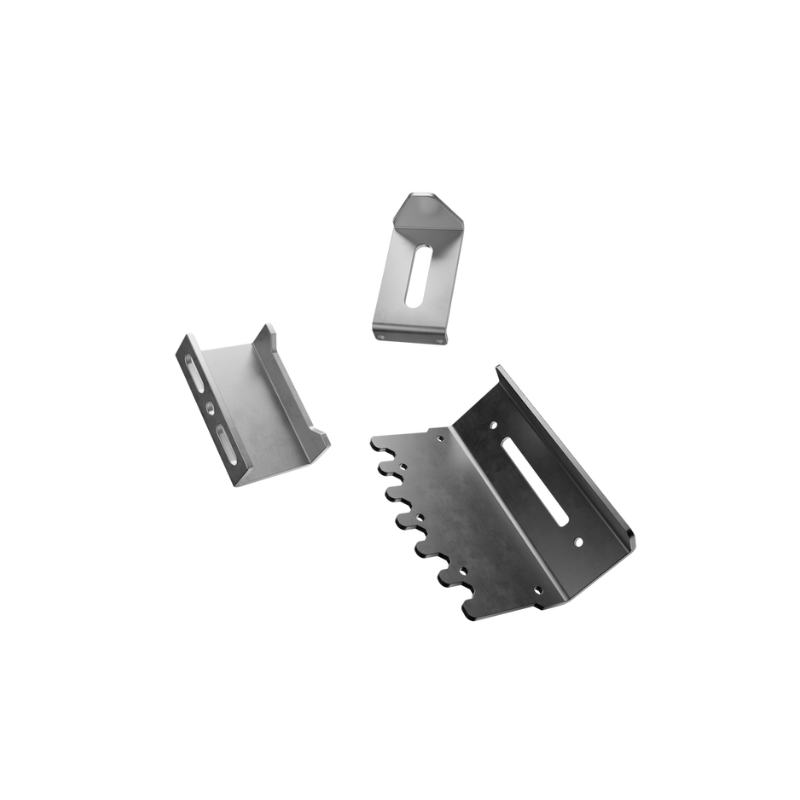

At Plantmetal, we specialize in precision steel bending, providing high-quality, custom solutions to meet the diverse needs of industries ranging from automotive to construction. Steel bending is a crucial manufacturing process that shapes steel into various forms and angles, enabling the creation of components essential for structures, machinery, and vehicles. With years of experience in delivering reliable and precise steel bending services, we know the importance of this technique in ensuring both functionality and aesthetic appeal in the final product. In this blog, we’ll dive deeper into the steel bending process, its various types, and how we at Plantmetal use it to empower industries worldwide. Let’s explore how this technique can be the key to your next project’s success.

What Is Steel Bending?

Steel bending is a manufacturing process that involves applying force to steel in order to achieve specific curves or angles. This technique is fundamental in shaping steel to meet the technical requirements of numerous applications, including infrastructure, machinery, and consumer products. At Plantmetal, we understand the importance of steel bending in ensuring that every component we produce meets stringent quality standards, whether it’s a simple structural part or a complex industrial component.

Steel bending requires precision to retain the material’s strength and durability while shaping it. It’s not just about achieving the right angle; it’s about doing so in a way that preserves the steel’s integrity and guarantees long-term performance. The versatility of steel bending allows for both intricate designs and robust, load-bearing structures.

Types of Steel Bending

Steel bending can be performed using a variety of techniques, each suited for different types of steel and intended uses. Below, we’ve outlined some of the most common methods we use at Plantmetal to achieve high-precision bends that meet our clients’ needs.

