Description:

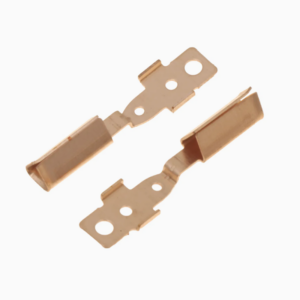

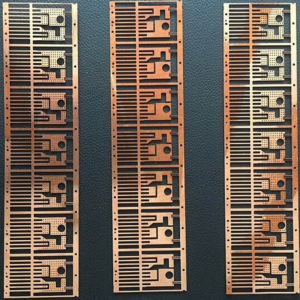

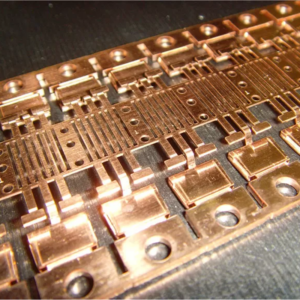

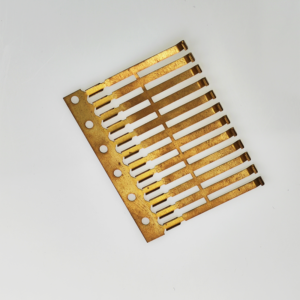

Tin plating metal lead frames for microprocessors are precision components primarily made from high-quality metals like copper, brass, or stainless steel, with a tin plating finish. The tin plating process provides excellent corrosion resistance, enhances electrical conductivity, and ensures reliable performance in demanding environments. These lead frames are widely used in microprocessor applications, where they facilitate the connection between the chip and the external circuitry, ensuring stable and efficient signal transmission.

Our custom lead frames come in a variety of sizes and shapes, tailored to meet your specific requirements. With the ability to handle high-volume orders of up to 50 million parts, we offer flexible production capabilities to accommodate both large and small-scale needs. Our tin-plated lead frames are engineered to meet the highest standards of quality and precision, ensuring optimal performance in microprocessor applications.

Features:

| Attribute | Details |

| Style | Creative |

| Processing | Metal Stamping |

| Color | Custom |

| Material | Copper |

| Brand Name | OEM |

| Design | Customized |

| Size | Custom Request |

| Sample Day | 5-7 Days |

| MOQ | Small Order Can Be Accepted |

| Shape | Custom Shape |

| Logo | Customized |

| Certification | ISO9001, OEM |

| OEM | Yes |

| Thickness | Customized |

| Export Market | Global |

| Transport Package | Standard Packaging |

| Origin | Xiamen, China |

| Production Capacity | 20,000 Pieces Per Week |

Production Process:

