What is Metal Stamping Process?

Metal stamping is a precision manufacturing technique that involves shaping flat metal sheets or coils into specific components by placing the material between dies and applying force through a press. This process is highly versatile, capable of producing parts with a wide range of shapes and features. Depending on the complexity of the part, multiple stamping operations—such as bending, piercing, and drawing—may be necessary to achieve the desired form. The metal stamping process is known for its high production speed, consistency, and ability to produce intricate shapes with tight tolerances, making it an ideal choice for mass production.

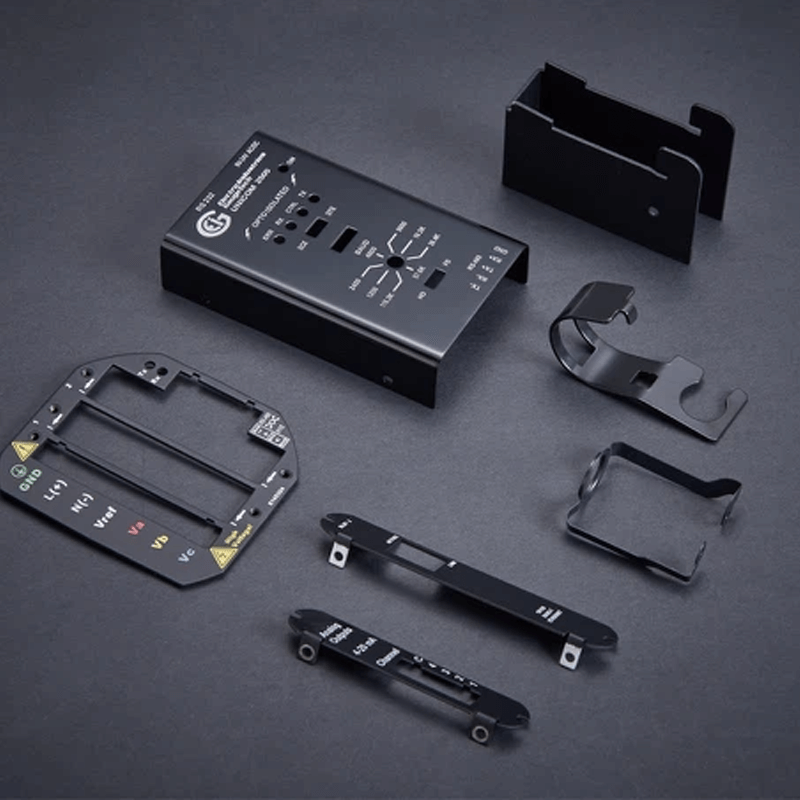

Advanced Custom Metal Stamping Services

At Plantmetal, we specialize in transforming metal into precisely what you need, whether it’s for small, intricate parts or more complex components. Our 6,000-square-meter stamping facility houses 26 punch presses, ranging from 25 to 800 tons, enabling us to produce over five million parts and manage orders of all sizes. We excel in low-volume metal stamping and precision metal fabrication.

Each stamping project is overseen by a dedicated engineering expert who will personally review your quote and oversee the process from start to finish. With dual certifications (IATF16949 & ISO13485), we ensure that you receive metal parts with exceptional precision and quality, while enjoying a seamless project management experience.

