Übersicht:

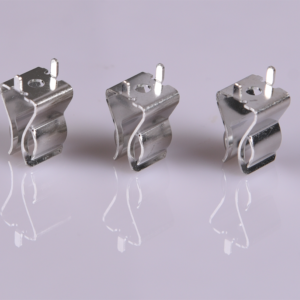

Gestanzte Metallklammern sind präzisionsgefertigte Befestigungselemente, die in Branchen wie der Automobilindustrie, Elektronik und Luft- und Raumfahrt weit verbreitet sind. Diese Klammern werden durch fortschrittliche Stanzverfahren hergestellt, einschließlich Schneiden, Formen und Biegen, um präzise Abmessungen und gleichbleibende Qualität zu erreichen. Typischerweise aus Materialien wie Edelstahl, Kohlenstoffstahl, Aluminium, Messing und Kupferlegierungen gefertigt, bieten gestanzte Metallklammern Haltbarkeit, Festigkeit sowie Verschleiß- und Korrosionsbeständigkeit. In unserem Werk bieten wir OEM-Services an, die die kundenspezifische Anpassung von Metallklammern in verschiedenen Größen, Formen und Oberflächen ermöglichen, um spezifische Kundenanforderungen zu erfüllen. Arbeiten Sie mit uns zusammen, um qualitativ hochwertige, maßgeschneiderte Lösungen zu erhalten, die Ihre Anwendungen verbessern.

Details:

| Kategorie | Einzelheiten |

| Verarbeitungstyp | Metall formen |

| Material | Kohlenstoffstahl |

| Schimmel | Mehrstufige Folgeverbundwerkzeuge |

| Prozess | Formgebungsprozess |

| Industrie | Gestanzte Metallteile |

| Toleranzen | 0,1 mm |

| Materialart | Aluminium, Messing, Edelstahl, Kupferblech |

| Ursprungsort | Xiamen, China |

| Technics | Stanzen, Lochen, Schleifen |

| F&E-Dienstleistung | Design und Zeichnung |

| Dimension | Angepasst |

| Lieferzeit | 30 Tage nach Zahlungseingang |

| OEM-Muster | Etwa 10 Tage |

| MOQ | Kleinaufträge werden angenommen. |

| Paket | Kundenspezifische Verpackung |

| Marke | OEM |

| Produktionskapazität | 50,000 PCS/Month |

Herstellungsprozess von gestanzten Metallklammern

-

Materialauswahl

Wählen Sie das passende Material, wie z. B. Edelstahl, Kohlenstoffstahl, Messing oder Aluminium, basierend auf den Anforderungen der Anwendung des Clips.

-

Werkzeug- und Gesenkvorbereitung

Konstruktion und Fertigung von mehrstufigen Folgeverbundwerkzeugen zur Gewährleistung präziser Formgebung und Umformung während der Produktion.

-

Schneiden und Stanzen

Rohe Metallbleche mit hochpräzisen Maschinen in vorgegebene Formen und Größen schneiden.

-

Formen und Gestalten

Führen Sie Biege-, Stanz- und Umformoperationen durch, um die gewünschte Clipstruktur zu erreichen, wobei auf Gleichmäßigkeit und Genauigkeit zu achten ist.

-

Sekundärprozesse

Wenden Sie zusätzliche Schritte wie Stanzen, Schleifen oder Gewindeschneiden an, um Merkmale zu verfeinern und die Funktionalität zu verbessern.

-

Oberflächenbehandlung

Verbessern Sie die Haltbarkeit und das Aussehen der Clips durch Behandlungen wie Plattieren, Polieren oder Eloxieren.

-

Qualitätsprüfung

Conduct rigorous testing to ensure dimensional accuracy, strength, and compliance with industry standards.

-

Anpassung und Montage

Kundenindividuelle Anforderungen, einschließlich spezifischer Abmessungen, Formen oder Oberflächen, werden berücksichtigt. Bei Bedarf erfolgt die Endmontage.

-

Verpackung und Lieferung

Verpacken Sie die Clips gemäß den Kundenvorgaben und bereiten Sie sie innerhalb des vereinbarten Zeitrahmens für den Versand vor.

Oberflächenbehandlung für gestanzte Metallklammern

-

Beschichtung

Tragen Sie Schutzschichten wie Zink, Nickel, Chrom oder Zinn auf, um die Korrosionsbeständigkeit, Haltbarkeit und das Aussehen zu verbessern.

-

Eloxieren

Verwenden Sie dieses elektrochemische Verfahren, um eine robuste Oxidschicht auf Aluminiumklammern zu erzeugen, die die Verschleißfestigkeit und die Ästhetik verbessert.

-

Pulverbeschichtung

Tragen Sie eine widerstandsfähige und gleichmäßige Beschichtung auf, um zusätzlichen Schutz vor Umwelteinflüssen zu gewährleisten und gleichzeitig eine glatte, polierte Oberfläche zu erzielen.

-

Polieren und Passivieren

Die Oberfläche des Clips durch Polieren verfeinern, um eine höhere Glätte und Glanz zu erzielen, und anschließend passivieren, um die Oxidations- und Korrosionsbeständigkeit zu erhöhen.

Unsere Fabrik:

Wir betreiben eine umfassende Auswahl an Anlagen und Ausrüstung, um eine Produktion von höchster Qualität sicherzustellen. Unsere Einrichtungen sind mit 25 Stanzpressen ausgestattet, die von 25 Tonnen bis 300 Tonnen reichen, präzisen Drahterodiermaschinen (Wire EDM), Schleifgeräten, Schweiß- und Polierwerkzeugen sowie Ultraschallreinigungssystemen.

Zusätzlich zu unseren Fertigungskapazitäten bieten wir eine Vielzahl von Metallbeschichtungsverfahren an, um die Haltbarkeit, das Erscheinungsbild und die Funktionalität unserer Metallprägeprodukte zu verbessern. Dazu gehören Galvanisierung, Zinkbeschichtung, Nickelbeschichtung, Chrombeschichtung und Anodisierung. Unsere hochmodernen Beschichtungsanlagen gewährleisten gleichmäßige Oberflächen, Korrosionsbeständigkeit und die Einhaltung von Industriestandards.

Diese Kombination aus professionellen und automatisierten Produktionslinien, fortschrittlicher mechanischer Ausrüstung, strengen Qualitätskontrollmaßnahmen und hochwertigen Beschichtungsverfahren gewährleistet, dass wir Metallstanzprodukte von höchstem Standard liefern.