Beschreibung:

Kundenspezifische Stanzteile aus Edelstahl – Präzisionsgefertigte Metallklammern, die durch Stanzen aus hochwertigen Materialien wie Edelstahl, Federstahl und Kohlenstoffstahl hergestellt werden. Diese Klammern werden gefertigt, um spezifische Leistungsanforderungen in verschiedenen Anwendungen zu erfüllen, darunter Automobilindustrie, Luft- und Raumfahrt sowie Industriemaschinen. Wir bieten kundenspezifische Größen und eine breite Palette von Oberflächenbehandlungen wie Verzinken, Brünieren oder Passivieren an, um die Haltbarkeit, Korrosionsbeständigkeit und Gesamtleistung zu verbessern.

Metallstanzklammern können als Klemmen, Befestigungselemente oder Halterungen dienen und durch Druck Gegenstände sicher zusammenhalten. Unsere kundenspezifischen Metallklammern werden in vielen Bereichen eingesetzt, z. B. in Armaturenbrettern, Kotflügelbaugruppen, ABS-Bremssystemen und Steuerschaltern. Mit unserer Expertise in kundenspezifischem Design und Präzisionsfertigung bieten wir Lösungen, die Ihren genauen Spezifikationen entsprechen und eine hohe Qualität und zuverlässige Leistung in anspruchsvollen Umgebungen gewährleisten.

Merkmale:

| Attribut | Einzelheiten |

| Verarbeitungstyp | Metall formen |

| Material | Zink, Aluminium, Kupfer, Stahl, Messing usw. |

| Schimmel | Mehrstufige Folgeverbundwerkzeuge |

| Feinschneiden | Mehrfachposition |

| Prozess | Stanzen, Biegen, Laserschneiden, Schweißen |

| Industrie | Gestanzte Metallteile |

| Toleranzen | ±0,01 mm |

| Angepasst | Verfügbar |

| Dicke | 0,1 mm – 12 mm |

| Zertifizierung | ISO 9001:2015, RoHS |

| Marke | OEM |

| Transportpaket | Plastiktüte/Luftpolsterfolie + Kartons + Holzkiste |

| Spezifikation | OEM |

| Ursprung | China |

Oberflächenoptionen:

-

Galvanisieren

Ein Verfahren, bei dem durch eine elektrochemische Reaktion eine dünne Metallschicht auf die Oberfläche der Klammern abgeschieden wird, wodurch die Korrosionsbeständigkeit und die Haltbarkeit verbessert werden.

-

Sprühbeschichtung

Ein Verfahren, bei dem ein feiner Nebel aus Beschichtungsmaterial auf die Oberfläche der Clips aufgetragen wird, wodurch ein gleichmäßiges Finish erzielt und gleichzeitig der Schutz vor Abnutzung und Umwelteinflüssen verbessert wird.

-

Polieren

Ein mechanisches Veredelungsverfahren, das die Oberfläche der Clips glättet, die Ästhetik verbessert und ein hochglänzendes, edles Aussehen erzeugt.

-

Oxidation

Ein Behandlungsverfahren, das eine kontrollierte Oxidschicht auf der Metalloberfläche erzeugt, wodurch die Korrosionsbeständigkeit verbessert und die Gesamtlanglebigkeit der Clips erhöht wird.

Unsere Vorteile

-

Spezialisierte Expertise in der OEM-Fertigung

Wir sind spezialisiert auf die Herstellung einer breiten Palette von OEM-Komponenten, darunter Metallstanzteile, maschinell bearbeitete Teile, Tiefziehteile und Blechumformteile, mit einer Vielzahl von Oberflächenveredelungen, die auf die Kundenspezifikationen zugeschnitten sind.

-

Strategischer Standortvorteil

Unser Standort in Dongguan, Provinz Guangdong, bietet eine strategisch günstige Nähe zu den wichtigsten Häfen von Shenzhen. Dies ermöglicht uns schnellere und kosteneffizientere Versandlösungen und verbessert gleichzeitig unsere Serviceleistungen für internationale Kunden.

