Übersicht:

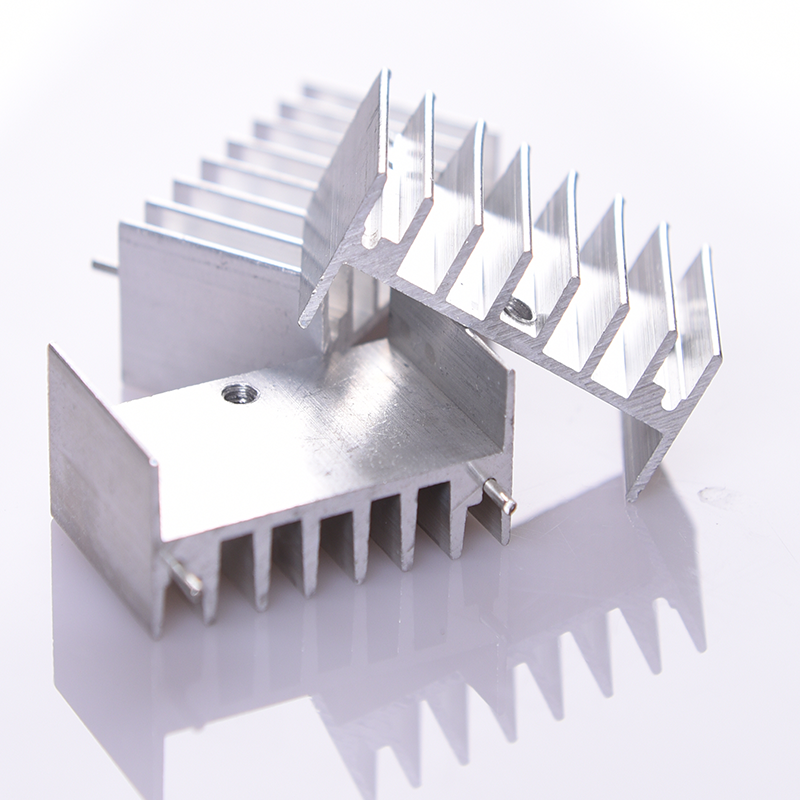

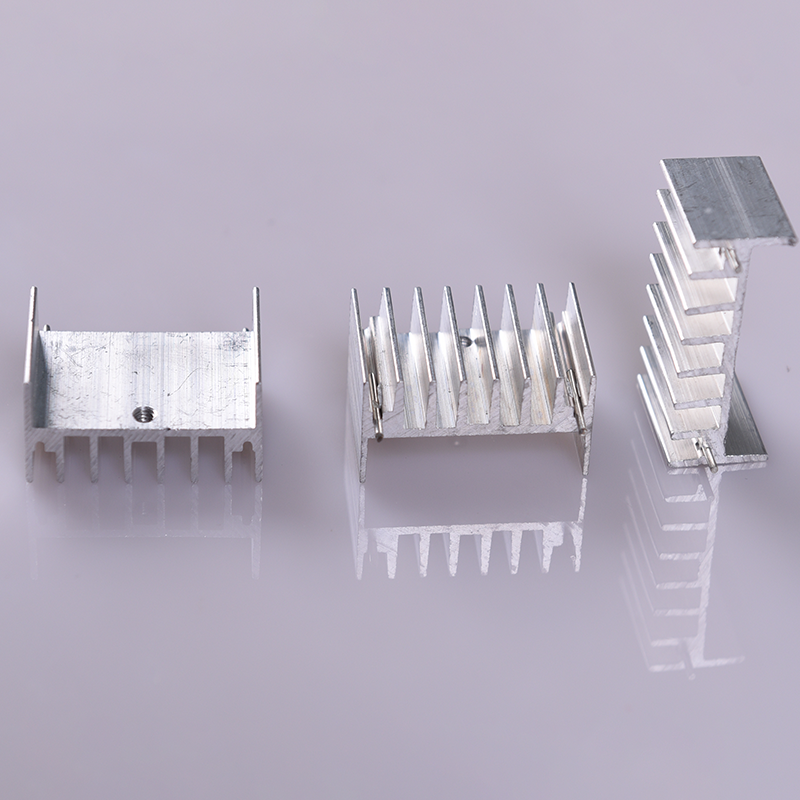

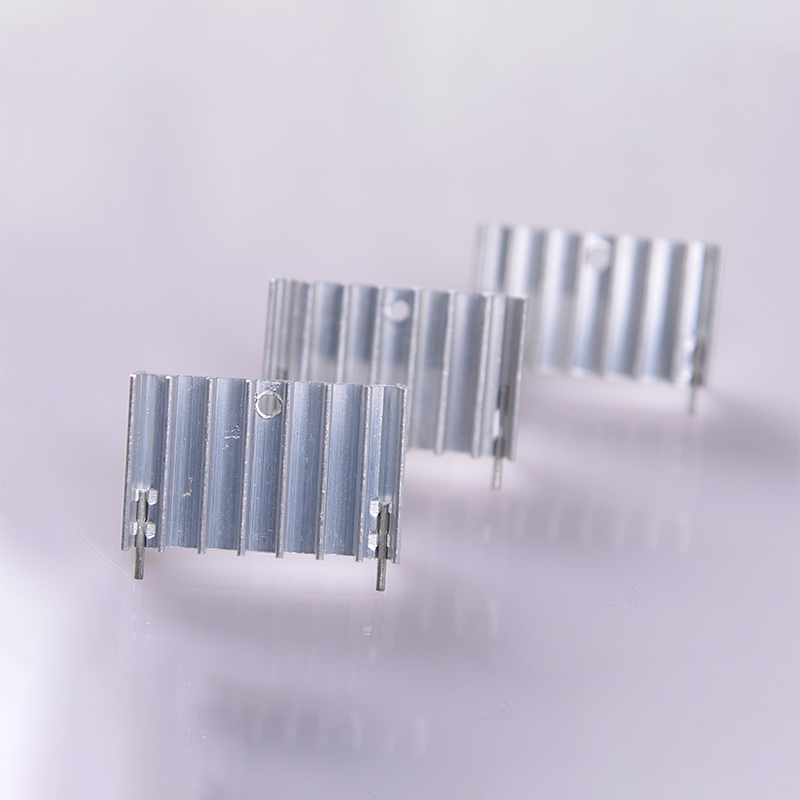

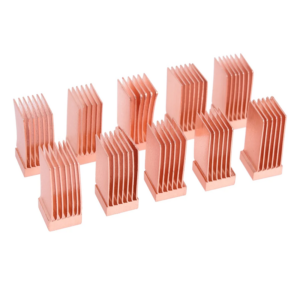

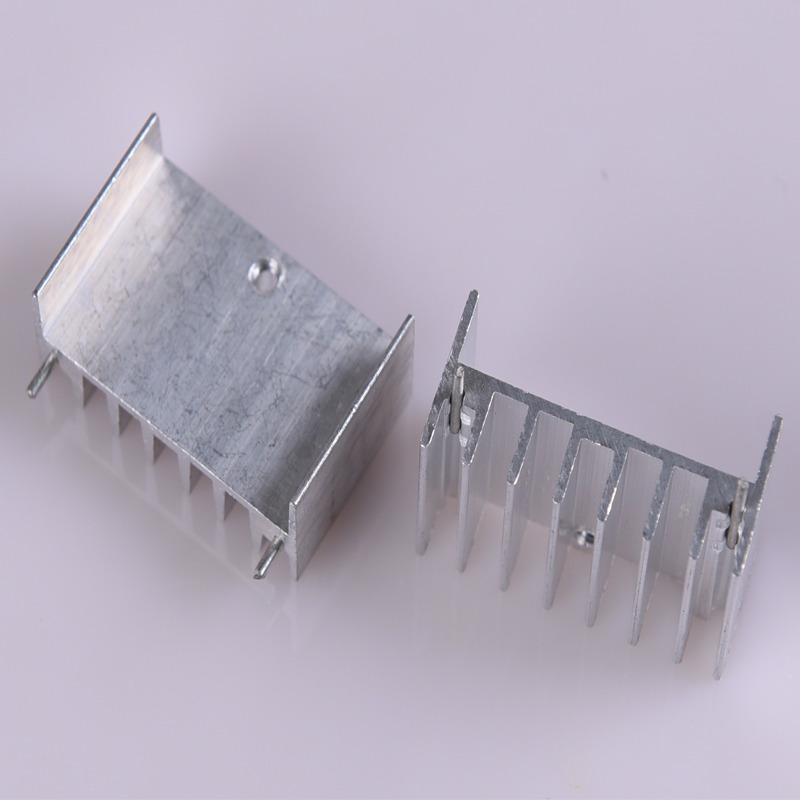

Ein gestanzter Kühlkörper für Computeranwendungen ist eine essentielle Lösung für das Wärmemanagement und wird durch fortschrittliche Techniken wie Extrusion, Druckguss oder Präzisionsbearbeitung hergestellt. Hergestellt aus hochleitfähigen Materialien wie Aluminium oder Kupfer, sind diese Kühlkörper so konstruiert, dass sie Wärme effektiv ableiten, thermische Überlastung verhindern und optimale Leistung und Haltbarkeit für CPUs und GPUs gewährleisten. Wir bieten auch OEM-Services an und liefern maßgeschneiderte Wärmemanagementlösungen, die auf Ihre spezifischen Bedürfnisse zugeschnitten sind und die Gesamtzuverlässigkeit und Effizienz Ihrer Systeme verbessern.

Merkmale:

| Attribut | Einzelheiten |

| Ursprungsort | Xiamen, China |

| Lieferzeit | Innerhalb von 7 Tagen |

| Anwendung | Computerkühlung |

| Form | Benutzerdefiniert |

| Bearbeitungsdienste | Biegen, Abwickeln, Schweißen, Stanzen, Schneiden |

| Material | Aluminiumlegierung |

| Anpassung | Anpassbar |

