Übersicht:

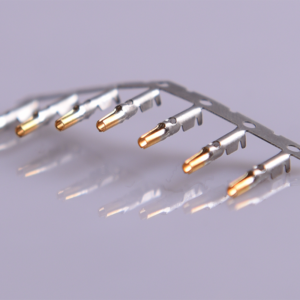

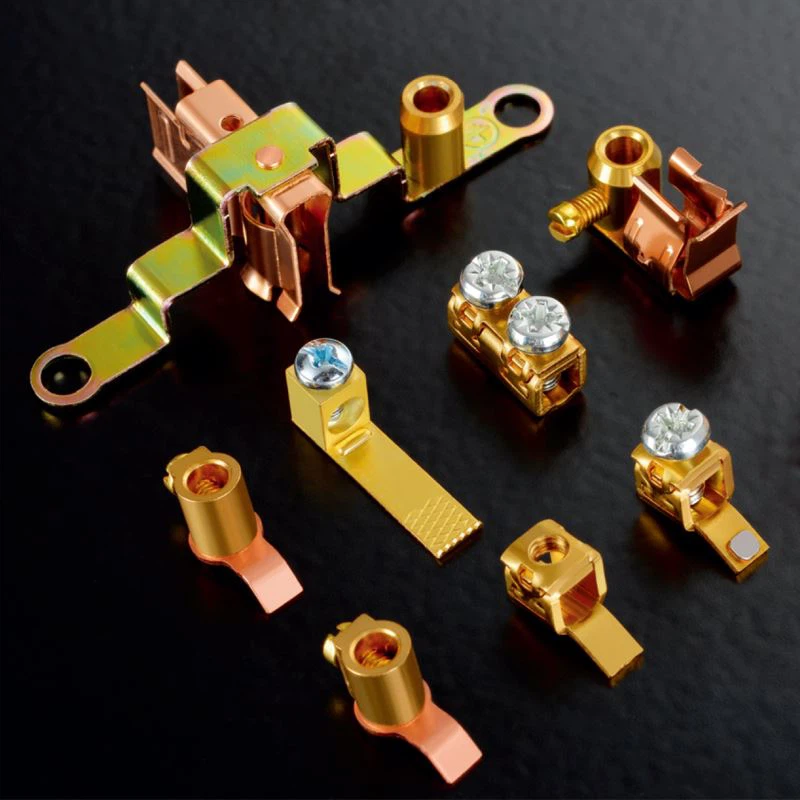

Unsere elektrischen Silberkontaktprodukte werden mit größter Sorgfalt entwickelt und gefertigt, um den höchsten Qualitäts- und Zuverlässigkeitsstandards gerecht zu werden. Dank fortschrittlicher In-Die-Schweißtechnologie gewährleisten wir außergewöhnliche Produktkonsistenz und Stabilität während des gesamten Produktionsprozesses.

Diese elektrischen Kontakte aus Silbermetall bieten nicht nur eine hervorragende Leistung, sondern auch einen signifikanten Kostenvorteil. Durch den Einsatz der In-Die-Schweißtechnologie können wir die Produktion optimieren, was eine Fertigung in großen Stückzahlen ermöglicht, die die Kosten senkt und die Gesamteffizienz der Produktion steigert.

Details:

| Spezifikation | Einzelheiten |

| Craftsmanship | Stanzen, CNC |

| Fertig | Beschichtung (Galvanisieren, Vernickeln usw.) |

| Preis | Echtzeit-Fabrikpreise |

| Verpackung | Inner: Plastiktüte und PE-Schaum; Outer: Kartonverpackung |

| Dienstleistungen | OEM-Dienstleistungen verfügbar für kundenspezifische Designs und Spezifikationen |

| Ursprungsort | Xiamen, China |

| Materialoptionen | Aluminium, Edelstahl, Messing, Kupfer, Kunststoff, usw. |

| Farboptionen | Weiß, Schwarz, Rot, Blau, Silber, Gold, Benutzerdefinierte Farben verfügbar |

