Übersicht:

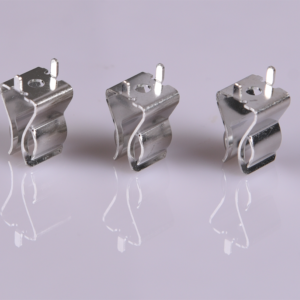

Manganstahl-Bremsbelag-Splitterclips werden sorgfältig entwickelt, um höchste Haltbarkeit, Präzision und Leistung zu gewährleisten und sind somit eine entscheidende Komponente in Fahrzeugbremssystemen. Bekannt für ihre hohe Festigkeit und Verschleißfestigkeit, sind diese Clips unerlässlich, um den extremen Drücken und Temperaturen beim Bremsen standzuhalten. Hergestellt mit fortschrittlicher Folgeverbundstanztechnologie, werden sie mit hoher Präzision produziert, um die strengsten Industriestandards zu erfüllen. Unsere Komplettlösungen bieten umfassende Leistungen, einschließlich kundenspezifischem Design, Prototypenbau und Serienfertigung, um sicherzustellen, dass jede Komponente die individuellen Anforderungen unserer Kunden erfüllt. Mit Fokus auf Qualität, Effizienz und Zuverlässigkeit liefern wir optimale Lösungen für diverse Automobilanwendungen.

Details:

| Attribut | Einzelheiten |

| Ursprungsort | Xiamen, China |

| Markenname | OEM |

| Prozess | Progressives Stanzen |

| Material | Edelstahl, Aluminium, Messing, Manganstahl usw. |

| Zertifikat | ISO9001, IATF16949 |

| Durchlaufzeit | Etwa 30 Tage |

| Toleranz | 0,01–0,05 mm |

| Größe | Maßgeschneiderte Größe |

| Produktname | Eloxierte Stanzteile, Blechbiegen |

| MOQ | Kleine Bestellung angenommen. |

| Beispiel | Verfügbar |

Produktionsprozess:

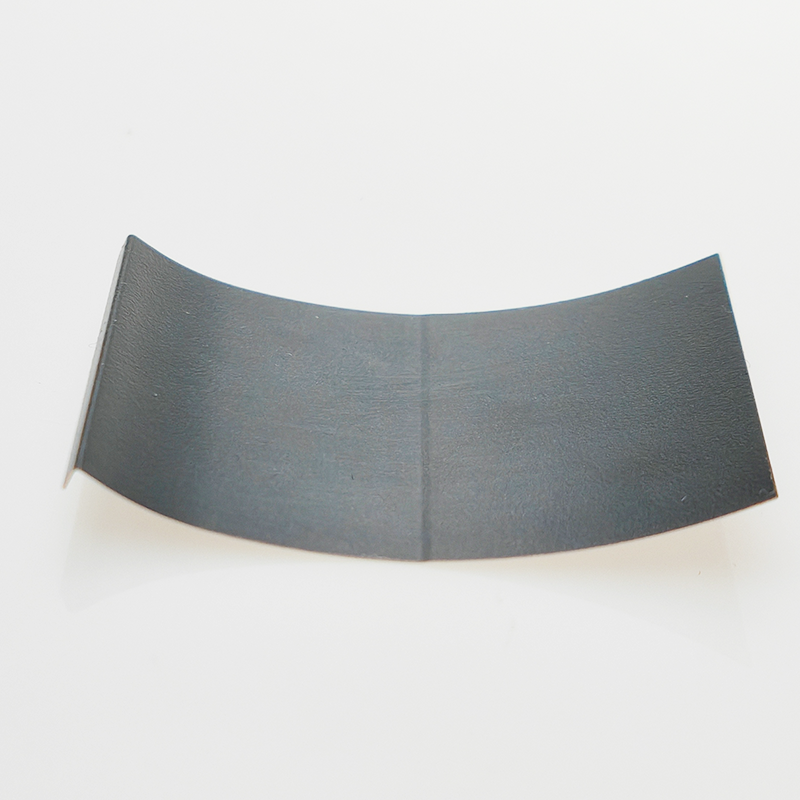

- Materialauswahl: Hochwertiger Manganstahl wird aufgrund seiner hervorragenden Festigkeit, Verschleißfestigkeit und Langlebigkeit sorgfältig ausgewählt.

- Schneiden und Scheren: Das ausgewählte Material wird mittels präziser Schneid- oder Scherverfahren in die gewünschte Form und Größe gebracht.

- Progressivstanzen: Das zugeschnittene Material wird durch ein Progressivstanzwerkzeug geführt, welches die Form der Klammer schrittweise durch eine Reihe von Stempeln und Matrizen formt.

- Wärmebehandlung: Die gestanzten Klammern werden wärmebehandelt, um ihre Härte und Festigkeit zu erhöhen und sicherzustellen, dass sie den anspruchsvollen Bedingungen von Fahrzeugbremssystemen standhalten.

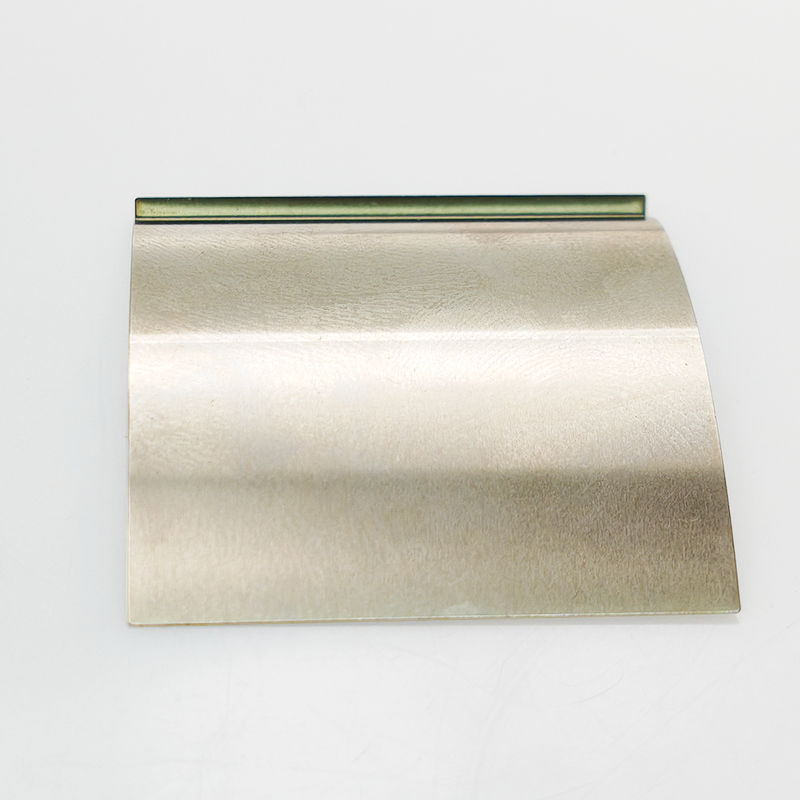

- Oberflächenbehandlung: Je nach Anwendung werden die Clips Oberflächenbehandlungen wie Galvanisieren, Eloxieren oder Polieren unterzogen, um die Korrosionsbeständigkeit, das Aussehen und die Haltbarkeit zu verbessern.

- Prüfung und Qualitätskontrolle: Jeder Clip wird strengen Prüfungen hinsichtlich Maßhaltigkeit, Oberflächenbeschaffenheit und Gesamtqualität unterzogen, um die Normen ISO 9001 und IATF 16949 zu erfüllen.

- Verpackung und Versand: Die fertigen Clips werden sorgfältig verpackt, um Transportschäden zu vermeiden, und gemäß den Kundenvorgaben versendet.

Oberflächenbehandlungsmöglichkeiten:

- Galvanisierung: Bei diesem Verfahren wird eine dünne Metallschicht, beispielsweise aus Zink oder Chrom, auf die Oberfläche der Klammern aufgebracht, um die Korrosionsbeständigkeit zu erhöhen und die Verschleißeigenschaften zu verbessern.

- Eloxieren: Dieses Verfahren wird hauptsächlich für Bauteile aus Aluminium verwendet und erzeugt eine dauerhafte, korrosionsbeständige Oxidschicht auf der Oberfläche. Diese bietet sowohl Schutz als auch ein attraktives Finish.

- Polieren: Dieses Verfahren glättet die Oberfläche der Clips auf Hochglanz, verbessert ihr Aussehen und reduziert die Reibung. Dies kann zu einer verbesserten Leistung und Langlebigkeit beitragen.

- Bürsten: Ein mechanisches Oberflächenveredelungsverfahren, das eine gleichmäßige, strukturierte Oberfläche erzeugt. Es wird häufig verwendet, um die Ästhetik zu verbessern und gleichzeitig einen gewissen Abriebwiderstand zu bieten.

Unsere Fabrik:

Wir betreiben eine Vielzahl modernster Anlagen und Maschinen, um höchste Produktionsqualität zu gewährleisten. Unsere Produktionsstätten sind mit 25 Stanzpressen von 25 bis 300 Tonnen Presskraft, Präzisions-Drahterodiermaschinen, Schleifanlagen, Schweiß- und Polierstationen sowie Ultraschallreinigungsanlagen ausgestattet. Dies ermöglicht es uns, ein breites Spektrum an Fertigungsanforderungen präzise zu erfüllen.

Über unsere robusten Fertigungsmöglichkeiten hinaus bieten wir eine Reihe von Metallbeschichtungsdienstleistungen an, die die Haltbarkeit, das Aussehen und die Leistung unserer Metallstanzprodukte verbessern. Zu diesen Dienstleistungen gehören Galvanisieren, Verzinken, Vernickeln, Verchromen und Eloxieren. Unsere hochmodernen Beschichtungsanlagen gewährleisten gleichbleibend hochwertige Oberflächen, die eine hervorragende Korrosionsbeständigkeit bieten und den höchsten Industriestandards entsprechen.

Die Integration von automatisierten Produktionslinien, fortschrittlichen Maschinen, strengen Qualitätskontrollprozessen und erstklassigen Beschichtungslösungen gewährleistet, dass wir stets Metallstanzteile liefern, die den anspruchsvollsten Spezifikationen entsprechen.