Übersicht:

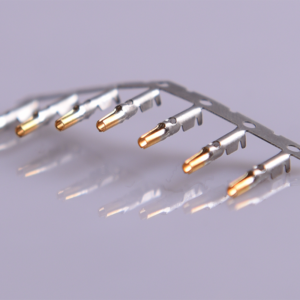

Elektrische Steckverbinder für Batterieausrüstungen, auch als Crimpklemmen oder Crimpverbinder bezeichnet, spielen eine entscheidende Rolle bei der Verbindung von Drähten und Kabeln mit Komponenten innerhalb eines elektrischen Systems. Diese Steckverbinder sind ein integraler Bestandteil der Funktionalität von batteriebetriebenen Systemen in verschiedenen Anwendungen, einschließlich Fahrzeugen, Haushaltsgeräten, Schalttafeln und anderen elektrischen Installationen.

Zuverlässige Verbindungen sind entscheidend, um die Sicherheit und Effizienz von batteriebetriebenen Geräten zu gewährleisten. Eine schwache oder fehlerhafte Verbindung im elektrischen System kann zu Leistungsproblemen, durchgebrannten Sicherungen oder einem vollständigen Systemausfall führen.

Mit unseren hochwertigen elektrischen Steckverbindern können Sie langlebige und zuverlässige Verbindungen für Ihre Batterieausrüstung erreichen. Als führender Anbieter von präzisionsgestanzten Metallteilen und Baugruppen unterstützen wir vielfältige Branchen mit Lösungen, die darauf ausgelegt sind, die höchsten Anforderungen an Leistung und Zuverlässigkeit zu erfüllen.

Details:

| Kategorie | Einzelheiten |

| Vorteile | Hochtemperaturbeständigkeit |

| Produktionsprozess | Metallstanzen |

| Form | Benutzerdefiniert |

| Zertifizierung | ISO 9001, IATF 16949 |

| Marke | OEM |

| Verfügbares Material | Kupfer, Edelstahl, Kohlenstoffstahl, Aluminium usw. |

| Verwendung | Automotive, Landwirtschaft, Möbel, Maschinen |

| Pressemöglichkeiten | 16 Tonnen – 300 Tonnen |

| Stanzkapazität | Tiefziehen, Metallumformung |

| Stanzwerkzeug | Hausinterne Werkzeugherstellung |

| Proben | Kostenlos verfügbar |

| Dienstleistung | OEM |

| Dateiformat | CAD, SolidWorks, PDF usw. |

| Transportpaket | Wie von Ihnen gewünscht |

| Marke | OEM |

| Ursprung | Xiamen |

Produktionsprozess:

- Forschung & Qualitätsengineering: Anfangsphase mit detaillierter Analyse und Gestaltung, um funktionale und qualitative Spezifikationen zu erfüllen.

- Werkzeugentwicklung: Präzisionsfertigung von Formen und Werkzeugen, um höchste Standards für die Massenproduktion zu erreichen.

- Musterfreigabe: Herstellung von Prototypen für Tests und Validierung, um sicherzustellen, dass alle Spezifikationen erfüllt sind, bevor die Produktion hochskaliert wird.

- Musterfreigabe: Herstellung von Prototypen zur Prüfung und Validierung, um sicherzustellen, dass alle Spezifikationen erfüllt sind, bevor die Produktion hochskaliert wird.

- Qualitätskontrolle Inspektion: Umfassende Bewertung in jeder Phase, um sicherzustellen, dass alle Produkte strengen Qualitäts- und Leistungsstandards entsprechen.

- Verpackung: Sichere und effiziente Verpackung, die darauf ausgelegt ist, Produkte während des Transports und der Lieferung zu schützen.

Oberflächenbehandlungen für elektrische Steckverbinder:

- Beschichtung: Eine Metallschicht wird auf die Oberfläche des Steckverbinders aufgebracht, um die Leitfähigkeit, Korrosionsbeständigkeit und Haltbarkeit zu verbessern. Häufige Beschichtungen umfassen Gold, Zinn oder Nickel.

- Pulverbeschichtung: Eine langlebige, ungiftige Beschichtung, die auf Steckverbinder aufgetragen wird, um die Widerstandsfähigkeit gegen Abnutzung, Witterungseinflüsse und chemische Einwirkungen zu verbessern und gleichzeitig eine glatte, ästhetische Oberfläche zu bieten.

- Eloxieren: Ein Verfahren, das die Dicke der natürlichen Oxidschicht auf Aluminium erhöht, die Korrosionsbeständigkeit verbessert und eine langlebige, korrosionsfreie Oberfläche bietet.

- Anstrich: Schutz- und Dekorlackbeschichtungen, die Widerstandsfähigkeit gegen Umwelteinflüsse bieten und das Erscheinungsbild von Verbindern verbessern.

- Elektrophorese: Ein Beschichtungsverfahren, das ein elektrisches Feld nutzt, um eine gleichmäßige Farbschicht auf Steckverbindern aufzutragen und so hervorragenden Schutz vor Korrosion und Verschleiß bietet.

- Polieren: Ein Endbearbeitungsprozess, der die Oberfläche des Steckverbinders glättet, wodurch sowohl die ästhetische Erscheinung als auch die elektrische Leistung verbessert werden, indem der Widerstand reduziert wird.

Über uns: