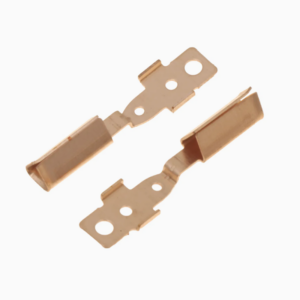

Overview:

Copper Stainless steel u clips with screws are versatile fasteners designed for secure assembly and reliable performance. These clips are crafted using precision stamping and bending techniques, utilizing high-quality copper and stainless steel materials for excellent durability, corrosion resistance, and mechanical strength. Commonly used in industries such as automotive, electronics, construction, and manufacturing, they provide robust solutions for fastening and structural support.

Our team specializes in precision manufacturing of metal clips and fasteners in various sizes to meet diverse application requirements. We offer custom solutions tailored to your specific needs, including clip size, shape, and material specifications, ensuring a perfect fit for your project. Contact us today for a competitive quote and expert assistance with your custom fastener needs.

Features:

- Material: Stainless Steel

- Size: Custom

- Certification: ISO, RoHS, SGS

- Available Materials: Brass, Carbon Steel, Stainless Steel

- Length: Custom

- MOQ: Based on your requirements

- Available Packing: Custom

- Trademark: OEM

- Origin: Xiamen, China

Finishing Options:

- Tin Plating: Provides superior corrosion resistance and excellent solderability, ideal for electrical and electronic components.

- Nickel Plating: Ensures enhanced durability, wear resistance, and an attractive finish for a variety of applications.

- Yellow Zinc Coating: Offers robust corrosion protection with an aesthetically pleasing golden appearance, suitable for industrial and automotive uses.

- Galvanization: Delivers exceptional rust and corrosion resistance, particularly for outdoor or high-moisture environments.

Quality Control Process:

The quality control process for copper stainless steel u clips with screw involves several critical steps to ensure precision and reliability. Initially, raw materials undergo a thorough inspection using spectrometers to verify compliance with required standards. During production, each stage is closely monitored, with dimensional accuracy checked using high-precision measuring tools like calipers, micrometers, and Coordinate Measuring Machines (CMM). Surface quality is evaluated with optical inspection equipment to detect scratches, burrs, or other defects. Thread and torque tests are performed to ensure screws meet performance requirements. Finally, finished products undergo a comprehensive visual and functional inspection to verify they meet design specifications and client requirements. These rigorous quality checks ensure the clips deliver optimal performance and durability across applications.

Why Choose Us?

At Plantmetal, we leverage advanced CAD/CAM software, CNC machining, and EDM technology to produce precision-engineered clips tailored to your specifications. Our team of seasoned tool and die makers ensures that every component, from a single prototype to a high-volume production run of up to 50 million parts, meets rigorous quality requirements. We implement thorough data collection at every stage of production and perform a detailed final inspection to guarantee flawless results.

With a commitment to delivering cost-effective solutions and just-in-time delivery, we provide clips that maximize performance and reliability. Contact us today to discover our full range of capabilities or request a quote to begin your custom project.