Diese Metall-Schraubklemmen sind langlebige und vielseitige Befestigungslösungen, ideal für eine breite Palette von Anwendungen. Hergestellt aus hochwertigem Metall, bieten sie sicheren und zuverlässigen Halt und gewährleisten eine lang anhaltende Leistung. Die Schrauben lassen sich leicht anziehen und bieten einen festen Griff sowohl für leichte als auch für schwere Projekte. Perfekt für den Einsatz im Bauwesen, in der Automobilindustrie und im Heimwerkerbereich, bieten diese Klemmen Stärke und Stabilität in verschiedenen Umgebungen. Die Klemmen werden in einer zuverlässigen Produktionsstätte mit Präzision gefertigt und jede einzelne durchläuft eine strenge Qualitätskontrolle, um den Industriestandards für Haltbarkeit und Sicherheit zu entsprechen.

Información Básica

Tratamiento de Superficie: Galvanoplastia

Proceso de Formación: Piezas de estampación metálica

Opciones de Acabado Superficial: Revestimiento de Níquel, Revestimiento de Estaño, Revestimiento de Hojalata, Revestimiento de Zinc

Disponibilidad de muestra: Disponible

Tolerancia: ±0,001 mm

Tamaño: Personalizable según los requisitos

Aplicación: Industrial, Mobiliario, Automoción, Motocicletas, etc.

Enfoque de Fabricación: Estampado de Metal, Corte, Punzonado, Doblado, Soldadura

Embalaje de Transporte: Bolsa OPP, Caja o Personalizado

Especificación: Personalizado

Origen: Xiamen, China

Warum uns wählen?

-

Fachkenntnisse in der Herstellung von OEM-Teilen

Beschreibung: Wir sind spezialisiert auf die Herstellung von OEM-Teilen, darunter gestanzte, bearbeitete, tiefgezogene und aus Blech geformte Komponenten. Darüber hinaus bieten wir eine Vielzahl von Veredelungsoptionen, um unterschiedliche Anforderungen zu erfüllen.

-

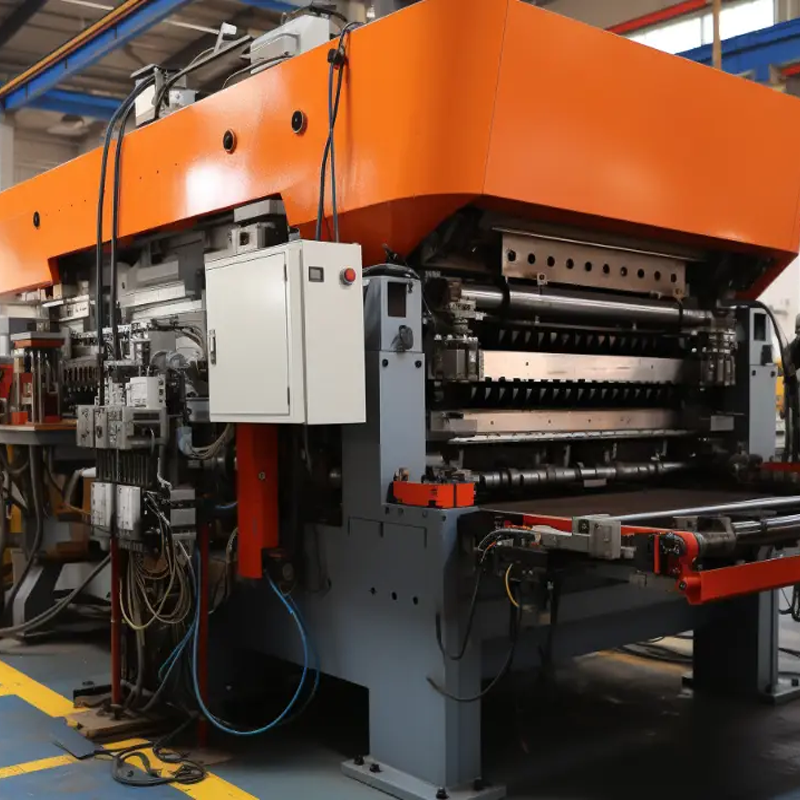

Fortschrittliche Maschinen und Ausrüstung

Beschreibung: Ausgestattet mit einer umfassenden Auswahl an Maschinen für Stanzen, Schweißen, CNC, Fräsen und Schleifen. Unsere Einrichtung nutzt zuverlässige Ausrüstung und fortschrittliche Technologie, um eine hochwertige Produktion sicherzustellen.

-

Fachkräfte und technisches Fachwissen

Beschreibung: Unser Team besteht aus erfahrenen Technikern, die sich der technischen Entwicklung widmen, qualifizierten Facharbeitern, professionellen Ingenieuren und einem starken F&E-Zentrum. Darüber hinaus verfügen wir über ein herausragendes Außenhandelsteam, das mit Begeisterung und Fachwissen daran arbeitet, unsere Kunden bestmöglich zu unterstützen.

-

Designbasierte Anpassung

Wir bieten umfassende Anpassungen basierend auf Ihren Designanforderungen an. Unsere erfahrenen Ingenieure arbeiten eng mit Ihnen zusammen, um Formen zu entwickeln, die genau Ihren Spezifikationen entsprechen und optimale Leistung sowie Funktionalität gewährleisten.

-

Probenbasierte Anpassung

Wir bieten Anpassungen basierend auf Musterzusendungen an. Dieser Prozess ermöglicht es uns, bestehende Designs nachzubilden und zu verbessern, sodass das Endprodukt perfekt Ihren Erwartungen entspricht.

Qualitätsdokumentation

- ISO 9001:2015-Zertifizierung

- IATF 16949-Zertifizierung

- Erststückprüfung (FSP)

- PPAP-Bericht (Produktionsfreigabeprozess)

- Technische Datenblätter für Materialien (TDS)

- CMM-Prüfbericht

- SPC-Bericht (Statistische Prozesskontrolle)

- Materialzertifikate

- Maßprüfbericht (KMG)

- DFM-Feedback