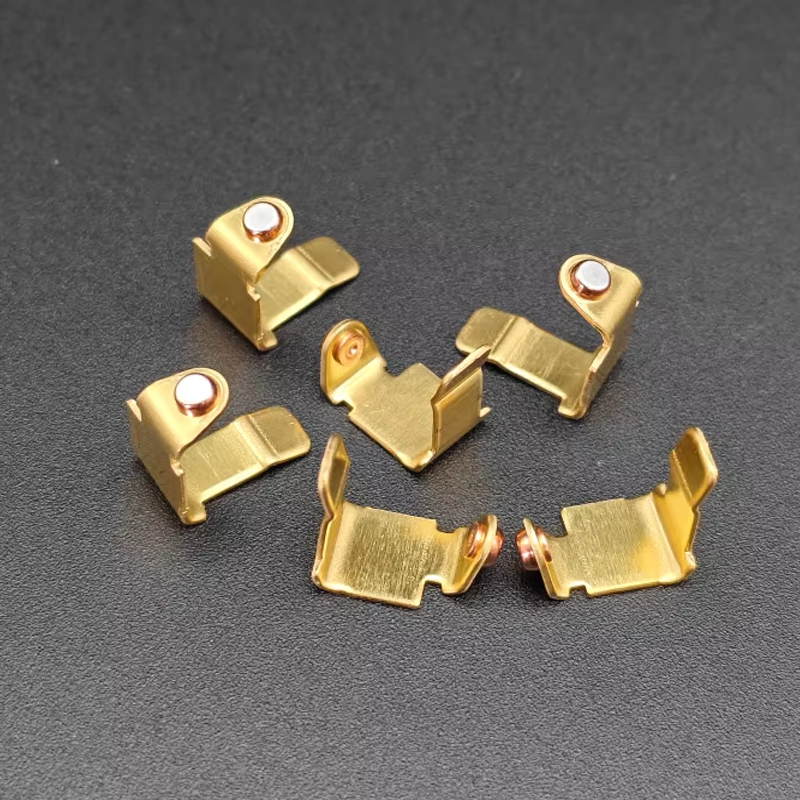

Overview:

Brass-6265 stamped electrical contacts are precision-engineered using a stamping process, where high-quality Brass-6265 alloy is shaped and cut using precision dies. This manufacturing technique ensures consistent quality, tight tolerances, and optimal conductivity. The stamping process is ideal for producing durable, high-performance contacts with excellent mechanical strength and corrosion resistance, making them suitable for demanding applications in telecommunications and other industries.

Characteristics:

| Attribute | Details |

| Material | Brass |

| Surface Processing | Silver Plating |

| Process | Metal Stamping |

| Industry | Electronics, Telecommunications |

| Tolerance | 0.02 mm |

| Customized | Yes |

| Size | Customized |

| Transport Package | Custom |

| Specification | ISO 9001: 2015, IATF16949 |

| Trademark | OEM |

| Origin | Xiamen, China |

| Production Capacity | 500,000 PCS/Month |

Production Process:

1. Material Selection

High-quality Brass-6265 is chosen for its superior conductivity, corrosion resistance, and durability, ensuring long-term performance in telecommunications applications.

2. Metal Stamping

The Brass-6265 material is fed into a stamping press, where it is precisely cut, shaped, and formed to create electrical contacts with tight tolerances and uniformity.

3. Surface Treatment (Silver Plating)

The stamped contacts are coated with silver plating to enhance conductivity, wear resistance, and corrosion resistance, ensuring reliable electrical connections.

4. Quality Control and Inspection

The contacts undergo rigorous testing for dimensional accuracy, surface finish, and electrical performance, ensuring compliance with industry standards like ISO 9001:2015 and IATF16949.

5. Customization and Final Adjustments

Contacts are customized to meet specific sizes, designs, and functional needs, with optional additional treatments or adjustments.

6. Packaging and Shipping

Finally, the contacts are carefully packaged to prevent damage during shipping and delivered to customers, ready for use in telecommunications applications.

Surface Treatment Options:

1. Silver Plating

Silver plating enhances the electrical conductivity, wear resistance, and corrosion protection of brass contacts, making them ideal for high-performance telecommunications applications.

2. Gold Plating

Gold plating provides excellent corrosion resistance, reduces contact resistance, and improves long-term reliability, especially in high-precision applications where performance consistency is crucial.

3. Nickel Plating

Nickel plating offers improved durability and resistance to oxidation, which is especially important for contacts exposed to harsh environmental conditions or requiring increased mechanical strength.

4. Tin Plating

Tin plating is often used for its cost-effectiveness and good solderability, ensuring strong, reliable electrical connections in environments where moderate durability and corrosion resistance are sufficient.

Our Factory:

Our manufacturing facilities are equipped with a comprehensive range of advanced machinery to ensure top-tier production quality. We operate 25 punch presses (ranging from 25 to 300 tons), precision wire EDM machines, grinding equipment, ultrasonic cleaning systems, and welding and polishing tools. Additionally, we utilize state-of-the-art testing equipment, including coordinate measuring machines (CMM), electronic testing devices, and optical measuring tools to guarantee product accuracy and consistency.

We also offer a variety of metal plating options to enhance the performance, appearance, and durability of our stamped components, including electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our plating facilities are fully equipped to meet industry standards for corrosion resistance and finish consistency.

With our ISO 9001:2015 and IATF 16949 certifications, along with automated production lines and rigorous quality control processes, we ensure the highest quality metal stamping products for diverse applications.