Overview

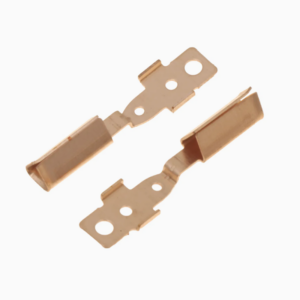

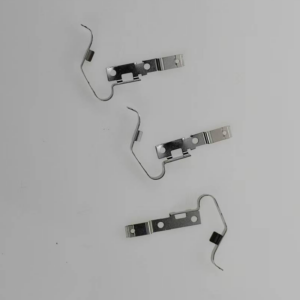

The car charger spring contact is a key component in automotive charging devices, designed to ensure a reliable electrical connection between the charger and the vehicle’s power source. Made from high-quality, durable metal, this spring contact features excellent conductivity and resilience, providing a secure and stable connection even under varying pressure and vibrations. Ideal for use in car chargers, it helps deliver efficient and uninterrupted power to mobile devices, ensuring a smooth charging experience.

Basic Information

– Surface Treatment: Electroplating

– Forming Process: Metal Stamping Parts

– Surface Finish Options: Nickel Plating, Sn Plating, Tin Plating, Zinc Plating

– Sample Availability: Available

– Tolerance: ±0.001 mm

– Size: Customizable as per requirement

– Application: Industrial, Furniture, Automotive, Motorcycle, etc.

– Manufacturing Approach: Metal Stamping, Cutting, Punching, Bending, Welding

– Transport Packaging: OPP Bag, Box, or Custom

– Specification: Customized

– Origin: Xiamen, China

OEM Services for Metal Stamping Parts

– Custom Design: We offer tailored design services for OEM metal stamping parts, leveraging advanced CAD software to create designs that align with your specifications and industry standards.

– Material Sourcing: Select from a diverse range of high-quality metals and alloys suited to your application requirements. Our team ensures that the chosen materials meet durability and performance criteria.

– Tooling and Die Fabrication: We develop precision tooling and dies using state-of-the-art machinery, ensuring high accuracy and consistency in part production. Our tooling process is optimized for both efficiency and quality.

– Manufacturing Capabilities: Our advanced metal stamping equipment handles various production volumes, from prototypes to large-scale runs, delivering parts with precise dimensions and reliable performance.

– Surface Finishing: Enhance the functionality and aesthetics of your stamped parts with our surface finishing options, including electroplating, polishing, and coating, tailored to meet your specific requirements.

– Quality Assurance: Rigorous quality control procedures are in place to ensure each part meets stringent standards. We conduct comprehensive inspections and tests to guarantee consistency and reliability.

– Custom Packaging and Logistics: We provide customized packaging solutions and manage logistics to ensure your parts are delivered securely and on schedule, according to your needs.

– Comprehensive Support: From initial consultation to post-production support, our dedicated team provides ongoing assistance to ensure your satisfaction and address any concerns that arise.

The Production Process for Our Metal Stamping Parts:

-

Order Receipt and Drawing Review

– Receive and review customer orders, including technical drawings in formats such as DXF, IGS, STEP, or PDF.

-

Design Confirmation

– Confirm design details with the customer to ensure accuracy before production begins.

-

Material Preparation

– Select and prepare metal sheets according to the required specifications.

-

Precision Cutting

– Utilize laser cutting and CNC shearing to cut metal sheets to precise dimensions.

-

Forming and Shaping

– Perform bending, punching, and stamping to achieve the desired shapes and features.

-

Welding and Riveting

– Join metal components using advanced welding techniques and riveting.

-

Surface Treatment

– Apply necessary surface treatments, including plating and spraying, to enhance durability and appearance.

-

Assembly and Quality Control

– Assemble the components and conduct rigorous quality checks to ensure adherence to specifications.

-

Packaging and Shipping

– Package finished parts securely and manage logistics for timely delivery to the customer.

-

After-Sales Support

– Provide ongoing support and address any post-delivery issues to ensure customer satisfaction.