Overview

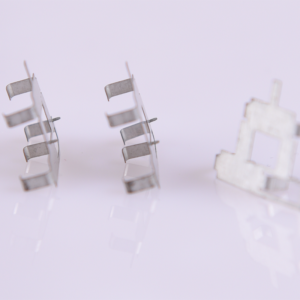

ABB electrical control cabinet conductive aluminum components are specialized parts made from aluminum, designed for use in electrical control cabinets. These components ensure efficient conductivity and heat dissipation, playing a key role in optimizing the performance and reliability of electrical systems. Typically, these aluminum parts are lightweight, durable, and resistant to corrosion, making them ideal for high-performance industrial and automation applications. ABB’s commitment to quality ensures these conductive aluminum components meet stringent standards, enhancing the overall efficiency and longevity of electrical control systems.

Specifications

Surface Treatments: Galvanized, nickel plated, black oxide, dacromet, chrome-plated, nylok, white washing, phosphate, gold plated, anti-corrosion coating, etc.

Sample Time: 7-12 days

Lead Time: 15-25 days

Payment Terms: T/T, L/C with 30% deposit, balance due before shipping

Packaging: Carton and pallet, customizable as per requirements

Delivery Methods: By sea or express

Quality Control Process for Metal Stamping

-

Incoming Material Inspection

– Description: Evaluate raw materials for compliance with specifications and quality standards before production. This includes testing material properties such as thickness, hardness, and chemical composition.

-

Pre-Production Sampling

– Description: Conduct initial trials and inspections on pre-production samples to ensure that the stamping process and tooling produce parts within the required tolerances and quality levels.

-

In-Process Monitoring

– Description: Implement continuous monitoring during production to ensure that the stamping process remains consistent. This includes checking for defects like warping, misalignment, and dimensional accuracy.

-

Dimensional Inspection

– Description: Use precision measuring instruments such as calipers, micrometers, and CMMs (Coordinate Measuring Machines) to verify that parts meet specified dimensions and tolerances.

-

Functional Testing

– Description: Test parts for proper functionality, ensuring they meet the required performance criteria. This may include checks for fit, alignment, and operational integrity.

-

Surface Quality Inspection

– Description: Inspect the surface finish of parts for defects such as scratches, dents, or coatings issues. This includes visual inspections and using tools to assess surface texture and coating integrity.

-

Post-Production Testing

– Description: Conduct additional tests on completed parts, including stress and load tests, to confirm durability and reliability under real-world conditions.

-

Final Inspection and Approval

– Description: Perform a comprehensive final inspection before shipping, ensuring that all parts meet quality standards and specifications. Approve or reject parts based on this thorough evaluation.

-

Documentation and Reporting

– Description: Maintain detailed records of quality control inspections and tests. Document any defects or non-conformance issues and report them for corrective actions.

-

Feedback and Continuous Improvement

– Description: Review quality control data to identify trends and areas for improvement. Implement corrective actions and process improvements to enhance overall product quality and efficiency.

OEM Services for Metal Stamping Parts

– Custom Design: We offer tailored design services for OEM metal stamping parts, leveraging advanced CAD software to create designs that align with your specifications and industry standards.

– Material Sourcing: Select from a diverse range of high-quality metals and alloys suited to your application requirements. Our team ensures that the chosen materials meet durability and performance criteria.

– Tooling and Die Fabrication: We develop precision tooling and dies using state-of-the-art machinery, ensuring high accuracy and consistency in part production. Our tooling process is optimized for both efficiency and quality.

– Manufacturing Capabilities: Our advanced metal stamping equipment handles various production volumes, from prototypes to large-scale runs, delivering parts with precise dimensions and reliable performance.

– Surface Finishing: Enhance the functionality and aesthetics of your stamped parts with our surface finishing options, including electroplating, polishing, and coating, tailored to meet your specific requirements.

– Quality Assurance: Rigorous quality control procedures are in place to ensure each part meets stringent standards. We conduct comprehensive inspections and tests to guarantee consistency and reliability.

– Custom Packaging and Logistics: We provide customized packaging solutions and manage logistics to ensure your parts are delivered securely and on schedule, according to your needs.

– Comprehensive Support: From initial consultation to post-production support, our dedicated team provides ongoing assistance to ensure your satisfaction and address any concerns that arise.