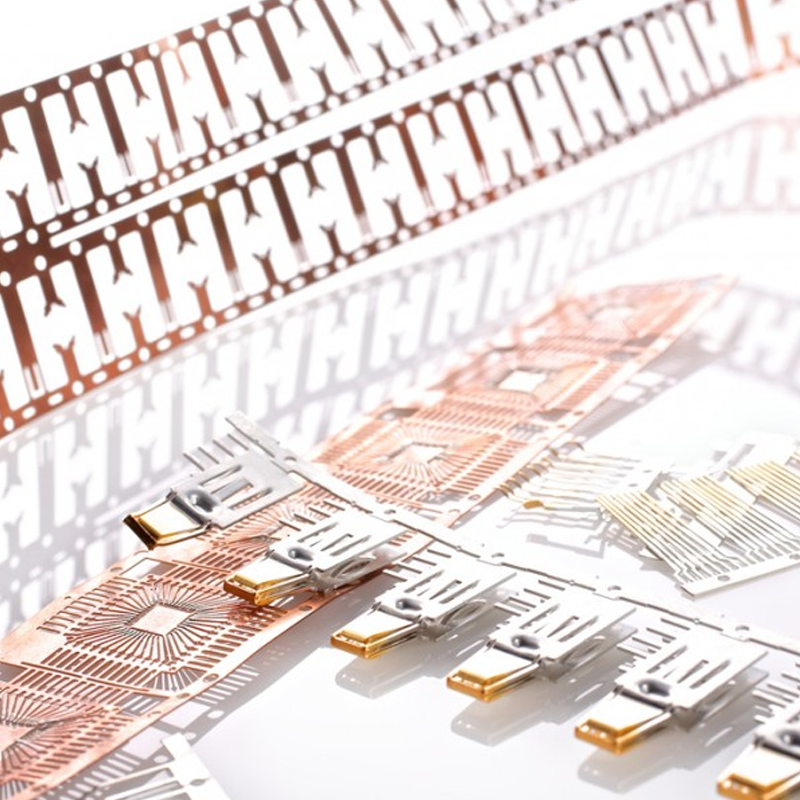

Factory Show:

We operate a fully equipped facility with 25 punch presses (25 to 300 tons), precision wire EDM machines, grinding equipment, welding and polishing tools, and ultrasonic cleaning systems to ensure top-quality production. Additionally, we offer a range of metal plating processes—including electroplating, zinc plating, nickel plating, chrome plating, and anodizing—to enhance durability, appearance, and functionality. Our advanced production lines, strict quality control, and state-of-the-art plating capabilities guarantee products that meet the highest industry standards.