Overview:

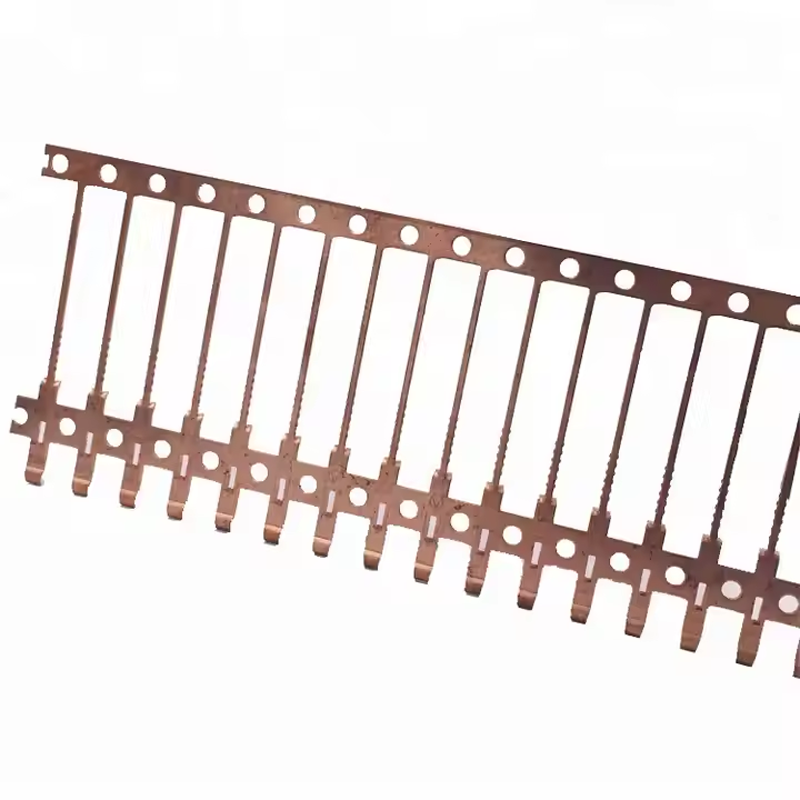

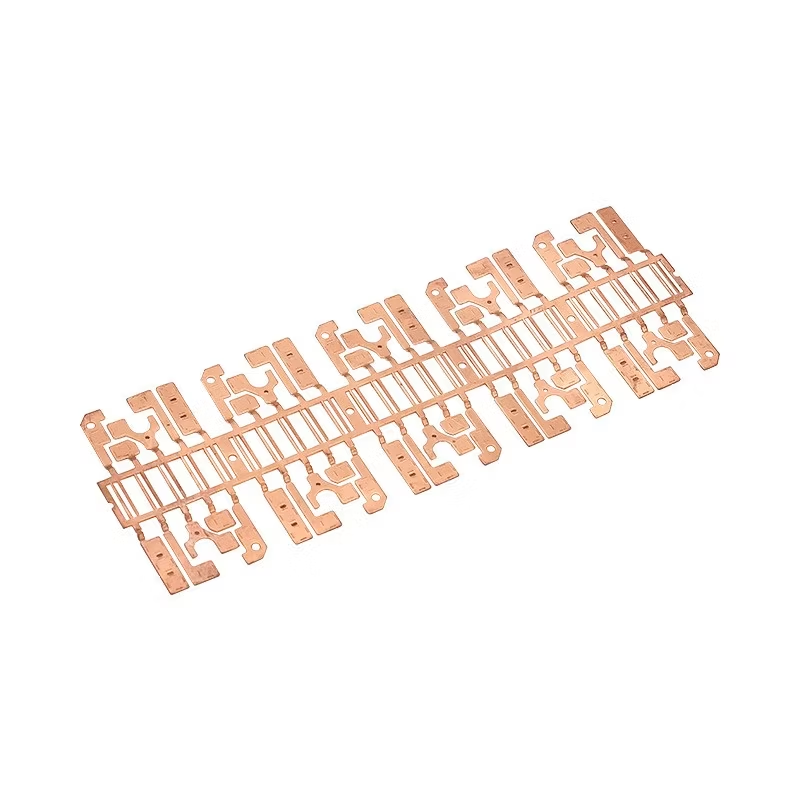

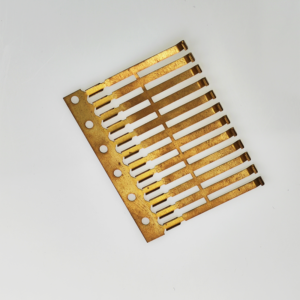

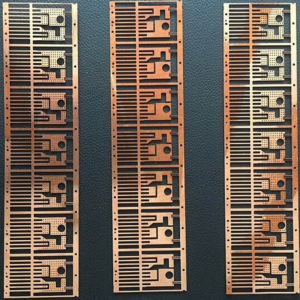

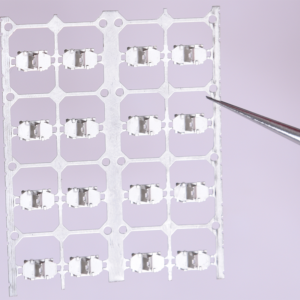

Copper-1100 metal stamped lead frames are precision components used in electronic sensors, offering excellent conductivity and corrosion resistance. Made from high-purity Copper-1100, these lead frames are produced through advanced progressive stamping techniques to ensure precise dimensions and consistent quality.

We provide custom solutions, including material options, custom sizes, and surface treatments like electroplating or nickel plating, tailored to meet specific application needs. Contact us for high-performance, OEM lead frames designed to enhance your electronic sensor applications.

Characteristics:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | Copper |

| Manufacturing Process | Progressive Stamping |

| Size | Custom |

| Application | Electronic Sensors, LED, etc. |

| Surface Treatment | Nickel Plating, Zinc Plating, Tin Plating, Chrome Plating |

| Service | OEM Accepted |

| Color | Custom |

| Tolerance | ±0.03mm |

| Certificates | IATF16949, ISO9001 |

Quality Test Process:

The quality testing process for Copper-1100 Metal Stamped Lead Frames for Electronic Sensors involves several key stages to ensure precise performance and durability. Initially, raw materials, such as Copper-1100, undergo stringent inspections for material composition and purity using advanced equipment like spectrometers and X-ray fluorescence (XRF) analyzers. Once stamping is complete, the lead frames are subjected to dimensional accuracy tests, using high-precision measuring tools such as Coordinate Measuring Machines (CMM) to ensure tight tolerances (±0.03mm).

