Overview

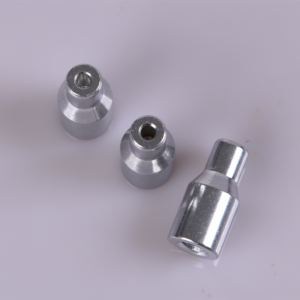

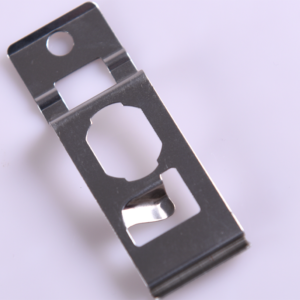

Curtain rod brackets are essential hardware used to securely support curtain rods, ensuring stability and proper alignment for window treatments. Typically made from materials like metal or durable plastic, these brackets come in various styles to suit different rod types and wall surfaces. Many customized options are available, allowing users to select specific sizes, finishes, and designs that match their interior décor and unique requirements. Curtain rod brackets combine functionality with aesthetic appeal, providing both practical support and a polished look for any space.

Basic Information

– Surface Treatment: Electroplating

– Forming Process: Metal Stamping Parts

– Surface Finish Options: Nickel Plating, Sn Plating, Tin Plating, Zinc Plating

– Sample Availability: Available

– Tolerance: ±0.001 mm

– Size: Customizable as per requirement

– Application: Industrial, Furniture, Automotive, Motorcycle, etc.

– Manufacturing Approach: Metal Stamping, Cutting, Punching, Bending, Welding

– Transport Packaging: OPP Bag, Box, or Custom

– Specification: Customized

– Origin: Xiamen, China

Quality Documentation

- ISO 9001:2015 Certification

- IATF 16949 Certification

- First Article Inspection (FAl)

- PPAP Report(Production Part Approval Process)

- Material Technical Data Sheets (TDS)

- CMM Inspection Report

- SPC Report (Statistica Process Control)

- Material Certificates

- Dimensional Inspection Report (CMM)

- DFM feedback

Why Choose Us?

-

Expertise in OEM Parts Production

– Description: Specializing in the production of OEM parts, including metal stamped, machined, deep drawn, and sheet metal formed components. We also offer a range of finishing options to meet diverse requirements.

-

Advanced Machinery and Equipment

– Description: Equipped with a comprehensive range of machinery for punching, welding, CNC, milling, and grinding. Our facility employs reliable equipment and advanced technology to ensure high-quality production.

-

Skilled Workforce and Technical Expertise

– Description: Our team includes experienced technicians dedicated to technical development, skilled workers, professional engineers, and a robust R&D center. We also have an exceptional foreign trade team, all committed to supporting our customers with enthusiasm and expertise.

-

Design-Based Customization

– We offer extensive customization based on your design requirements. Our experienced engineers collaborate closely with you to develop molds that precisely match your specifications, ensuring optimal performance and functionality.

-

Sample-Based Customization

– We provide customization based on sample submissions. This process allows us to replicate and enhance existing designs, ensuring the final product aligns perfectly with your expectations.