-

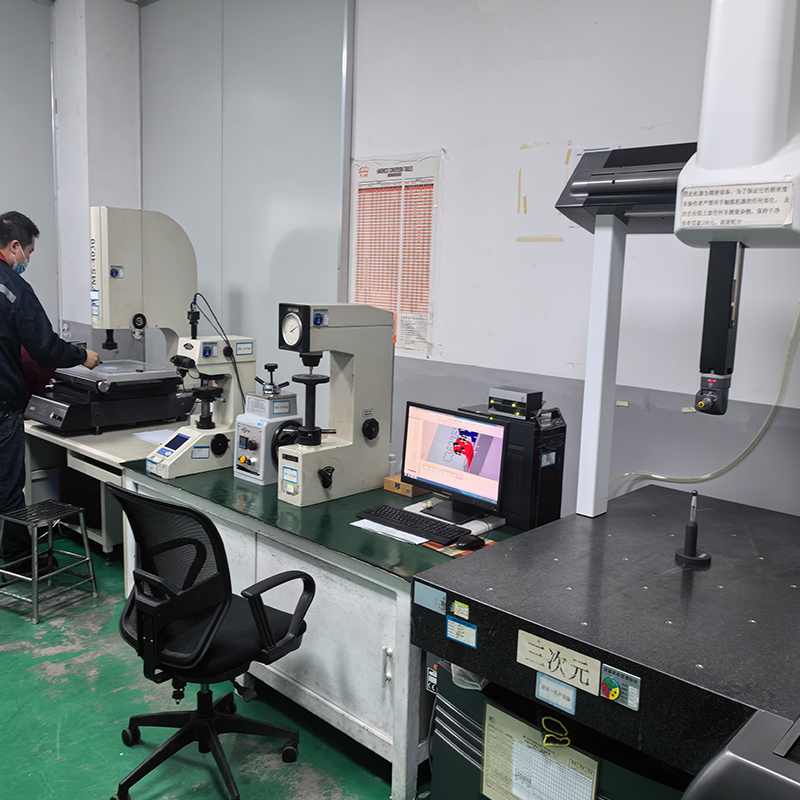

Moderne Maschinen und qualifizierte Arbeitskräfte

Ausgestattet mit modernsten Maschinen zum Stanzen, Schweißen, CNC-Bearbeiten, Fräsen und Schleifen gewährleisten wir Präzision und Zuverlässigkeit in jeder Produktionsphase. Unsere qualifizierten Mitarbeiter bedienen diese fortschrittlichen Systeme mit größter Sorgfalt und Liebe zum Detail.

-

Engagierte technische Expertise und Support

Unser Team besteht aus erfahrenen Technikern, die sich auf kontinuierliche technische Weiterentwicklung konzentrieren, um sicherzustellen, dass wir an der Spitze der Fertigungsinnovation bleiben. Unterstützt von einem engagierten Team aus professionellen Ingenieuren und Außenhandelsspezialisten, sind wir bestrebt, unseren Kunden außergewöhnlichen Support und Service zu bieten.

Fabrikvorführung:

Wir betreiben eine umfassende Auswahl an Anlagen und Ausrüstung, um eine Produktion von höchster Qualität sicherzustellen. Unsere Einrichtungen sind mit 25 Stanzpressen ausgestattet, die von 25 Tonnen bis 300 Tonnen reichen, präzisen Drahterodiermaschinen (Wire EDM), Schleifgeräten, Schweiß- und Polierwerkzeugen sowie Ultraschallreinigungssystemen.

Zusätzlich zu unseren Fertigungskapazitäten bieten wir eine Vielzahl von Metallbeschichtungsverfahren an, um die Haltbarkeit, das Erscheinungsbild und die Funktionalität unserer Metallprägeprodukte zu verbessern. Dazu gehören Galvanisierung, Zinkbeschichtung, Nickelbeschichtung, Chrombeschichtung und Anodisierung. Unsere hochmodernen Beschichtungsanlagen gewährleisten gleichmäßige Oberflächen, Korrosionsbeständigkeit und die Einhaltung von Industriestandards.

Diese Kombination aus professionellen und automatisierten Produktionslinien, fortschrittlicher mechanischer Ausrüstung, strengen Qualitätskontrollmaßnahmen und hochwertigen Beschichtungsverfahren gewährleistet, dass wir Metallstanzprodukte von höchstem Standard liefern.