Overview:

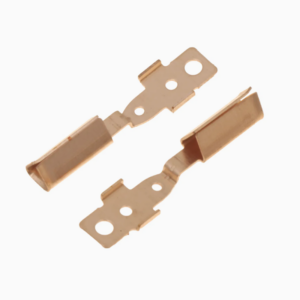

Polishing Stainless Steel Metal Stamped Brackets are high-precision components designed for a wide range of applications. These brackets are made through a combination of stamping, forming, and polishing processes to achieve a smooth, glossy finish and superior surface quality. The stamping process uses advanced machinery to cut and shape stainless steel into custom-designed brackets, while polishing ensures an aesthetic, smooth finish that also enhances corrosion resistance and durability.

As a leading manufacturer and supplier of custom metal brackets, we specialize in providing solutions that meet even the most stringent application requirements. Our capabilities include various design options, materials such as stainless steel, and a range of finishes to suit the specific needs of each project. Whether for industrial, automotive, or home appliance use, our polished stainless steel brackets deliver exceptional performance and quality.

Features:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Size | Customer’s Demand |

| Material | Stainless Steel, Cold Rolled Steel, Steel, Aluminum, Copper, Brass |

| File Formats | 3D/CAD/DWG/STEP/PDF |

| Type | OEM Parts |

| Standard | ISO9001, TS16949 |

| Thickness | 0.1-3.0mm |

Advantages of Brackets:

- Enhanced Durability

- Aesthetic Appeal

- Superior Strength

- Customization Flexibility

Production Process:

- Material Selection and Preparation

The appropriate stainless steel material is selected based on the required specifications. The material is then cleaned and prepared for stamping.

- Stamping

The stainless steel sheet is fed into a press, where it is shaped into the desired bracket form using precision dies and stamping tools.

- Polishing

After the brackets are stamped, they undergo a polishing process to enhance surface smoothness and achieve a high-quality finish, improving both appearance and corrosion resistance.

- Inspection and Quality Control

Each bracket undergoes thorough inspection to ensure it meets quality standards for size, strength, and surface finish.

- Packaging and Delivery

The finished brackets are packaged according to customer requirements and prepared for delivery.

Why Choose Us?

With years of experience, Plantmetal is a recognized leader in wire forming, providing exceptional customer service, unparalleled product quality, and quick turnaround times for all your wire forming needs. We maintain compliance with rigorous industry standards such as ISO 9001, ISO 14001, and TS-16949 certifications, ensuring precision and consistency across all stages of the manufacturing process. Through continuous monitoring and data collection, we guarantee the highest level of quality for every wire form we produce.

Our capabilities span a wide range of wire forms, from simple designs to complex, custom shapes and sizes. Whether you require prototypes or high-volume production, we are fully equipped to handle orders of up to 50 million parts with reliability and efficiency.

Contact us today to see how our wire forming expertise can elevate your next project!