Overview:

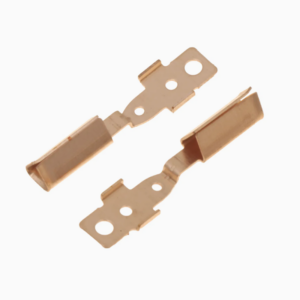

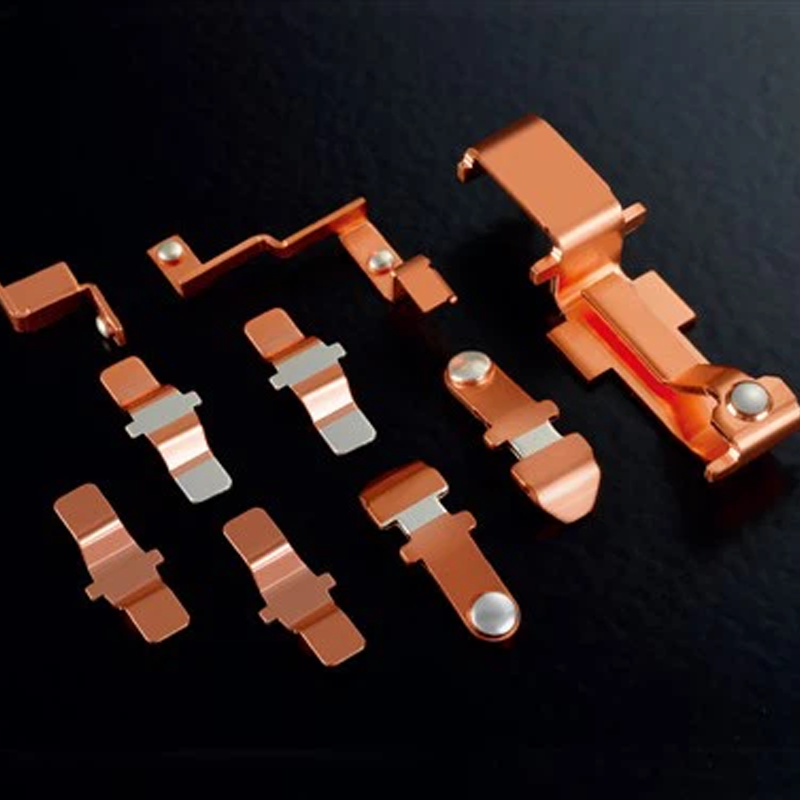

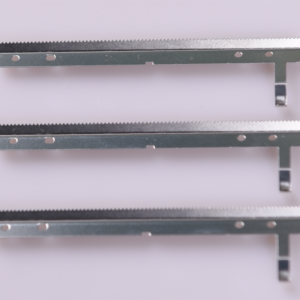

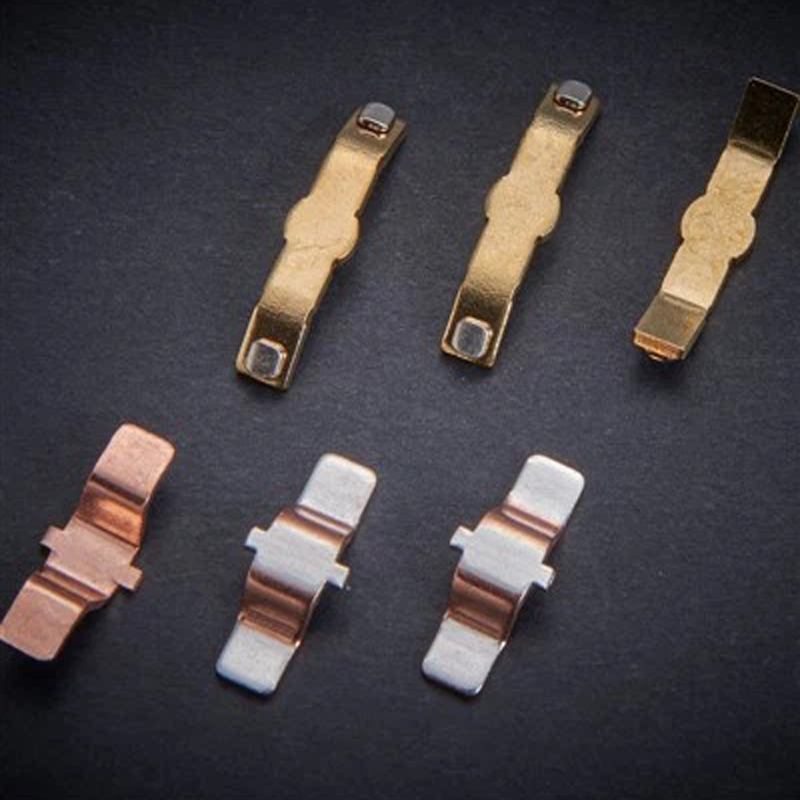

Custom electrical stamped contacts are precision-made components used in Electric Vehicle (EV) charging devices. These contacts are typically crafted from high-quality metals like copper, brass, or stainless steel, using advanced stamping techniques to ensure precision and durability. Plating processes such as gold, silver, or tin plating improve conductivity and corrosion resistance.

For EV charging, these contacts offer key advantages, including reliable electrical connections, long-lasting performance, and compliance with safety standards. They are engineered to withstand high-power charging cycles, ensuring efficiency and longevity.

The production of custom electronic connectors involves selecting materials, precision machining, stamping, plating, and assembly. This multi-step process ensures the creation of high-performance components suited for demanding applications like EV charging.

Characteristics:

- Item Name: Custom Electronic Stamping Parts

- Dimension: Based on customer’s drawing

- Craftsmanship: Stamping

- Finish: Plating

- Price: Real instant factory price

- Packing: Custom packaging

- Services: OEM available

Other Surface Treatment Options:

- Anodizing: A process that creates a durable, corrosion-resistant oxide layer on the surface of metals, typically aluminum. This treatment enhances wear resistance and provides a uniform, aesthetic finish.

- Sandblasting: A technique involving high-pressure abrasive particles to clean or texture the surface of a material. It improves surface roughness and adhesion properties, commonly used for improving coating adhesion or for a matte finish.

- Painting: The application of liquid paint to the surface of a part to provide corrosion resistance, aesthetic appeal, and additional protection. It is widely used for both functional and decorative purposes in various industries.

- Powder Coating: A dry finishing process where a powdered paint is applied to a part and then cured under heat. This results in a highly durable and uniform finish, providing excellent resistance to scratches, corrosion, and weathering.