Further testing includes mechanical property evaluations, where the frames undergo stress and tensile testing to verify strength and elasticity. Surface finish quality is checked with visual inspections and advanced imaging equipment, while corrosion resistance is assessed via salt spray tests. Additionally, automated inspection systems, including 3D scanners and automated vision systems, are used to detect any potential defects in the stamped components. This rigorous process ensures that every lead frame meets the highest standards of reliability and performance before delivery.

Our Advantages

-

Certifications & Compliance

– IATF 16949:2015 & ISO 9001:2015 certified for quality assurance.

-

Custom Solutions

– OEM services with tailored metal stamping parts and precise specifications.

-

Advanced Design & Simulation

– Utilizing AutoForm and VISI CAD/CAM software for optimized design and manufacturing.

-

Competitive Pricing & High Quality

– Factory-direct pricing with high-quality materials and efficient production processes.

Factory Show:

We operate a fully equipped manufacturing facility designed to deliver superior quality metal stamping products. Our plant features 25 high-performance punch presses, ranging from 25 tons to 300 tons, alongside precision wire EDM machines, advanced grinding tools, welding stations, polishing equipment, and ultrasonic cleaning systems.

To further enhance the functionality, durability, and aesthetics of our metal stamped components, we offer a range of advanced metal plating services. These include electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our cutting-edge plating capabilities ensure consistent, high-quality finishes that provide excellent corrosion resistance and adhere to stringent industry standards.

By combining automated production lines, state-of-the-art machinery, robust quality control protocols, and specialized plating processes, we are committed to producing metal stamping products that meet the highest benchmarks of performance, durability, and precision.