Metal Stamping Factory Highlights

| Press Rating | Minimum 25 tons | Up to 800 tons |

| Maximum Press Stroke(mm) | 250 | |

| Stamping Press Bed(mm) | Min | Max |

| 680*300 | 4500*1700 | |

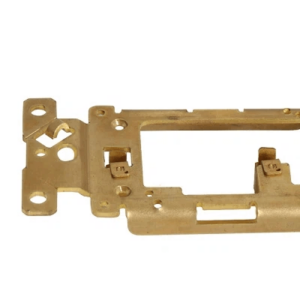

| Production Method | Single Hit Die | Forming |

| Progressive Die | Piercing | |

| Blanking | Punching | |

| Coining | Embossing | |

| Bending | Flanging | |

| Drawing | Overmolding | |

| Part Thickness | Min | Max |

| 0.012 in | 0.5 in | |

| Part Diameter | Min | Max |

| 0.012 in | 0.5 in | |

| Tolerance (+/-) | 0.001 in | |

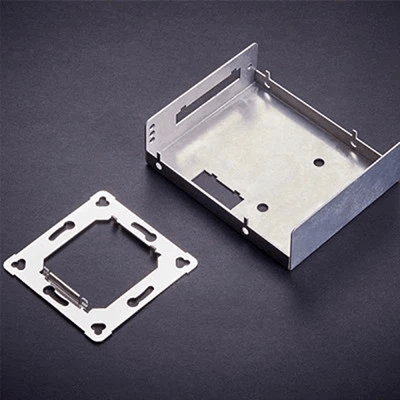

| Representative Products | Heat sinks | Furniture parts |

| Shrapnel | Automotive parts | |

| Contacts | Electrical switches | |

| Brackets | Electronic terminals | |

| Shrapnels | Medical components | |

| Metal clips | Sensor components | |

| Production Volume | Min | Max |

| MOQ | Free mold opening | |

| 10 units | Large Scale Production Volume | |

| Prototype | No cap on quantity | |

| Small Run | ||

| Quality Assurance | IATF16949:2016 | RoHS |

| ISO13485:2016 | Reach | |

| Material certificate | ||

| Inspection report |

Minimize Mold Costs with Plantmetal’s Factory

At Plantmetal, we offer a cost-effective solution for both new mold development and mold transfer projects. Take advantage of our complimentary mold sampling service, which allows you to assess mold design and product functionality at no extra cost. Our in-house design and manufacturing capabilities for stamping molds enable us to provide customized metal stamping solutions efficiently, delivering parts in virtually any shape or size with short lead times.

Metal Stamping Forming Materials

At Plantmetal, we offer an extensive selection of materials for our custom metal stampings. If you have specific material requirements, our experts are readily available to assist you in finding the perfect solution for your needs.

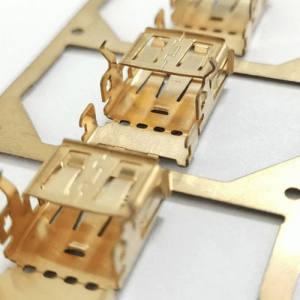

Copper

Our copper offerings include C110, known for its exceptional electrical conductivity and ease of forming, making it ideal for various applications. We also provide C510 phosphor bronze, a high-strength, wear-resistant copper alloy. Due to its superior electrical conductivity, copper is extensively used in electronic and electrical equipment.

Brass

We offer Brass 230 (85/15), commonly known as red brass, and Brass 260 (70/30), referred to as yellow brass, as prime materials for manufacturing stamped parts. These alloys are highly regarded for their excellent formability, corrosion resistance, and outstanding mechanical properties, making them ideal for a wide array of applications.

Stainless Steel

We work with a variety of stainless steel grades, including 301, 304, and 316/316L. Grade 301 stainless steel is known for its exceptional tensile strength, making it suitable for high-stress applications. Grade 304 offers a balance of strength and enhanced corrosion resistance, particularly at elevated temperatures. Grade 316/316L provides the highest level of corrosion resistance among these options, making it ideal for demanding environments, though it comes at a higher cost.

Aluminum

We utilize top aluminum alloys such as 3003, 5052, and 6061 in our stamping processes. These alloys are favored for their exceptional strength-to-weight ratio, outstanding corrosion resistance, and superior thermal and electrical conductivity. These properties make aluminum an ideal choice for stamped components in industries like automotive, medical, and electronics.

Comprehensive Value-Added Services

At Plantmetal, we streamline your project from 'Start to Part' with a holistic solution, eliminating the need for multiple suppliers and reducing your time and costs by up to 50%. Our services encompass the full spectrum of metal stamping, from initial processing through to post-processing. Additionally, we offer supplementary services designed to further enhance the value and efficiency of your project.

- Deburring

- Plating

- Heat Treat

- Welding

- Anodizing

- Riveting

Why Choose Plantmetal for Your Metal Parts Manufacturing?

At Plantmetal, our IATF16949 certification reflects our commitment to the highest standards of quality management, ensuring the reliability and precision of every part we produce. With over 20 years of experience, we've built long-term partnerships with Fortune 500 companies like ABB, Tyco, and Flextronics, consistently being recognized at their quality supplier conferences. Our global presence includes dedicated after-sales service centers in Bulgaria and Mexico, enabling prompt responses and seamless communication, saving our clients valuable time.

Customer Support

Plantmetal offers 24/7 customer support, ensuring that our expert team is always available to address your needs.

Global Service Coverage

We operate on a global scale, with a presence across regions including the USA and Europe.

Expertise

With more than two decades of industry expertise, we deliver superior manufacturing solutions.

Cost Efficiency

We tailor our innovations to meet your specific requirements, developing cost-effective solutions that optimize your production process.