Beschreibung:

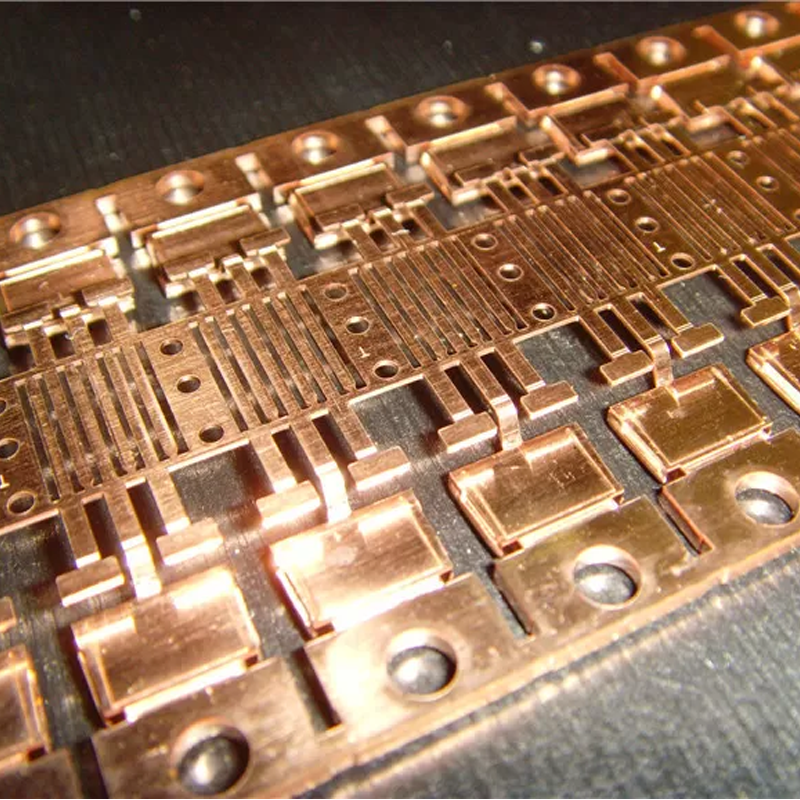

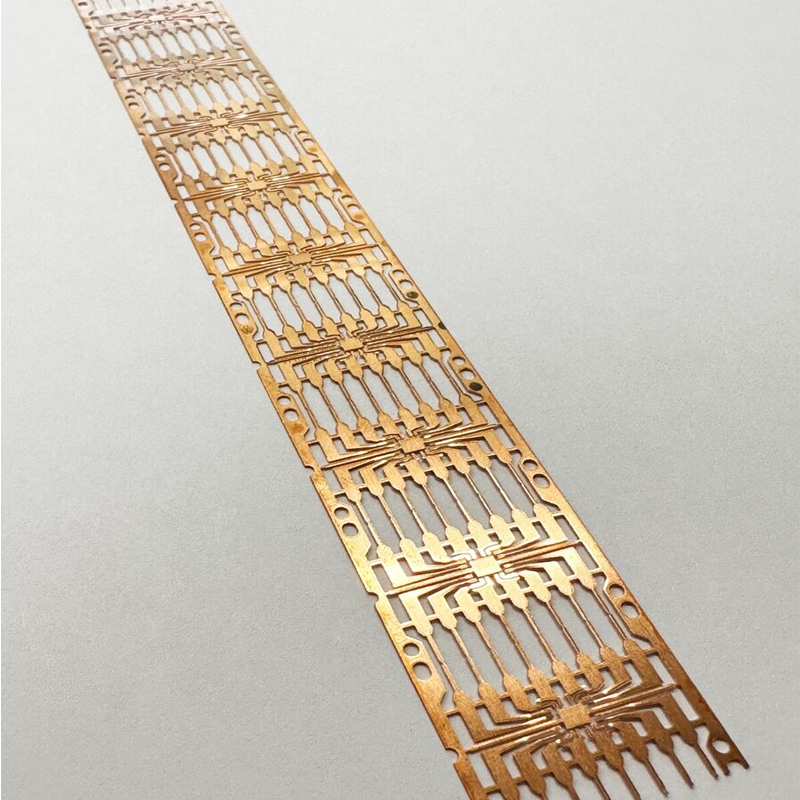

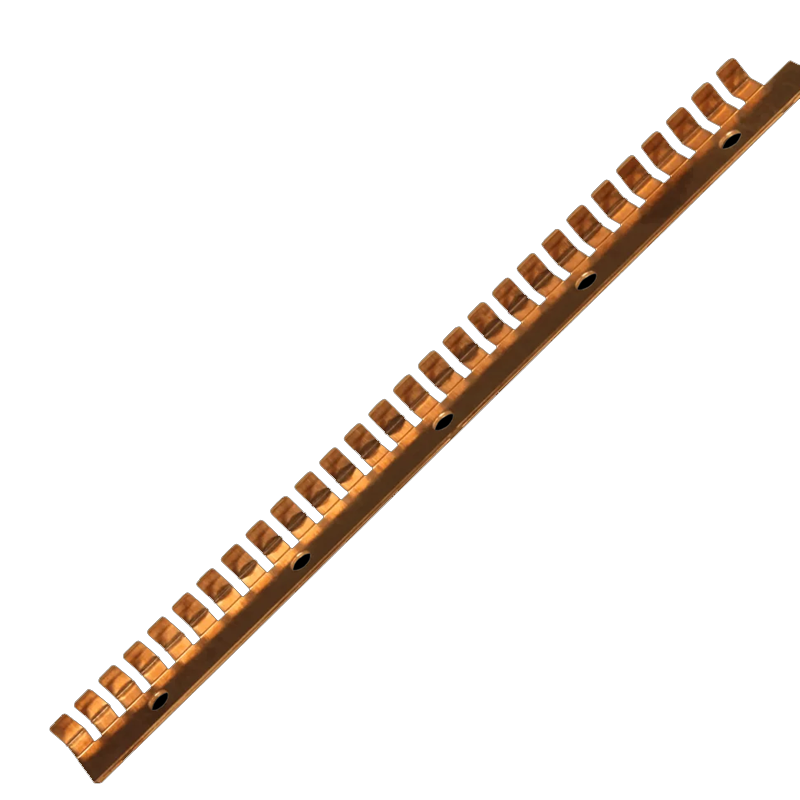

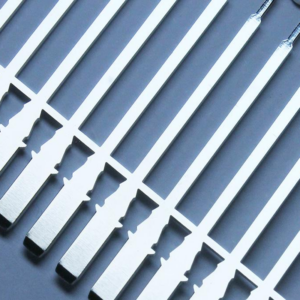

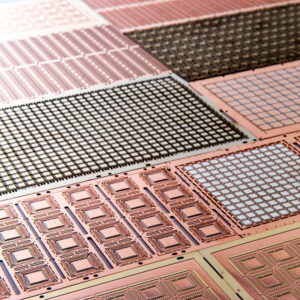

Wir sind spezialisiert auf die Präzisionsfertigung von Kupfer-Leadframes mithilfe modernster Vier- und Mehrschieber- sowie Stanztechnologie. Unser fortschrittlicher Maschinenpark gewährleistet höchste Genauigkeit und Effizienz und ermöglicht es uns, Leadframes zu produzieren, die exakt Ihren Spezifikationen entsprechen. Mit einem starken Fokus auf handwerkliches Können und Prozesskontrolle arbeiten wir eng mit unseren Kunden zusammen, um sicherzustellen, dass jede Designanforderung präzise umgesetzt wird.

Unser Werk ist nach ISO 9001, ISO 14001 und IATF 16949 zertifiziert, was unser Engagement für die Einhaltung außergewöhnlicher Qualitätsstandards in allen Produktionsphasen unterstreicht. Vom ersten Entwurf bis zur Endkontrolle implementieren wir strenge Datenerfassungs- und Qualitätssicherungsprotokolle, um sicherzustellen, dass jeder von uns gelieferte Kupfer-Leadframe die höchsten Industriestandards in Bezug auf Leistung und Zuverlässigkeit erfüllt.

Merkmale:

| Attribut | Einzelheiten |

| Ursprungsort | Xiamen, China |

| Markenname | OEM |

| Anwendung | Telekommunikation |

| Material | Kupfer |

| Technik | Metallstanzen |

| Serienfertigungsvorlaufzeit | 10 Tage |

| Beschichtung | Verzinken |

| Paket | Werkspaket oder individuelles Paket |

| Zertifikate | ROHS, ISO |

Produktionsprozess:

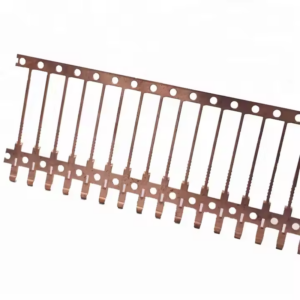

- Materialauswahl: Der Prozess beginnt mit der Auswahl von hochwertigem Kupfer, das aufgrund seiner hervorragenden elektrischen Leitfähigkeit und Eignung für Leadframe-Anwendungen ausgewählt wird. Wir legen Wert auf Materialien, die optimale Leistung in anspruchsvollen Umgebungen gewährleisten.

- Progressivstanzen: Unter Verwendung fortschrittlicher Folgeverbundwerkzeug-Technologie werden Kupfer-Leadframes in mehreren Stufen präzise geformt. Dieses Verfahren gewährleistet eine exakte Formgebung und ermöglicht die Herstellung komplexer Geometrien und feiner Details, wobei die Einheitlichkeit während des gesamten Produktionsprozesses erhalten bleibt.

