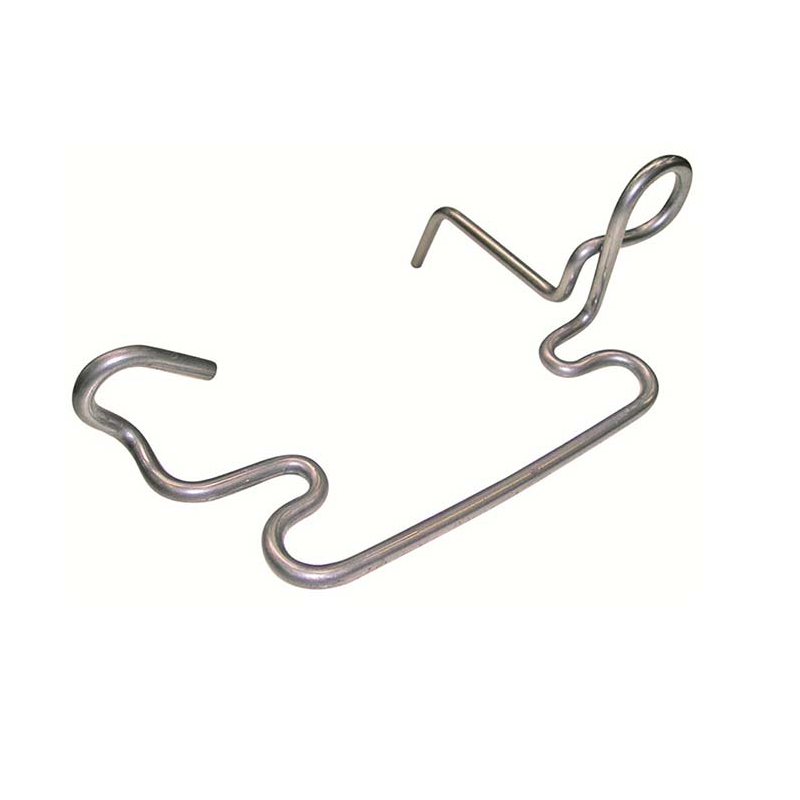

Wire forming reshapes wire materials using techniques like piercing, bending, and shearing, essential in industries such as automotive, food production, and medical equipment. This process handles various metals, including aluminum, brass, and steel. Starting with coiled wire, the material is straightened before further processing with manual or CNC machines. Common wire forms, like springs, clips, and hooks, are customized to meet specific needs. We provide custom wire forming solutions, ensuring top quality for your applications.

Basic Information

Mould: Multi step Progressive Dies

Surface Processing :Electroplating

Fine Blanking: Yes

Multi-Position Process :Yes

Forming Process :Metal Stamping Parts

Tolerances :0.1 mm

Customized: Yes

Processing: Stamping, Machining, Laser Cutting, CNC Bending, Welding

Size :Range Min: 3.0 x 3.0 mm, Max: 1000 x 2000 mm

Dimensions :As per Client’s Requirement

Thickness: 0.4 – 20.0 mm

Drawing Format :DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI, PDF, JPG, DWF

Quality System Certificate :ISO 9001, SGS, BV

Transport Package: Wooden Cases or Carton

Specification: As per Request

Origin: China

Production Capacity :50,000 PCS/Month

One-Stop Service for Metal Stamping Parts

– Design and Prototyping: We provide end-to-end design services, including CAD modeling and prototyping, to ensure your metal stamping parts meet precise specifications and functionality requirements.

– Tooling and Die Development: Our facilities handle the complete tooling and die creation process, utilizing advanced technology to produce high-precision tools and dies that ensure consistent part quality.

– Metal Stamping Production: We offer comprehensive metal stamping services, capable of handling a wide range of materials and sizes. Our equipment supports both high-volume production and custom orders with exceptional accuracy.

– Surface Treatment: Enhance the performance and appearance of your parts with our surface treatment options, such as electroplating, coating, and polishing, tailored to meet your specific requirements.

– Quality Control: Our rigorous quality control process includes thorough inspections and testing to ensure that every part adheres to the highest standards of precision and durability.

– Custom Packaging and Logistics: We provide custom packaging solutions and manage logistics to deliver your stamped parts safely and efficiently, ensuring they arrive on time and in optimal condition.

– Post-Production Support: Our service extends beyond manufacturing, offering ongoing support to address any issues, provide maintenance, and ensure that your needs are continuously met.