Overview

Boss speaker refers to a high-quality audio speaker produced by Boss Audio Systems, a brand known for its premium sound equipment. Boss speakers are designed to deliver powerful, clear sound with deep bass and crisp highs, making them popular in car audio systems, home audio setups, and portable speakers. The speakers are engineered with advanced materials and technologies to enhance durability and performance, ensuring long-lasting use even in demanding environments. Boss speakers are often praised for their affordability and impressive sound quality, making them a popular choice for both casual listeners and audio enthusiasts.

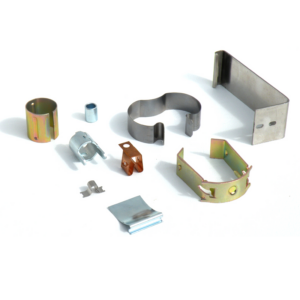

Basic Information

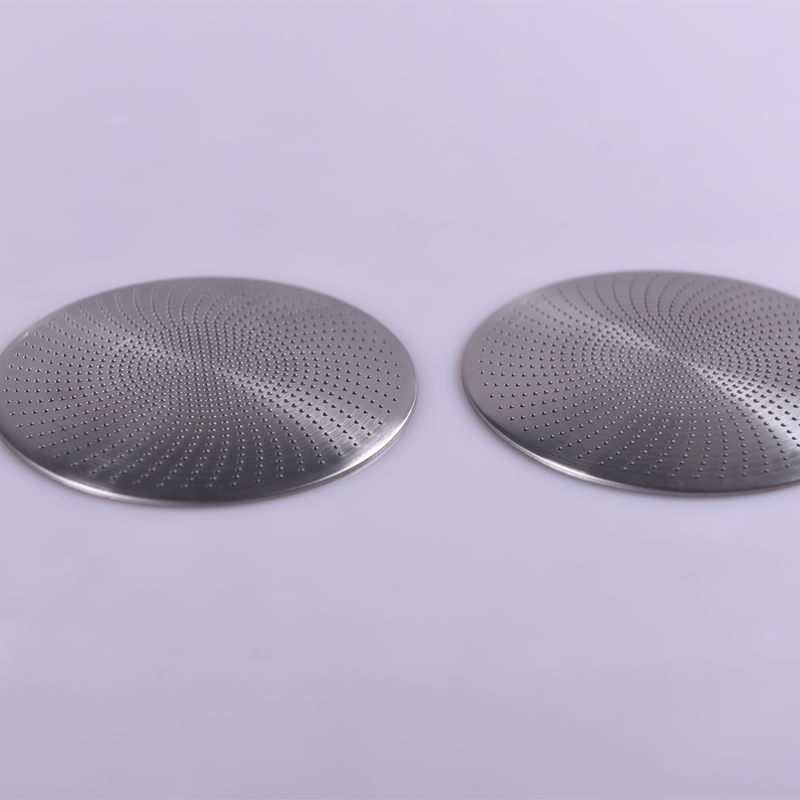

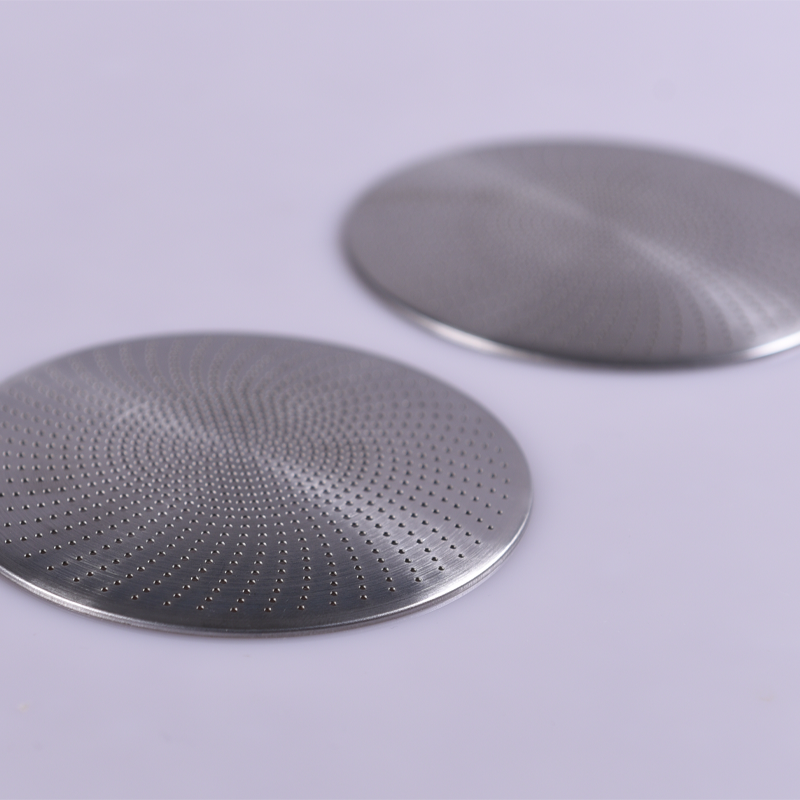

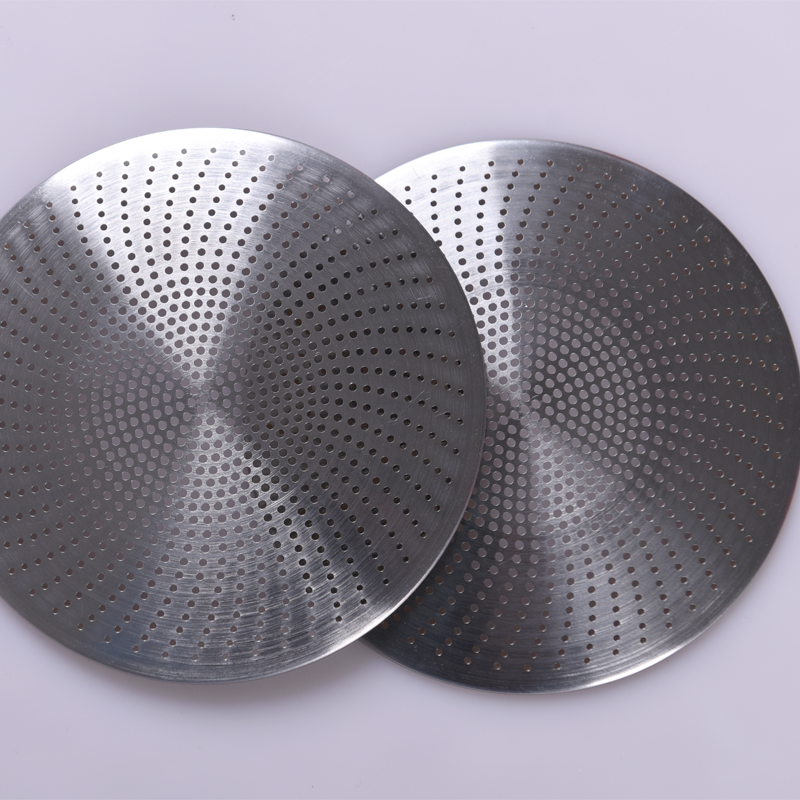

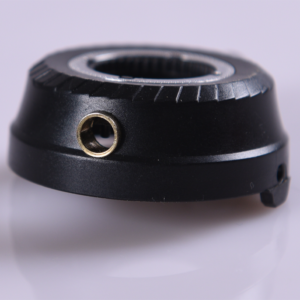

– Surface Treatment: Electroplating

– Forming Process: Metal Stamping Parts

– Surface Finish Options: Nickel Plating, Sn Plating, Tin Plating, Zinc Plating

– Sample Availability: Available

– Tolerance: ±0.001 mm

– Size: Customizable as per requirement

– Application: Industrial, Furniture, Automotive, Motorcycle, etc.

– Manufacturing Approach: Metal Stamping, Cutting, Punching, Bending, Welding

– Transport Packaging: OPP Bag, Box, or Custom

– Specification: Customized

– Origin: Xiamen, China

OEM Services for Metal Stamping Parts

– Custom Design: We offer tailored design services for OEM metal stamping parts, leveraging advanced CAD software to create designs that align with your specifications and industry standards.

– Material Sourcing: Select from a diverse range of high-quality metals and alloys suited to your application requirements. Our team ensures that the chosen materials meet durability and performance criteria.

– Tooling and Die Fabrication: We develop precision tooling and dies using state-of-the-art machinery, ensuring high accuracy and consistency in part production. Our tooling process is optimized for both efficiency and quality.

– Manufacturing Capabilities: Our advanced metal stamping equipment handles various production volumes, from prototypes to large-scale runs, delivering parts with precise dimensions and reliable performance.

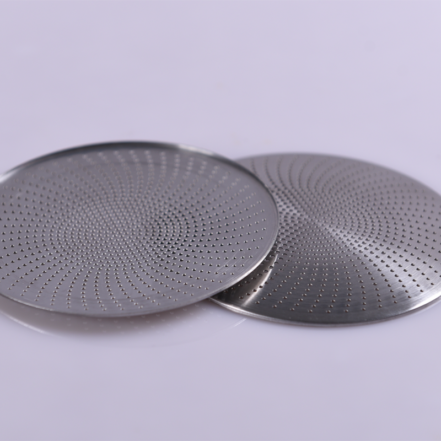

– Surface Finishing: Enhance the functionality and aesthetics of your stamped parts with our surface finishing options, including electroplating, polishing, and coating, tailored to meet your specific requirements.

– Quality Assurance: Rigorous quality control procedures are in place to ensure each part meets stringent standards. We conduct comprehensive inspections and tests to guarantee consistency and reliability.

– Custom Packaging and Logistics: We provide customized packaging solutions and manage logistics to ensure your parts are delivered securely and on schedule, according to your needs.

– Comprehensive Support: From initial consultation to post-production support, our dedicated team provides ongoing assistance to ensure your satisfaction and address any concerns that arise.

Factory Show

We operate a comprehensive range of plants and equipment to ensure the highest quality production. Our facilities are equipped with 25 punch presses ranging from 25 tons to 300 tons, precision wire EDM machines, grinding equipment, welding and polishing tools, and ultrasonic cleaning systems.

In addition to our manufacturing capabilities, we offer a variety of metal plating processes to enhance the durability, appearance, and functionality of our metal stamping products. These include electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our state-of-the-art plating facilities ensure consistent finishes, corrosion resistance, and compliance with industry standards.

This combination of professional and automated production lines, advanced mechanical equipment, rigorous quality control measures, and high-quality plating processes ensures we deliver metal stamping products of the highest standard.