Overview

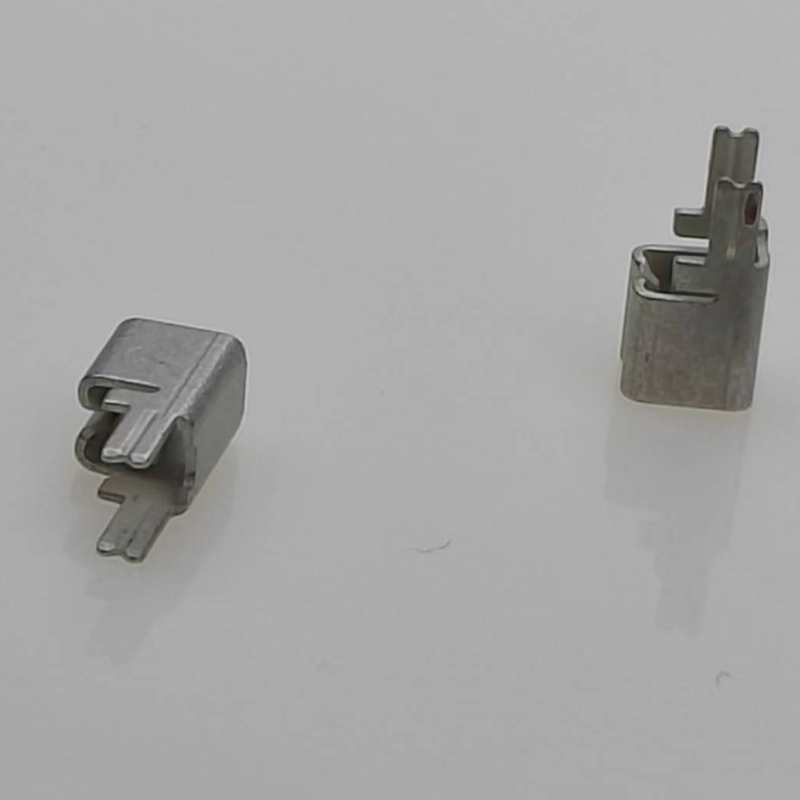

Our wire terminals are designed for reliable and secure electrical connections, ensuring optimal performance in a wide range of applications. Made from high-quality materials like copper and tin, these terminals provide excellent conductivity and resistance to corrosion. Available in various types, including ring, spade, and butt connectors, they are easy to install and provide a strong, durable connection. Perfect for automotive, industrial, and household electrical systems, our wire terminals meet strict quality standards for safety and reliability. Whether you need standard or custom solutions, we deliver high-performance terminals for all your wiring needs.

Basic Information

– Surface Treatment: Electroplating

– Forming Process: Stamping, Crimping

– Surface Finish Options: Nickel Plating, Tin Plating, Zinc Plating

– Sample Availability: Available

– Tolerance: ±0.002 mm

– Size: Customizable as per requirement

– Application: Automotive, Electrical, Industrial, Household, etc.

– Manufacturing Approach: Stamping, Crimping, Welding, Cutting

– Transport Packaging: OPP Bag, Box, or Custom

– Specification: Customized

– Origin: Xiamen, China

One-Stop Service for Metal Stamping Parts

– Design and Prototyping: We provide end-to-end design services, including CAD modeling and prototyping, to ensure your metal stamping parts meet precise specifications and functionality requirements.

– Tooling and Die Development: Our facilities handle the complete tooling and die creation process, utilizing advanced technology to produce high-precision tools and dies that ensure consistent part quality.

– Metal Stamping Production: We offer comprehensive metal stamping services, capable of handling a wide range of materials and sizes. Our equipment supports both high-volume production and custom orders with exceptional accuracy.

– Surface Treatment: Enhance the performance and appearance of your parts with our surface treatment options, such as electroplating, coating, and polishing, tailored to meet your specific requirements.

– Quality Control: Our rigorous quality control process includes thorough inspections and testing to ensure that every part adheres to the highest standards of precision and durability.

– Custom Packaging and Logistics: We provide custom packaging solutions and manage logistics to deliver your stamped parts safely and efficiently, ensuring they arrive on time and in optimal condition.

– Post-Production Support: Our service extends beyond manufacturing, offering ongoing support to address any issues, provide maintenance, and ensure that your needs are continuously met.

Advantages of Our Product

High Quality

We specialize in OEM services for leading brands in metal stamping parts, ensuring superior quality.

Processing Speed

Our team of professionals and advanced machinery enable us to significantly shorten delivery times.

Drawing Acceptance

We accept drawings in all formats and ensure high-precision production according to your specifications.

Technology Innovation

We offer design services and technical support to help solve complex problems and drive innovation.