Overview:

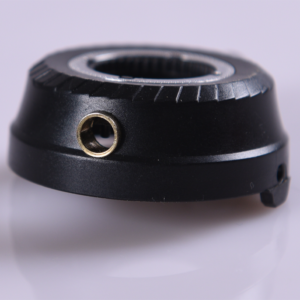

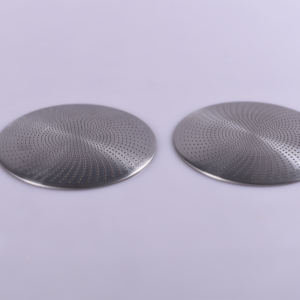

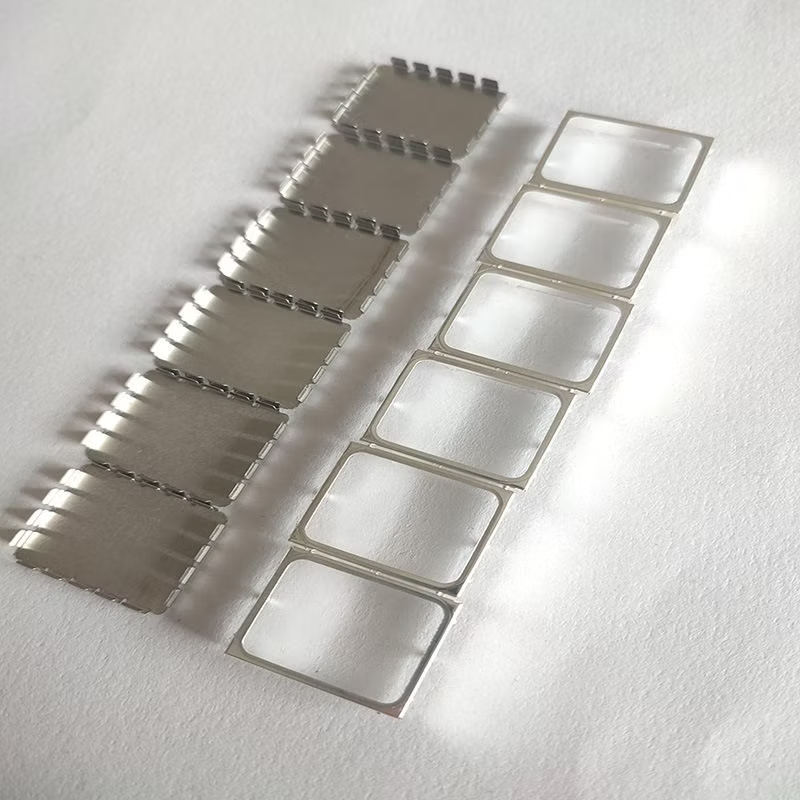

High Shielding Performance Metal Stamping Shields are precision-engineered components designed for effective electromagnetic interference (EMI) protection. Made from materials like stainless steel, copper, or aluminum, these shields are produced using advanced stamping processes to ensure high quality and custom fit. As a leading manufacturer and supplier, we specialize in delivering durable EMI shielding solutions tailored to your needs.

In the Electric Industry, these shields safeguard electronic circuits from interference, enhancing performance and ensuring compliance. Our factory offers OEM and custom solutions for these metal shields. Contact us to customize your EMI shielding requirements.

Features:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | Brass, Stainless Steel, Aluminum, Copper, Copper Alloys |

| Service | Custom/OEM Services |

| Package | Custom Package |

| Dimension | Customized Dimension |

| Certificate | ISO 9001, IATF16949 |

| Quality | 100% Guaranteed |

Advantages of Our Shields:

- Anti-singnal interference

- Good Quality

- Wide Range of Sizes

- Cost-Effective Manufacturing

Surface Treatment Options:

- Nickel Plating: Enhances corrosion resistance and surface hardness, ideal for aerospace, automotive, and electronics.

- Electrophoretic Coating (E-Coating): Provides a uniform, corrosion-resistant layer, commonly used in automotive and industrial applications.

- Zinc Plating: Protects against corrosion and rust, widely used in automotive, construction, and hardware industries.

Quality Assurance:

Quality assurance for high shielding performance metal stamping involves a comprehensive process to ensure product reliability and compliance with industry standards. Our production is certified under ISO9001 for quality management and IATF16949 for automotive industry standards, guaranteeing precise manufacturing and consistent performance. We utilize advanced testing equipment, including 3D coordinate measuring machines (CMM), tensile testers, and electromagnetic interference (EMI) testing devices, to verify the shielding effectiveness, durability, and dimensional accuracy of each component. These rigorous checks ensure that our metal shields meet the highest quality standards and deliver optimal performance in demanding applications.

Factory Show:

We operate a state-of-the-art facility equipped with advanced machinery to produce the highest quality metal stamping components. Our production line includes 25 punch presses with capacities ranging from 25 to 300 tons, precision wire EDM machines, grinding equipment, welding and polishing tools, as well as ultrasonic cleaning systems.

To enhance the durability, aesthetics, and functionality of our products, we offer a comprehensive range of advanced metal plating processes, including electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our cutting-edge plating facilities ensure consistent, high-quality finishes, superior corrosion resistance, and full compliance with industry standards.

Our robust manufacturing capabilities, combined with our ISO9001 and IATF16949 certifications, guarantee exceptional quality control and the consistent delivery of premium metal stamping products.