-

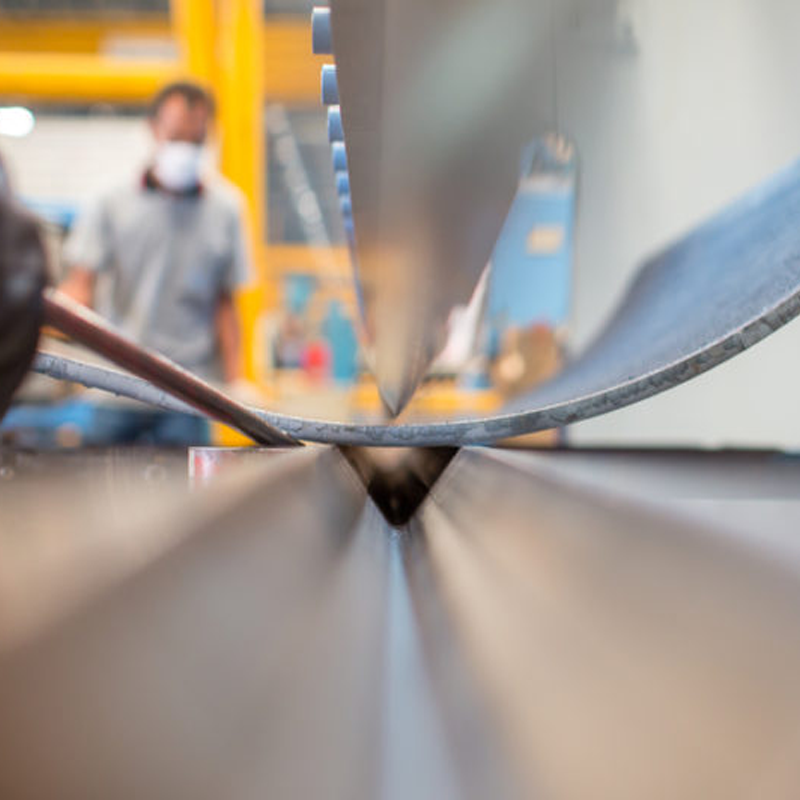

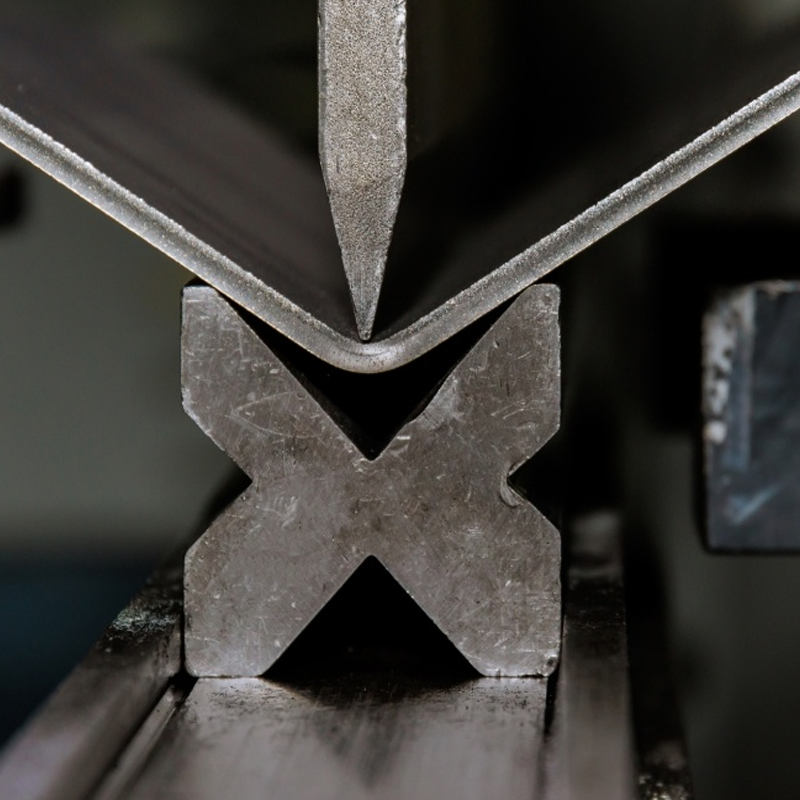

Press Brake Bending

Press brake bending is one of the most widely used techniques for bending sheet metal. A press brake machine applies force to steel by using a combination of punches and dies, forming the material into the desired shape or angle. At Plantmetal, we use press brake bending to create precise, repeatable bends for a variety of applications, from architectural elements to machinery components. This method offers exceptional control, allowing us to produce complex patterns while maintaining high precision.

-

Roll Bending

Roll bending is employed to shape large sheets of steel into smooth, continuous curves. By passing the material through a set of rollers, the steel is gradually deformed into the desired shape. This technique is ideal for creating large-radius bends, such as those found in tanks, pipes, and structural beams. At Plantmetal, we use roll bending for large-scale projects where smooth, even curves are required without sacrificing structural integrity.

-

Rotary Draw Bending

Rotary draw bending is typically used for bending tubes or pipes with precision. The steel is drawn around a die to create a consistent curve, allowing for tighter bends with highly accurate radii. This method is essential for industries like plumbing, automotive exhaust systems, and aerospace, where exact measurements and precise angles are critical. Plantmetal excels in rotary draw bending, ensuring that every bend is clean, uniform, and meets the exact specifications.

-

Mandrel Bending

Mandrel bending is an advanced form of rotary draw bending. In this method, a mandrel (a rod or ball) is inserted into the tube to support the walls as the steel is bent. This prevents the material from collapsing or deforming during the bending process, making it ideal for high-precision applications that require strict material integrity. At Plantmetal, we use mandrel bending to produce tubes and pipes that demand superior strength and quality.

-

Induction Bending

Induction bending is a process that uses heat and pressure to bend steel. An induction coil heats a localized section of the material to a specific temperature, allowing the steel to become more pliable. The heated section is then bent, and the material is rapidly cooled to maintain its shape. This technique is particularly useful for large structural components like steel beams, where strength is a priority. At Plantmetal, we rely on induction bending to produce large, load-bearing parts that require maximum durability and minimal stress points.

How Does Steel Bending Work?

The steel bending process involves several stages, each crucial to ensuring that the final product meets the desired specifications. Here’s an overview of the typical steps involved in steel bending:

-

Material Preparation

Before beginning the bending process, the steel must be properly prepared. This involves measuring, marking, and sometimes cleaning the material to ensure that the bends are made at precise angles and locations. For certain projects, the steel may need to be treated to enhance its malleability or to prevent surface damage during bending.

-

Machine Setup

The type of bending machine used depends on the specific bending method and the requirements of the project. Whether it’s a press brake, roll bender, or rotary draw bender, the machine must be set up with the right dies and tools. At Plantmetal, we ensure that every machine is calibrated to achieve the required bend and that the tools are in optimal condition for the task at hand.

-

Heating (When Necessary)

Some types of steel bending, particularly induction bending, require the material to be heated to make it more pliable. The steel is heated to a specific temperature to ensure that it bends without cracking or distorting. Plantmetal utilizes advanced temperature control systems to ensure uniform heating, which is essential for achieving consistent results.

-

Bending Process

Once the material is prepped and the machine is set up, the bending process begins. Steel is fed into the machine, and the necessary force is applied to achieve the desired shape. Whether it involves pressing, rolling, or drawing the steel, each technique has its specific advantages depending on the project.

-

Checking and Adjustments

After the bend is made, the steel is carefully checked to ensure it meets the required specifications. We measure angles, radii, and dimensions to ensure that every bend is perfect. If necessary, we make adjustments to correct any inaccuracies.

-

Finishing

Once the bending process is complete, the steel may undergo additional treatments such as cleaning, deburring, or applying protective coatings. At Plantmetal, we conduct a final inspection to ensure that the product meets the highest quality standards before it is shipped to the client.

Tips for Successful Steel Bending

At Plantmetal, we’ve gathered years of experience in perfecting the steel bending process. Here are some essential tips for achieving the best results:

- Know Your Material – Understanding the steel’s properties (e.g., yield strength, ductility) is critical for determining the best bending approach.

- Proper Preparation – Clean and treat the steel before bending to prevent defects during the process.

- Select the Right Tools – Choose the appropriate dies and tools for the steel grade and thickness to achieve clean, precise bends.

- Control Speed and Pressure – Adjust machine settings to avoid damaging the material or causing improper bends.

- Regular Maintenance – Keep machines in good working order to avoid breakdowns and ensure consistent performance.

- Check for Accuracy – Measure bends during the process to ensure they meet exact specifications.

- Plan for Springback – Compensate for the natural tendency of steel to “spring back” after bending.

- Test Prototypes – Run tests on a sample before full-scale production to catch potential issues early.

- Prioritize Safety – Always follow safety protocols to protect workers and equipment.

Conclusion

At Plantmetal, we pride ourselves on our expertise in steel bending. Whether you’re looking for large-scale structural components or precise, intricate bends, our team has the knowledge and equipment to deliver high-quality results. Reach out to us today to discuss how our steel bending services can support your project and help you achieve exceptional outcomes. Let us provide you with the solutions that meet your exact needs and exceed your expectations.