| Zertifizierung | ISO9001 / ROHS |

| Dienstleistung | OEM |

| Farbe | Wie abgebildet; Anpassung möglich |

Produktionsprozess:

- Materialauswahl: Hochleitfähige Materialien, typischerweise Aluminium oder Kupfer, werden basierend auf den Anforderungen des Wärmemanagements ausgewählt.

- Zuschnitt: Das ausgewählte Material wird auf die benötigte Größe und Form zugeschnitten, häufig unter Verwendung von Laserschneiden oder CNC-Bearbeitung, um präzise Abmessungen zu erreichen.

- Umformung: Je nach Design wird der Kühlkörper durch Verfahren wie Extrusion, Druckguss, Stanzen oder Schmieden geformt, um die erforderliche Rippenstruktur für eine effektive Wärmeableitung zu erzeugen.

- Oberflächenbehandlung: Um die Wärmeableitung zu verbessern und vor Korrosion zu schützen, wird der Kühlkörper Oberflächenbehandlungen wie Eloxieren oder Beschichten unterzogen.

- Assembly and Finishing: If the heat sink design includes multiple parts, they are assembled, followed by deburring, polishing, or coating as necessary to improve performance and aesthetics.

- Qualitätskontrolle: Strenge Tests werden durchgeführt, um sicherzustellen, dass der Kühlkörper die Standards für Wärmeleitfähigkeit, Maßhaltigkeit und Langlebigkeit erfüllt.

- Verpackung und Versand: Nach der Freigabe werden die Kühlkörper sorgfältig verpackt und für den Versand vorbereitet, um sicherzustellen, dass sie in einwandfreiem Zustand ankommen.

Oberflächenbehandlung für Kühlkörper:

- Pulverbeschichtung: Der Kühlkörper wird mit elektrostatisch aufgeladenem Pulver beschichtet. Diese widerstandsfähige Schutzschicht erhöht die Korrosionsbeständigkeit und verbessert die Optik.

- Sandstrahlen: Dieser Prozess raut die Oberfläche auf und erzeugt eine gleichmäßige Textur, die die Oberfläche vergrößert, wodurch die Wärmeableitung verbessert und die Haftung nachfolgender Beschichtungen erhöht wird.

- Lackierung: Eine Lackschicht wird aufgetragen, um zusätzlichen Schutz vor Umwelteinflüssen zu bieten und die Optik des Kühlkörpers zu verbessern.

- Walzblankes Finish: Der Kühlkörper behält nach der Bearbeitung seine natürliche metallische Oberfläche ohne zusätzliche Behandlung bei, was ihm ein sauberes, poliertes Aussehen verleiht.

Jede Behandlung verbessert die Haltbarkeit und Wärmeleistung des Kühlkörpers und bietet gleichzeitig Anpassungsmöglichkeiten für Aussehen und Funktionalität.

Fabrikvorführung: