Overview:

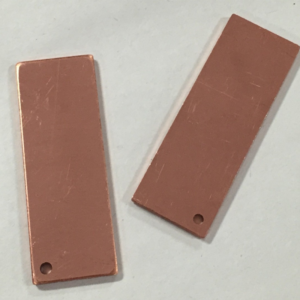

Our custom brass electrical battery spring contacts are precision-engineered using metal stamping for superior quality and performance. Manufactured from high-quality brass and treated for corrosion resistance, these durable contacts are designed for use in electronics, automotive, and solar applications. As a reliable supplier and manufacturer, we offer custom solutions tailored to meet your specifications, ensuring durability and high performance in critical applications.

Features:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | Brass |

| Process | Metal Stamping |

| Origin | Xiamen, China |

| Service | Customized OEM |

| Application | Electronic and electrical products |

| Size | Customized Size |

| Color | Customized Color |

| Certificate | ISO9001, IATF16949 |

Production Process:

- Material Selection: High-quality brass material is selected based on the specific requirements for conductivity, durability, and corrosion resistance.

- Metal Stamping: The brass sheets are fed into stamping presses, where the metal is precisely shaped and cut using custom progressive dies to form the desired contact shapes.

- Forming and Shaping: The stamped brass contacts undergo forming processes such as bending, coiling, or compressing to achieve the final shape necessary for proper electrical connectivity.

- Surface Treatment: The brass contacts are subjected to surface treatments, such as nickel plating or tin coating, to improve corrosion resistance, enhance electrical conductivity, and ensure long-lasting performance.

- Quality Control: Each part is meticulously inspected to ensure it meets strict tolerance and performance standards, using advanced measurement tools and testing methods to verify functionality.

- Assembly (if applicable): If needed, additional components or spring mechanisms are assembled to create the final product, ensuring proper fitting and functionality within battery systems.

- Packaging: The finished brass spring contacts are carefully packaged to prevent damage during transportation and are ready for delivery to customers.

Surface Treatment Options:

– Nickel Plating (Ni-plating): Provides enhanced corrosion resistance, improved durability, and excellent electrical conductivity, ensuring long-lasting performance in various applications.

– Zinc Plating (Zn-plating): Offers a protective layer against corrosion, improving the longevity of the brass contacts in humid or harsh environments.

– Tin Plating: Enhances electrical conductivity while also offering corrosion resistance, making it ideal for battery contacts where reliable electrical connection is crucial.

– Silver Plating: Provides superior conductivity and corrosion resistance, ensuring minimal electrical resistance and maximum reliability in demanding electrical and electronic applications.

Why Choose Us?

-

Cutting-Edge Research and Development

Our skilled R&D team drives constant advancements in manufacturing technologies, focusing on cost reduction, enhanced product functionality, and continuous innovation. This proactive approach enables us to stay at the forefront of industry developments, offering our clients the latest, most effective solutions.

-

In-House Tooling and Die Development

We manage the entire tooling and die creation process internally, ensuring complete control over the precision and quality of each component. This integrated strategy streamlines production, maintaining high standards of efficiency, consistency, and precision across all projects.

-

Strict Quality Control Standards

Our ISO 9001 and IATF 16949 certifications reflect our commitment to the highest quality standards. We rigorously follow quality control procedures to ensure each product meets or exceeds industry requirements, offering unparalleled durability, accuracy, and reliability for high-demand applications.

-

Thorough Product Inspections

We conduct 100% inspections on all finished products, ensuring they meet the specified criteria. Our detailed inspection process guarantees each product’s superior quality, performance, and reliability, meeting exact requirements for its intended application.

-

Guaranteed On-Time Delivery

We ensure timely delivery, even for urgent orders. With optimized production processes and a strong focus on deadlines, we consistently meet our delivery commitments without compromising on quality or performance.

-

Custom Solutions and Services

We specialize in offering custom solutions tailored to meet specific client requirements. Our dedicated team works closely with clients to design and manufacture products that fit precise needs, providing flexibility and customization in every project.