Übersicht:

In unserer Einrichtung sind wir auf die präzise Herstellung von kundenspezifischen Metallstanzteilen und Baugruppen spezialisiert. Zu unserem vielfältigen Produktsortiment gehören maßgeschneiderte Metallhalterungen, die entwickelt und hergestellt werden, um selbst die anspruchsvollsten Anwendungsspezifikationen zu erfüllen. Unsere kundenspezifischen Lösungen für Metallhalterungen umfassen eine breite Palette an Designoptionen, Materialauswahl, Oberflächenveredelungen und andere Anpassungen, um eine optimale Leistung in verschiedenen industriellen Anwendungen zu gewährleisten. Ob für strukturelle Unterstützung, Montage oder spezielle Funktionen – unsere maßgeschneiderten Metallhalterungen sind darauf ausgelegt, Erwartungen zu übertreffen.

Details:

| Attribut | Einzelheiten |

| Formtyp | Mehrstufige Folgeverbundwerkzeuge |

| Oberflächenbearbeitung | Galvanisieren, Feinschneiden |

| Prozesstyp | Formgebungsprozess |

| Industrie | Gestanzte Metallteile |

| Toleranzen | ±0.02mm |

| Anpassung | Verfügbar |

| Länge | 100-1000mm |

| Material | Edelstahl |

| Lieferzeit | 7-30 Tage |

| F&E-Kapazität | OEM |

| Spezifikation | Anpassung |

| Ursprungsort | China |

Fertigstellungsoptionen:

- Polieren: Erzielt eine glatte, glänzende Oberflächenveredelung für ein verbessertes Erscheinungsbild und erhöhte Haltbarkeit.

- Schlichte Ausführung: Eine einfache, unbeschichtete Oberfläche, ideal für minimalistische Designs und funktionale Anwendungen.

- Sandstrahlen: Bietet eine strukturierte, matte Oberfläche mit verbesserter Oberflächenrauheit für sowohl ästhetische als auch funktionale Zwecke.

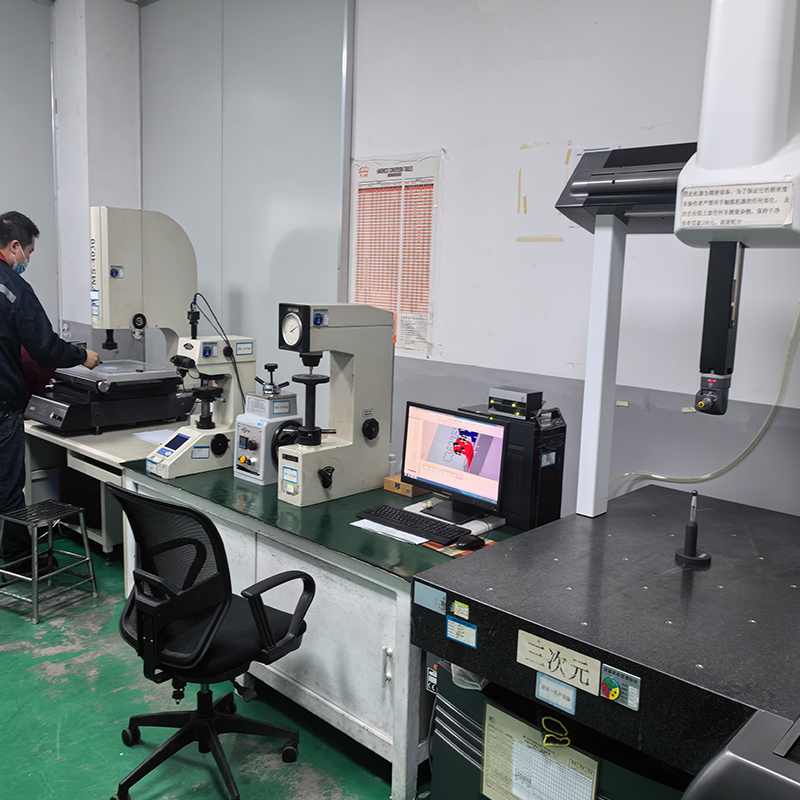

Qualitätsprüfungsprozess:

Der Qualitätstestprozess für gestanzte Metallblechhalterungen umfasst eine Reihe von strengen Prüfungen, um die Einhaltung von Industriestandards sicherzustellen. Zu den wichtigsten Tests gehören die dimensionale Überprüfung mit hochpräzisen Messinstrumenten wie Messschiebern und Koordinatenmessmaschinen (CMM), um die Genauigkeit innerhalb enger Toleranzen zu bestätigen. Die Oberflächenintegrität wird durch visuelle Inspektion sowie Prüfungen wie Salzsprühnebeltests zur Korrosionsbeständigkeit und Messung der Oberflächenrauhigkeit kontrolliert. Zusätzlich werden die mechanischen Eigenschaften wie Festigkeit und Flexibilität durch Zugtests und Bewertungen der Tragfähigkeit geprüft. Abschließend werden alle erforderlichen Funktionstests, einschließlich Pass- und Montageprüfungen, durchgeführt, um sicherzustellen, dass die Halterungen die festgelegten Anwendungsanforderungen erfüllen.

Unsere Dienstleistungen:

Wir sind spezialisiert auf die Herstellung von Befestigungselementen, die genau auf die Spezifikationen und Leistungsanforderungen der Käufer zugeschnitten sind.

Unsere Befestigungselemente durchlaufen strenge Haltbarkeitstests und technische Designbewertungen, um eine verlängerte Produktlebensdauer sicherzustellen.

Wir bieten wettbewerbsfähige Preise und liefern kosteneffiziente Lösungen, unterstützt durch unsere professionelle Fertigungskompetenz.

Mit über 20 Jahren Erfahrung bieten wir eine breite Palette an Befestigungslösungen, um jegliche Anwendungsanforderungen effektiv zu erfüllen.

Fabrikübersicht: