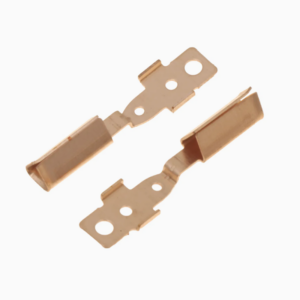

Overview:

Copper-5191 Stamped Terminal Connectors are essential components for efficiently transferring electrical current between circuits or systems. Used widely in battery storage devices, these high-precision connectors ensure reliable performance by delivering optimal electrical flow and real-time feedback. With their superior conductivity and durability, Copper-5191 terminals are designed to withstand the rigorous demands of modern technology, ensuring long-lasting functionality in critical applications. As a leading supplier of stamped metal parts, Plantmetal specializes in providing premium terminal connectors tailored for demanding industries, ensuring maximum performance and reliability.

Features:

| Attribute | Details |

| Application | Battery Storage Devices |

| Character | High Precision |

| Production Process | Progressive Stamping |

| Shape | Custom |

| Brand | OEM |

| Tolerance | +/- 0.01mm |

| Shipment Terms | Express / Air Freight / Sea Freight |

| Quality Control | 100% Inspection Before Shipping |

| Service | OEM |

| Dimensions | As Drawings or Samples |

| Certificates | ISO9001:2015, IATF16949, RoHS, etc. |

| Drawing Format | PDF, 2D/3D/DWG/IGS/STEP/SolidWorks |

| Transport Package | OPP bag, Custom |

| Trademark | OEM |

| Origin | Xiamen, China |

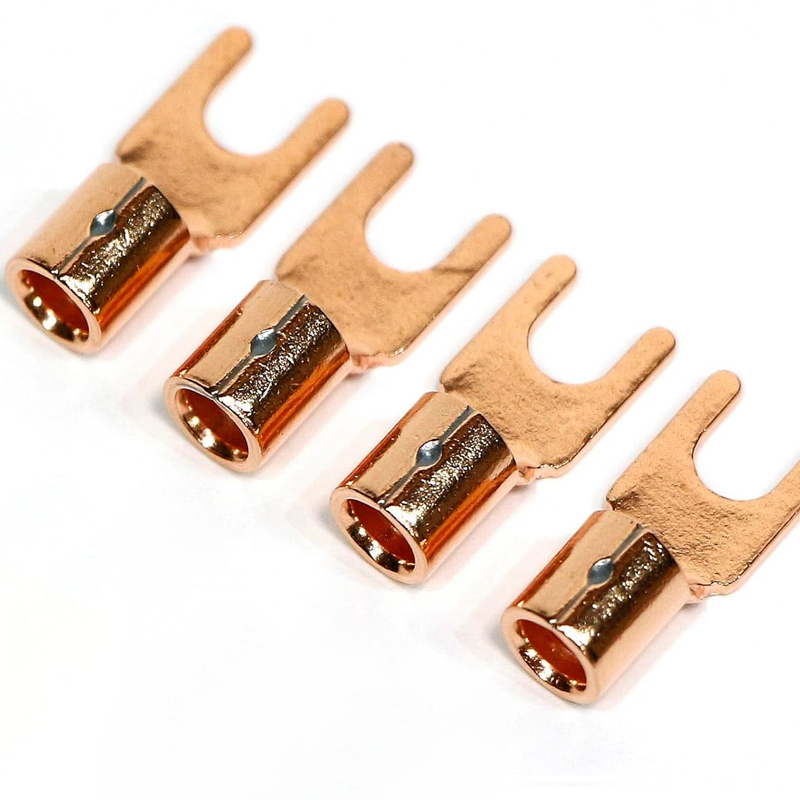

Finishing Options:

- Tin Plating– Provides corrosion resistance and enhances solderability.

- Nickel Plating– Improves durability, reduces wear, and provides additional corrosion resistance.

- Gold Plating– Ensures superior conductivity and reliability, ideal for high-performance connections.

- Silver Plating– Offers excellent conductivity and is often used for applications requiring high electrical performance.

Production Process:

- Material Preparation – The copper material is selected and prepared based on specifications, ensuring high-quality and optimal performance for the connectors.

- Progressive Stamping – Using precision progressive die stamping, the raw copper sheet is formed into the desired terminal shape with high accuracy.

- Plating – The stamped connectors undergo a plating process such as tin, nickel, gold, or silver plating, enhancing their corrosion resistance and conductivity.

- Inspection & Quality Control – Each terminal is inspected for dimensional accuracy and overall quality. A 100% inspection ensures compliance with stringent standards before shipment.

- Final Packaging – The finished Copper-5191 stamped terminal connectors are carefully packed for delivery, ensuring they arrive in excellent condition for further assembly or use in battery storage devices.

Our Factory:

We maintain a state-of-the-art production facility equipped with a diverse array of machinery to uphold the highest standards of quality in manufacturing. Our plant features 25 high-performance punch presses, ranging from 25 to 300 tons, alongside precision wire EDM machines, grinding equipment, welding and polishing tools, as well as advanced ultrasonic cleaning systems.

In addition to our robust manufacturing capabilities, we provide a wide range of metal plating options to enhance the durability, functionality, and appearance of our stamped metal products. These processes include electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our advanced plating facilities ensure consistent, high-quality finishes that meet rigorous industry standards for corrosion resistance and overall performance.

By combining automated production lines, cutting-edge mechanical equipment, and stringent quality control procedures, we are committed to delivering metal stamping products that meet the highest level of precision, reliability, and durability.