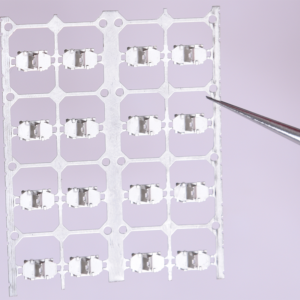

- Trennen und Formen: Nach dem Stanzprozess wird der Leadframe präzise geschnitten und geformt. Dieser Schritt verfeinert das Bauteil, um die erforderlichen Abmessungen und Spezifikationen zu erfüllen und einen exakten Sitz für die Montage und Integration zu gewährleisten.

- Oberflächenbehandlung: Um die Leistung und Haltbarkeit zu verbessern, werden die Leiterrahmen Oberflächenbehandlungen wie Galvanisierung (Zink, Nickel, Zinn) oder Pulverbeschichtung unterzogen. Diese Oberflächenveredelungen bieten nicht nur einen hervorragenden Korrosionsschutz, sondern verbessern auch die Ästhetik und Langlebigkeit der Komponenten.

- Prüfung und Qualitätskontrolle: Umfassende Qualitätskontrollmaßnahmen werden in jeder Phase des Produktionsprozesses durchgeführt. Dazu gehören visuelle Inspektionen, Dimensionsmessungen und Funktionsprüfungen, um sicherzustellen, dass jeder Kupfer-Leadframe den strengen Industriestandards für Qualität und Leistung entspricht.

- Verpackung: Nach der Fertigstellung werden die Kupfer-Leadframes sorgfältig verpackt, um jegliche Beschädigung während des Transports zu vermeiden. Jede Bestellung wird sicher verpackt und für eine schnelle Lieferung vorbereitet, um sicherzustellen, dass das Produkt unsere Kunden in einwandfreiem Zustand erreicht.

Oberflächenbehandlungen:

Präzisionspolieren: Wir verwenden fortschrittliche Poliertechniken, um eine makellose, glatte Oberfläche mit hohem Reflexionsgrad zu erzielen, die optimale Ästhetik und Leistung gewährleistet.

Beschichtungslösungen: Unsere Kupfer-Leadframes können mit einer Vielzahl von Materialien beschichtet werden, darunter Zink, Nickel, Silber und Zinn. Diese Beschichtungsoptionen bieten erhöhte Korrosionsbeständigkeit, verbesserte Haltbarkeit und optimierte elektrische Leitfähigkeit, wodurch sie ideal für anspruchsvolle Anwendungen geeignet sind.

– Pulverbeschichtung: Für einen hervorragenden Schutz vor Umwelteinflüssen bieten wir eine hochleistungsfähige Pulverbeschichtung an. Diese Behandlung erzeugt eine widerstandsfähige, langlebige Oberfläche, die sowohl die mechanischen Eigenschaften als auch die Optik des Leadframes verbessert.

Schwarzoxidierung: Das Schwarzoxidierverfahren erzeugt eine elegante, matte Oberfläche und erhöht die Verschleißfestigkeit deutlich. Diese Behandlung eignet sich besonders für Anwendungen, bei denen sowohl ästhetische Ansprüche als auch funktionelle Haltbarkeit gefragt sind, da sie einen verbesserten Schutz unter rauen Bedingungen bietet.

Fabrikvorführung:

Unsere Anlage ist mit einer breiten Palette modernster Ausrüstung ausgestattet, darunter 25 Stanzpressen (25 bis 300 Tonnen), Drahterodiermaschinen, Schleifwerkzeuge, Schweiß- und Poliersysteme sowie Ultraschallreinigung. Wir bieten auch verschiedene Metallbeschichtungsverfahren wie Galvanisieren, Verzinken, Vernickeln, Verchromen und Eloxieren an, um Haltbarkeit, Aussehen und Funktionalität zu verbessern. Diese Kombination aus modernsten Fertigungsmöglichkeiten, strenger Qualitätskontrolle und hochwertiger Beschichtung gewährleistet die Herstellung erstklassiger Metallstanzteile, die den Industriestandards entsprechen.

Qualitätssicherung:

In unserer Einrichtung legen wir in jeder Produktionsphase großen Wert auf Qualität. Jedes Projekt beginnt mit einer umfassenden Machbarkeitsstudie und einer Run-at-Rate-Analyse, um sicherzustellen, dass die Qualität bereits vor Beginn der Serienfertigung gewährleistet ist. Unser robustes Qualitätsmanagementsystem integriert modernste Technologien, kontinuierliche Prozessverbesserungen und ein engagiertes Qualitätssicherungsteam, um die höchsten Standards zu gewährleisten.

Um Null-Fehler zu gewährleisten, setzen wir sowohl Inline- als auch Offline-Bildverarbeitungssysteme zusammen mit fortschrittlichen Sensortechnologien ein, um Teileigenschaften und -abmessungen während der Produktion sorgfältig zu überwachen.

Wir engagieren uns für die Bereitstellung maßgeschneiderter Lösungen und sind spezialisiert auf kundenspezifische Designs, die die Leistung von Leadframes optimieren. Mit jahrelanger Erfahrung ist Topmetalstamping der ideale Partner für Ihre Anforderungen an die präzise Herstellung von Leadframes.