| Zertifizierungen | ISO9001:2015, SGS-zertifiziert |

| Produktionskapazität | 5.000 Einheiten pro Tag (pro Maschine) |

| Durchlaufzeit | 7–15 Tage, abhängig von der Bestellgröße und -komplexität |

| Prüfung | 100% Inspektion, Drittanbieterinspektion auf Anfrage |

| Versandoptionen | DHL, FedEx, UPS, TNT, EMS, per Schiff, per Lkw oder per Zug |

Produktionsprozess:

- Materialauswahl: Hochreines Silber und andere Legierungsmaterialien werden sorgfältig ausgewählt, um eine exzellente elektrische Leitfähigkeit, Haltbarkeit und Korrosionsbeständigkeit zu gewährleisten.

- Die Konstruktion und Werkzeugherstellung: Präzise Stanzwerkzeug-Designs werden mithilfe moderner CAD/CAM-Software erstellt, um eine optimale Formgebung der elektrischen Kontaktkomponenten zu gewährleisten. Die Werkzeuge werden anschließend mit hoher Präzision durch CNC-Bearbeitung oder andere fortschrittliche Techniken gefertigt.

- Stanzen und Formen: Die Rohmaterialien werden mit hochpräzisen Stanzmaschinen gestanzt, wodurch die Grundform der elektrischen Kontakte entsteht. Dieser Prozess wird sorgfältig überwacht, um gleichbleibende Maße und Qualität sicherzustellen.

- In-Die-Schweißen: Bei bestimmten Konstruktionen wird die In-Die-Schweißtechnologie verwendet, um Komponenten während des Stanzprozesses zu verbinden. Dies gewährleistet starke, nahtlose Verbindungen und eliminiert den Bedarf an zusätzlichen Montageschritten.

- Oberflächenbehandlung: Die elektrischen Kontakte durchlaufen verschiedene Oberflächenbehandlungen wie Beschichtung, Polieren oder Überziehen, um ihre Haltbarkeit, elektrische Leitfähigkeit sowie ihre Widerstandsfähigkeit gegen Verschleiß und Korrosion zu verbessern.

- Inspektion und Prüfung: Jede Charge von Silber-Metall-Elektrokontakten unterliegt strengen Prüfungen, einschließlich Maßkontrollen, visuellen Inspektionen und elektrischen Leistungstests, um die Einhaltung der Spezifikationen und Industriestandards sicherzustellen.

- Verpackung: Nach der Freigabe werden die elektrischen Kontakte sorgfältig verpackt, um Schäden während des Versands zu vermeiden und sicherzustellen, dass sie in optimalem Zustand ankommen.

- Versand: Das Endprodukt wird anschließend an die Kunden versandt, mit Optionen für beschleunigten oder Standardversand, je nach den Anforderungen des Kunden.

Oberflächenbehandlungsoptionen:

Eloxieren: Bietet eine langlebige, korrosionsbeständige Oberfläche mit erhöhter Härte, ideal für Aluminiumkomponenten.

Pulverbeschichtung: Bietet eine robuste, hochwertige Oberfläche, die Absplittern, Kratzer und Ausbleichen widersteht, erhältlich in einer großen Auswahl an Farben.

Anstrich: Bietet eine glatte, optisch ansprechende Oberfläche mit hervorragender Haftung, ideal für sowohl schützende als auch dekorative Anwendungen.

Sandstrahlen: Erzeugt eine gleichmäßige, matte Textur auf Metalloberflächen, verbessert deren Aussehen und bereitet sie für weitere Veredelungsbehandlungen vor.

Polieren: Erzielt ein hochglänzendes, spiegelähnliches Finish, das die optische Anziehungskraft der Oberfläche verbessert und gleichzeitig eine glatte, verfeinerte Textur bietet.

Fabrikvorführung: