Overview:

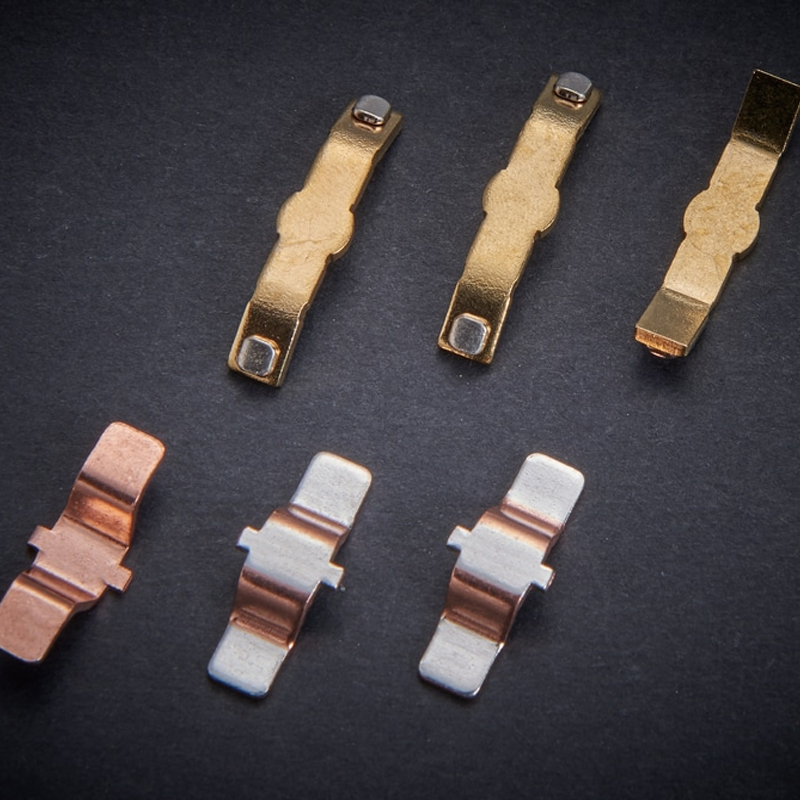

Silver Metal Stamping Electrical Contacts are precision-engineered for high-performance applications in industries like automotive, telecommunications, and consumer electronics. Made from premium silver alloys, these contacts offer exceptional conductivity and durability. As a leading manufacturer and supplier, we deliver high-quality, custom solutions to meet your specific requirements.

Features:

| Attribute | Details |

| Processing Type | Metal Stamping |

| Material | Copper, Brass |

| Mould | Multistep Progressive Dies |

| Surface Processing | Electroplating |

| Industry | Metal Stamping Parts |

| Tolerances | 0.02mm |

| Color | Customizable |

| Transport Package | Custom |

| Specification | According to client’s requirements |

| Trademark | OEM |

| Origin | Xiamen, China |

| Production Capacity | 1,000,000 units/day |

Production Process:

- Material Selection: High-quality silver or silver-plated materials are chosen for their excellent conductivity and corrosion resistance, which are essential for electrical applications.

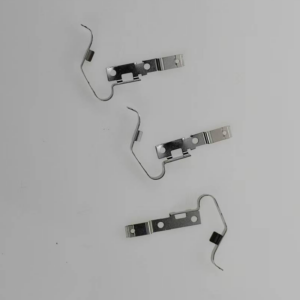

- Stamping: The metal is fed into progressive dies that use high pressure to stamp the material into the desired shape. The multistep progressive die process ensures precise and consistent production of electrical contact components.

- Surface Treatment: The stamped components undergo electroplating, where a thin layer of silver or other coatings is applied to enhance electrical conductivity, corrosion resistance, and durability.

- Forming: After plating, the contacts may go through additional forming processes, such as bending or shaping, to achieve the required final design and functionality.

- Inspection: Each contact is subjected to rigorous quality control checks, including dimensional verification, surface inspection, and electrical conductivity testing to ensure they meet industry standards.

- Packaging: The final products are carefully packaged to protect them from damage during transport and to preserve their quality until they reach the customer.

Post Process:

- Gold Plating: A high-quality coating process that enhances electrical conductivity and provides superior corrosion resistance for electronic components.

- Silver Plating: A durable, conductive plating option that improves the performance and longevity of electrical contacts, offering excellent corrosion resistance and high conductivity.

- Nickel Plating: A robust coating method that increases wear resistance, reduces corrosion, and enhances the durability of metal parts, making them ideal for high-performance applications.

- Tin Plating: A cost-effective plating solution that provides corrosion resistance and is commonly used for components exposed to harsh environments or for enhanced solderability in electronic assemblies.

Why Partner with Us?

- Industry Expertise: With over two decades of experience in metal mold design and precision stamping, we are committed to delivering exceptional manufacturing capabilities and superior quality products.

- Global Experience: Our extensive experience in serving international markets has allowed us to build a strong reputation for successful export operations and establish long-term global partnerships.

- Certifications & Quality Assurance: We hold ISO 9001 and IATF 16949 certifications, ensuring our processes align with the highest global standards of manufacturing excellence and continuous improvement.

- Environmental Compliance: All of our products meet RoHS (Restriction of Hazardous Substances) standards, and we provide comprehensive material reports to guarantee full compliance with environmental and safety regulations.