Übersicht:

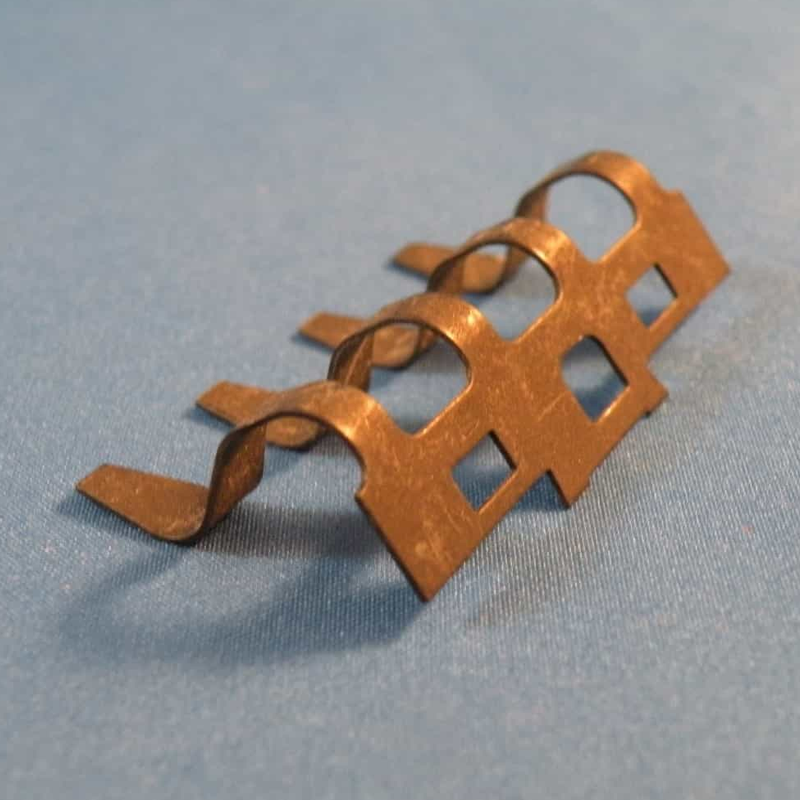

Vergoldete Metallstanzverbindungselemente sind präzisionsgefertigte Komponenten, die mithilfe fortschrittlicher Metallstanzverfahren hergestellt und anschließend mit einer hochwertigen Vergoldung versehen werden. Diese Vergoldung verbessert nicht nur die Ästhetik, sondern auch die Korrosionsbeständigkeit und Haltbarkeit. Als führender Lieferant und Hersteller sind wir auf kundenspezifische Lösungen spezialisiert und bieten umfassende Dienstleistungen für diese Verbindungselemente an. In der Haushaltsgeräteindustrie bieten vergoldete Metallstanzverbindungselemente einen Wettbewerbsvorteil, indem sie zuverlässige Leistung, verbesserte Langlebigkeit und eine ansprechende Optik in Produkten wie Kühlschränken, Waschmaschinen und Mikrowellenherden gewährleisten. Unsere kundenspezifischen Möglichkeiten ermöglichen maßgeschneiderte Designs, die den spezifischen Anforderungen jedes Geräts gerecht werden und außergewöhnliche Funktionalität und Wertschöpfung bieten.

Details:

| Spezifikation | Einzelheiten |

| Ursprungsort | Xiamen, China |

| Markenname | OEM |

| Größe | Benutzerdefiniert |

| Anwendung | Haushaltsgeräteindustrie |

| Zertifikat | ISO 9001/IATF 16949 |

| Prozess | Metallstanzen |

| Farbe | Benutzerdefiniert |

| Dicke | 0,1–12,0 mm (je nach Bedarf) |

| Form | OEM-Blechstanzen und -Biegen |

| Material | Messing, Kupfer, Kohlenstoffstahl, Edelstahl |

| Inspektion | 100%ige Prüfung vor Auslieferung |

Produktionsprozess:

- Werkstoffwahl: Hochwertige Metalle wie Messing, Kupfer, Kohlenstoffstahl oder Edelstahl werden basierend auf den spezifischen Anwendungsanforderungen hinsichtlich Haltbarkeit und Leistung ausgewählt.