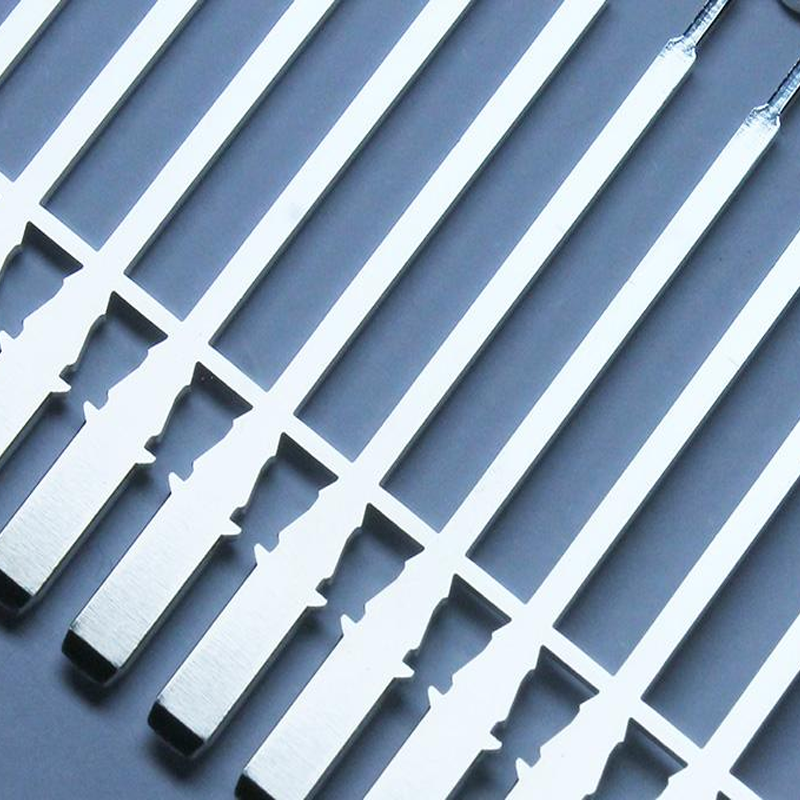

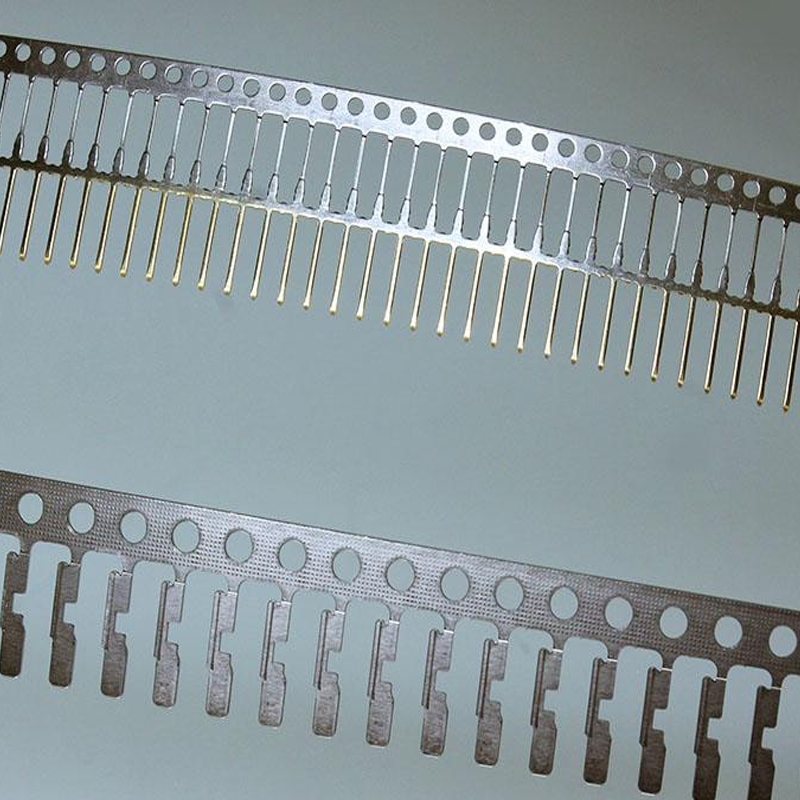

- Material Selection: The process begins with selecting high-quality copper or copper alloys as the base material, chosen for its excellent conductivity and durability.

- Metal Stamping: The selected material is subjected to metal stamping, where the lead frame is shaped and cut to precise dimensions using advanced stamping presses. This process ensures the lead frames meet the required specifications for microprocessor applications.

- Cleaning and Surface Preparation: After stamping, the lead frames are cleaned to remove any oils, debris, or contaminants. This step is critical to ensure a clean surface for plating and to achieve optimal adhesion.

- Tin Plating: The cleaned lead frames are then coated with a layer of tin using an electroplating process. The tin plating provides excellent corrosion resistance, enhanced solderability, and a reliable connection for microprocessor components.

- Quality Inspection: Following the plating process, the lead frames undergo rigorous quality inspections. These include visual checks, dimensional measurements, and adhesion tests to ensure that the tin plating is uniform and free from defects.

- Final Processing: Once the lead frames pass quality inspection, they may undergo additional processes such as trimming, bending, or assembly, depending on the customer’s specifications and application needs.

- Packaging and Shipping: Finally, the tin-plated lead frames are carefully packaged to prevent damage during transit and are ready for delivery.

Surface Treatment Options:

- Passivation: A chemical treatment process that enhances the corrosion resistance of stainless steel by forming a protective oxide layer on the surface. This treatment improves the durability and longevity of the lead frames in various environments.

- Gold Plating: A high-quality coating process that deposits a thin layer of gold onto the surface of the lead frame. Gold plating provides excellent conductivity, corrosion resistance, and enhanced solderability, making it ideal for high-performance electronic applications.

- Silver Plating: A plating method in which a layer of silver is applied to the metal surface. Silver plating offers superior electrical conductivity and corrosion resistance, ensuring reliable performance in microprocessor and semiconductor applications.

- Nickel Plating: A process where a layer of nickel is applied to the surface to enhance hardness, corrosion resistance, and wear protection. Nickel plating is often used to improve the durability and reliability of the lead frames in harsh environments.

Why Choose Us as Your Manufacturing Partner?

Tailored OEM & Comprehensive Assembly Solutions

With over two decades of industry experience, we specialize in providing custom OEM solutions and complete assembly services. Our sophisticated manufacturing capabilities are designed to meet your exact specifications, ensuring superior quality and optimal performance with every product.

Diverse Product Offering

We provide a broad range of products, including precision-stamped components, CNC-machined parts, springs, shafts, fasteners, and more. As your trusted, full-service manufacturing partner, we streamline operations to efficiently meet your diverse needs, from concept to final production.

Certified Industry Leader

As an established second-tier supplier, we have undergone comprehensive factory audits and uphold critical industry certifications, such as RoHS and HE compliance. This ensures that our products consistently align with global quality standards and regulatory requirements.

Unwavering Commitment to Quality

Our ISO 9001:2015 and IATF 16949 certifications reflect our dedication to maintaining stringent quality management systems. This guarantees that all parts we produce are crafted with precision and durability, consistently meeting the highest standards in every production run.