Overview:

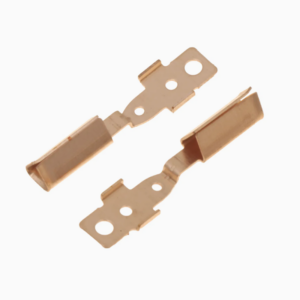

Aluminum 5052 Metal Stamped Sleeves are precision-engineered components made from high-quality Aluminum 5052 alloy, commonly used in deep drawing processes. These sleeves are manufactured through a series of progressive stamping operations to achieve the desired shape and size with tight tolerances. Aluminum 5052 is known for its excellent corrosion resistance, high strength, and formability, making it ideal for industries such as automotive, aerospace, marine, and electronics.

These stamped sleeves provide superior performance in demanding environments, offering durability, lightweight properties, and resistance to oxidation. Our factory offers custom services, including various material options, sizes, and surface treatments (e.g., anodizing, powder coating, or polishing) to meet specific customer requirements. With a focus on delivering high-quality components at competitive prices, we ensure the best value for your project.

Characteristics:

| Attribute | Details |

| Material | Aluminum |

| Application | Metal Recycling Machine, Metal Processing Machinery Parts, Metal Casting Machinery |

| Brand Name | OEM |

| Tolerance | +/-0.05mm |

| Shape | Custom |

| MOQ | Small Order Can Be Accepted |

| Lead Time | 20-25 Days |

| Transport Package | Plastic Bag + Carton |

| Specification | ISO9001 |

| Trademark | OEM |

| Origin | Xiamen, China |

Quality Test Process:

The quality test process for Aluminum-5052 metal stamped sleeves involves several key steps to ensure precision, durability, and consistency. First, incoming material is inspected using advanced tools like digital calipers and micrometers to verify its thickness, dimensions, and material composition. During production, our stamping process is monitored with automated inspection systems, including optical measurement equipment and coordinate measuring machines (CMM), to ensure dimensional accuracy and compliance with tolerances. Additionally, surface finishes are checked through visual inspection and equipment like surface roughness testers to ensure the required smoothness and integrity. Post-production, each batch undergoes 100% visual inspection and functional testing to check for defects such as cracks, deformation, or any surface imperfections. These rigorous quality checks, combined with our precision testing equipment, ensure that every Aluminum-5052 metal stamped sleeve meets the highest standards of performance and quality before it reaches the customer.

Surface Treatments:

- Anodizing – A process that creates a durable, corrosion-resistant oxide layer on the surface of aluminum, enhancing its appearance and providing long-lasting protection against wear and environmental elements.

- Powder Coating – A dry finishing process that applies a powder coating to the aluminum surface, offering improved durability, resistance to chipping, and a wide variety of color options for enhanced aesthetics and protection.

- Chromate Conversion Coating – A chemical treatment that provides corrosion resistance and improves adhesion for further coatings or paints, often used for aerospace and military applications.

- Polishing – A mechanical process that smooths and enhances the surface finish of the aluminum, providing a high-gloss, visually appealing appearance while also helping to reduce friction and improve wear resistance.

Our Advantages:

-

Cutting-Edge Research and Development

Our expert R&D team is committed to driving innovation, enhancing product performance, and optimizing manufacturing processes. We constantly strive to stay ahead of industry trends, helping us reduce costs and deliver superior products.

-

Comprehensive Tooling and Die Design

By managing the full tooling and die development process in-house, we maintain full control over quality, precision, and efficiency, ensuring flawless execution at every stage of production.

-

Strict Quality Control Standards

With adherence to ISO 9001 and IATF 16949 standards, we implement rigorous quality assurance measures to ensure that every product meets the highest industry benchmarks for reliability and consistency.

-

Thorough Product Inspection

All products undergo a 100% inspection process before shipment, ensuring that every item complies with strict specifications and delivers exceptional durability and functionality.

-

Reliable, On-Time Delivery

We prioritize punctuality, offering flexible production timelines to accommodate urgent orders and consistently meet delivery deadlines, ensuring that our clients receive their products exactly when expected.