Overview

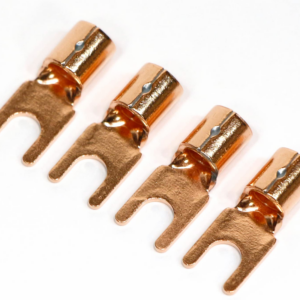

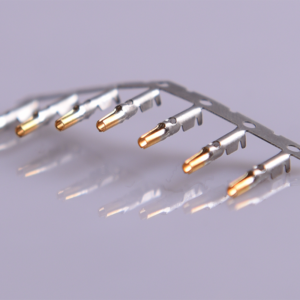

Ring terminal connectors are electrical components designed to securely connect wires to studs or terminal blocks, ensuring a stable and reliable electrical connection. These connectors feature a metal ring that allows easy attachment using a bolt or screw, providing excellent conductivity and corrosion resistance. The manufacturing process involves precision stamping, crimping, and plating with materials like copper or brass to ensure durability and compliance with industry standards. Ring terminal connectors are widely used in automotive, industrial, and electrical applications for safe and efficient wiring installations.

Basic Information

– Surface Treatment: Electroplating

– Forming Process: Metal Stamping Parts

– Surface Finish Options: Nickel Plating, Sn Plating, Tin Plating, Zinc Plating

– Sample Availability: Available

– Tolerance: ±0.001 mm

– Size: Customizable as per requirement

– Application: Industrial, Furniture, Automotive, Motorcycle, etc.

– Manufacturing Approach: Metal Stamping, Cutting, Punching, Bending, Welding

– Transport Packaging: OPP Bag, Box, or Custom

– Specification: Customized

– Origin: Xiamen, China

Quality Control Process for Metal Stamping

-

Incoming Material Inspection

– Description: Evaluate raw materials for compliance with specifications and quality standards before production. This includes testing material properties such as thickness, hardness, and chemical composition.

-

Pre-Production Sampling

– Description: Conduct initial trials and inspections on pre-production samples to ensure that the stamping process and tooling produce parts within the required tolerances and quality levels.

-

In-Process Monitoring

– Description: Implement continuous monitoring during production to ensure that the stamping process remains consistent. This includes checking for defects like warping, misalignment, and dimensional accuracy.

-

Dimensional Inspection

– Description: Use precision measuring instruments such as calipers, micrometers, and CMMs (Coordinate Measuring Machines) to verify that parts meet specified dimensions and tolerances.

-

Functional Testing

– Description: Test parts for proper functionality, ensuring they meet the required performance criteria. This may include checks for fit, alignment, and operational integrity.

-

Surface Quality Inspection

– Description: Inspect the surface finish of parts for defects such as scratches, dents, or coatings issues. This includes visual inspections and using tools to assess surface texture and coating integrity.

-

Post-Production Testing

– Description: Conduct additional tests on completed parts, including stress and load tests, to confirm durability and reliability under real-world conditions.

-

Final Inspection and Approval

– Description: Perform a comprehensive final inspection before shipping, ensuring that all parts meet quality standards and specifications. Approve or reject parts based on this thorough evaluation.

-

Documentation and Reporting

– Description: Maintain detailed records of quality control inspections and tests. Document any defects or non-conformance issues and report them for corrective actions.

-

Feedback and Continuous Improvement

– Description: Review quality control data to identify trends and areas for improvement. Implement corrective actions and process improvements to enhance overall product quality and efficiency.

Why Choose Us?

Industrial Experience

We have been specializing in the spring industry since 1998, bringing years of expertise and knowledge to our field.

Sample Availability

We can provide samples for your approval within 7 days. Samples are free of charge if we have the tool readily available.

Fast Delivery

Our standard delivery time is typically within 10 days.

Exceptional Service and Quality

Our business philosophy is centered on offering the best competitive pricing, excellent service, and superior quality.