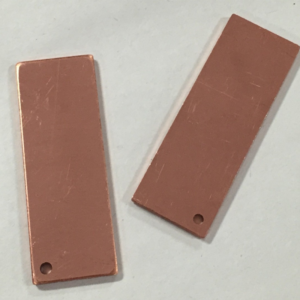

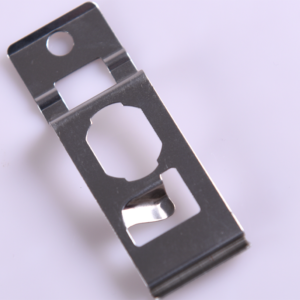

We utilize a range of stamping techniques, including cutting, punching, and bending, combined with precision mold manufacturing to produce parts that meet exact client specifications. Our state-of-the-art stamping equipment and meticulous tooling guarantee high-quality output. The custom metal bracket, crafted from SECC material with a polished surface finish, boasts both aesthetic appeal and structural integrity. This type of bracket is widely applied across various industries, including furniture manufacturing, electronic equipment, and automotive components, offering robust support and enhancing the overall appearance of the products.

Factory Show

We operate a comprehensive range of plants and equipment to ensure the highest quality production. Our facilities are equipped with 25 punch presses ranging from 25 tons to 300 tons, precision wire EDM machines, grinding equipment, welding and polishing tools, and ultrasonic cleaning systems.

In addition to our manufacturing capabilities, we offer a variety of metal plating processes to enhance the durability, appearance, and functionality of our metal stamping products. These include electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our state-of-the-art plating facilities ensure consistent finishes, corrosion resistance, and compliance with industry standards.

This combination of professional and automated production lines, advanced mechanical equipment, rigorous quality control measures, and high-quality plating processes ensures we deliver metal stamping products of the highest standard.

Certification

- ISO 9001:2015 Certification

- IATF 16949 Certification

- First Article Inspection (FAl)

- PPAP Report(Production Part Approval Process)

- Material Technical Data Sheets (TDS)

- CMM Inspection Report

- SPC Report (Statistica Process Control)

- Material Certificates

- Dimensional Inspection Report (CMM)

- DFM feedback