Description:

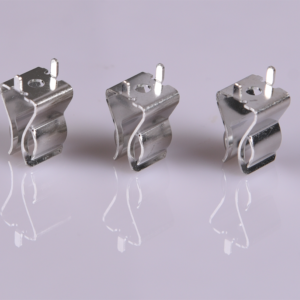

Progressive Stamping Flat Sheet Metal Spring Clips are precision-engineered components made from materials like high-carbon steel, stainless steel (301/304), or copper. Manufactured through a progressive die stamping process, these clips undergo multiple stages—cutting, forming, and bending—ensuring both efficiency and consistency. Surface treatments such as electroplating, coating, or heat treatment are applied to improve corrosion resistance and durability. These clips are commonly used in automotive (harness fastening), electronics (connectors), home appliances (structural components), and industrial equipment (mechanical clamping). We provide customized solutions to meet specific requirements, including adjustments in size, material, and surface treatment.

Features:

- Material: Copper, Stainless Steel, Carbon Steel, Aluminum, and more

- Mould: In-house die making for custom mold production

- Process: Progressive stamping for high-precision manufacturing

- Tolerances: ±0.02mm for tight dimensional accuracy

- Customization: Fully customizable to meet specific design and functional requirements

- Materials Available: Copper, Stainless Steel, Carbon Steel, Aluminum, etc

- Samples: Available upon request for evaluation

- Service: OEM (Original Equipment Manufacturer) services offered.

- File Formats: CAD, SolidWorks, PDF, and other industry-standard formats

- Transport Package: Custom packaging options available as per your requirements

- Trademark: OEM branding

- Origin: Xiamen, China

Surface Treatment Options:

- Galvanization: A zinc coating applied to steel to enhance corrosion resistance, providing long-lasting protection against rust and oxidation.

- Chroming: The process of applying a chromium coating, which improves surface hardness, enhances corrosion resistance, and delivers a high-gloss, visually appealing finish.

- Passivation: A treatment that increases the corrosion resistance of stainless steel by removing free iron from the surface, forming a protective oxide layer to safeguard against environmental degradation.

- Zinc-Nickel Alloy Plating: A robust, corrosion-resistant coating made from a zinc-nickel alloy, offering superior protection in harsh conditions and enhanced wear resistance.

Advantages of Metal Clips:

- Precision and Consistency: Manufactured to exact specifications, ensuring uniformity and reliable performance across every component.

- Enhanced Efficiency: Optimized production processes for faster turnaround times and cost-effective manufacturing.

- Material Flexibility: Available in a wide range of materials, offering versatility for various applications and environmental conditions.

- Tailored Design: Customizable to meet specific design requirements, ensuring the clip fits perfectly within your application’s needs.

Factory Overview:

Our facility is equipped with advanced machinery to maintain superior production quality. This includes 25 punch presses (ranging from 25 to 300 tons), precision wire EDM machines, grinding tools, welding and polishing equipment, and ultrasonic cleaning systems.

We offer a full suite of metal plating services, including electroplating, zinc plating, nickel plating, chrome plating, and anodizing, all supported by cutting-edge plating technology for consistent finishes, enhanced corrosion resistance, and industry compliance.

With automated production lines, rigorous quality control, and a commitment to excellence, our operations are ISO 9001 and IATF 16949 certified, ensuring the highest standards for our metal stamping products.