- Metallstanzen: Das ausgewählte Material wird in eine Stanzpresse eingeführt, wo es mithilfe von Präzisionswerkzeugen geschnitten, gebogen und in die gewünschte Verbindungselementform gebracht wird. Dieser Prozess gewährleistet eine hohe Genauigkeit und Konsistenz jedes einzelnen Teils.

- Beschichtungsprozess: Nach dem Metallstanzen werden die Verbindungselemente einem Beschichtungsprozess unterzogen. Die Verbindungselemente werden mit einer Schicht Nickel oder Chrom-Gold beschichtet, um ihre Ästhetik, Korrosionsbeständigkeit und Haltbarkeit zu verbessern.

- Endbearbeitung und Prüfung: Nach der Beschichtung werden die Verbindungselemente sorgfältig geprüft, um sicherzustellen, dass sie strenge Qualitätsstandards erfüllen. Dieser Schritt beinhaltet eine 100%-Kontrolle zur Überprüfung der Abmessungen, der Beschichtungsqualität und der Funktionalität.

- Verpackung und Versand: Nach bestandener Qualitätsprüfung werden die Verbindungselemente verpackt und für den Versand an unsere Kunden vorbereitet. Dabei wird sichergestellt, dass sie sicher gelagert und für den Einsatz in der Haushaltsgeräteindustrie bereit sind.

Oberflächenbehandlungsoptionen:

Versilberung: Eine hochwertige Beschichtung, die die elektrische Leitfähigkeit, die Korrosionsbeständigkeit und die Ästhetik verbessert und häufig in Hochleistungsanwendungen eingesetzt wird, die eine zuverlässige Leitfähigkeit erfordern.

– Vernickelung: Bietet hervorragenden Korrosionsschutz, Härte und Verschleißfestigkeit. Die Vernickelung wird häufig für Komponenten verwendet, die in rauen Umgebungen Strapazierfähigkeit und Schutz benötigen.

– Verzinnung: Bietet hervorragenden Korrosionsschutz, insbesondere für Komponenten, die Feuchtigkeit ausgesetzt sind. Sie wird häufig für elektrische Steckverbinder und Teile verwendet, die lötbar sein müssen.

Säurepassivierung: Ein Verfahren, das die Korrosionsbeständigkeit von Edelstahl durch die Bildung einer schützenden Oxidschicht erhöht. Es ist besonders wirksam bei der Verhinderung von Rost und Oxidation und gewährleistet so eine lange Lebensdauer von Metallteilen.

Warum uns wählen?

Maßgeschneiderte OEM-Lösungen & Umfassende Montageservices

Mit über zwei Jahrzehnten Branchenerfahrung sind wir auf maßgeschneiderte OEM-Lösungen und umfassende Montageservices spezialisiert. Unsere hochmodernen Fertigungsmöglichkeiten ermöglichen es uns, Ihre genauen Spezifikationen zu erfüllen und so überragende Qualität und Leistung in jedem Produkt zu gewährleisten, das wir liefern.

Vielfältiges Produktangebot

Wir bieten eine umfassende Produktpalette, darunter präzisionsgeprägte Komponenten, CNC-gefertigte Teile, Federn, Wellen, Verbindungselemente und vieles mehr. Als vertrauenswürdiger Full-Service-Partner optimieren wir die Prozesse, um jede Phase Ihres Projekts – vom ersten Entwurf bis zur endgültigen Produktion – zu verwalten und dabei Effizienz und Exzellenz in jedem Schritt zu gewährleisten.

Branchenzertifizierungen & Nachweisliche Expertise

Als zuverlässiger Tier-2-Zulieferer haben wir strenge Fabrikaudits erfolgreich bestanden und verfügen über wichtige Branchenzertifizierungen, darunter RoHS und HE-Konformität. Diese Zertifizierungen bestätigen, dass unsere Produkte den höchsten internationalen Qualitätsstandards entsprechen und alle notwendigen regulatorischen Anforderungen erfüllen.

Kompromissloses Qualitätsstreben

Unsere Zertifizierungen nach ISO 9001:2015 und IATF 16949 spiegeln unser Engagement für Qualitätsmanagementsysteme wider. Diese Zertifizierungen gewährleisten, dass jedes von uns gefertigte Teil mit höchster Präzision und Langlebigkeit produziert wird und eine gleichbleibende Qualität in jeder Produktionsphase gewährleistet ist.