Production Process:

- Material Selection: The first step is selecting the appropriate raw material, usually copper or copper alloys, to ensure high conductivity and durability for the electrical contacts.

- Stamping: Using precision stamping machines, the selected metal is cut and shaped into the required contact profiles. This step ensures the parts are made with high accuracy and meet the required specifications.

- Plating: After stamping, the contacts undergo plating processes such as nickel, gold, or silver plating. This enhances corrosion resistance, improves conductivity, and ensures long-term performance, especially in high-use environments like EV charging stations.

- Deburring & Cleaning: The stamped parts are deburred to remove any sharp edges and are thoroughly cleaned to eliminate oil, dust, or other contaminants that could affect the contact’s performance.

- Assembly: If the contacts are part of a larger assembly, they are assembled with other components, such as terminals or connectors, to create the final product.

- Quality Inspection: Rigorous quality checks are conducted at each stage of production, including dimensional and electrical testing, to ensure the parts meet industry standards and functional requirements.

- Packaging: The finished products are packaged according to customer specifications, ensuring safe handling and delivery.

Our Factory:

Our state-of-the-art manufacturing facilities are equipped with a comprehensive range of advanced machinery, including 25 punch presses (ranging from 25 tons to 300 tons), precision wire EDM machines, grinding equipment, welding and polishing tools, and ultrasonic cleaning systems. To further enhance the durability, appearance, and performance of our metal stamping products, we offer a wide array of plating processes, such as electroplating, zinc plating, nickel plating, chrome plating, and anodizing. These processes are conducted in our advanced plating facilities, ensuring consistent finishes, superior corrosion resistance, and strict adherence to industry standards. With a combination of automated production lines, cutting-edge equipment, and stringent quality control measures, we consistently deliver metal stamping products that meet the highest standards of precision and reliability.