Precisión en estampado de metal,

Custom Component Part

Ofrecemos servicios de estampado de metal integrales, desde el diseño inicial hasta la entrega final, incluyendo la selección de materiales, la optimización de procesos, la creación de prototipos rápidos y la producción a gran escala. Nuestra experiencia incluye procesos de estampado progresivo y de estampado por profundización, asegurando soluciones personalizadas con alta calidad y eficiencia para satisfacer sus necesidades específicas.

Su solución integral para servicios avanzados de estampado de metales

En Plantmetal, una división de Lingshantech, nos especializamos en el diseño y fabricación de troqueles progresivos complejos, procesos de embutición profunda de alta resistencia y servicios de estampado de metales de alta precisión. Contamos con 20 prensas que van desde 25 hasta 300 toneladas, equipadas con alimentación servoasistida y control de protección de troqueles, lo que nos permite realizar producción en masa en una amplia gama de materiales. Como fabricante líder OEM, respaldamos el estampado de metales a gran escala para industrias como la automotriz, electrónica y bienes de consumo, produciendo componentes como conectores electrónicos, contactos, clips y más. Nuestra inversión continua en equipos nos permite satisfacer las demandas en constante evolución de diversas industrias, mejorando la eficiencia de producción, los precios competitivos y la calidad del producto. Ofrecemos servicios integrales, que incluyen estampado de metales, ingeniería mecánica, diseño de prototipos, moldeo por inyección y soporte de fabricación. Nuestro enfoque colaborativo en el desarrollo de productos asegura que trabajemos estrechamente con los clientes para cumplir con sus especificaciones, preparando soluciones de diseño para fabricación (DFM) y garantizando entregas puntuales.

Proyectos de estampado destacados

LO QUE OFRECEMOS

Somos un proveedor de confianza especializado en la producción de componentes de hardware de precisión. Comprometidos con satisfacer constantemente sus necesidades, ofrecemos soluciones personalizadas que se adaptan a los requisitos específicos de la industria. Nuestros servicios principales están diseñados para ofrecer un rendimiento, calidad y fiabilidad superiores.

Nuestra instalación cuenta con 25 prensas de estampado, máquinas de corte por hilo EDM de precisión, equipos de rectificado, herramientas de soldadura y pulido, y sistemas de limpieza ultrasónica. Con capacidades avanzadas de procesamiento y pruebas, ofrecemos soluciones confiables y de alto rendimiento en estampado de metales, respaldadas por un riguroso control de calidad.

- Conectores Personalizados Estampados

- Manguito de embutición profunda

- Marcos de Plomo

- Clips metálicos

- Electronic Stamped Contacts

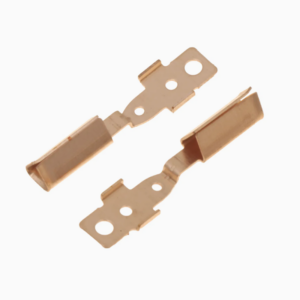

Conectores Personalizados Estampados

Material: Copper-5191

Post Process

Gold plating, silver plating, nickel-plating, tinplating

Applications of Custom stamped connectors

Aerospace Electronics: heavy duty aviation plug connector

New Energy: Heavy duty connector

Automotive: stamped connector

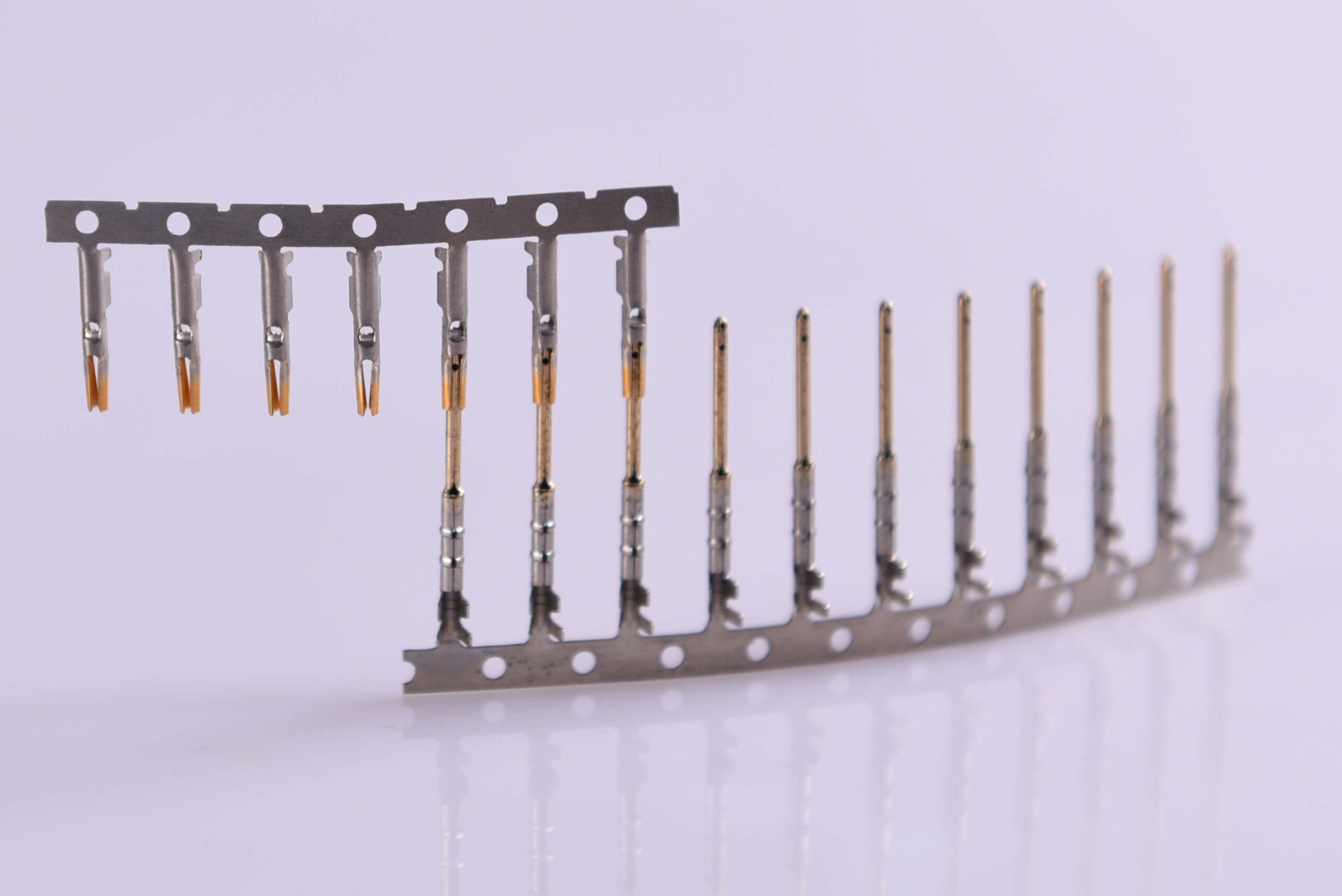

Deep Drawing Sleeve / Micro Deep Drawing Sensors Components

Material: Stainless steel 301/304, Aluminum-5052, Copper-1100,Copper-5191,Brass-6265,7275

Post Process

Stainless Steel: Passivation

Aluminum: Anodization

Copper: nickel plating, tinplating

Application Industry - Main industry sensor deep drawing parts

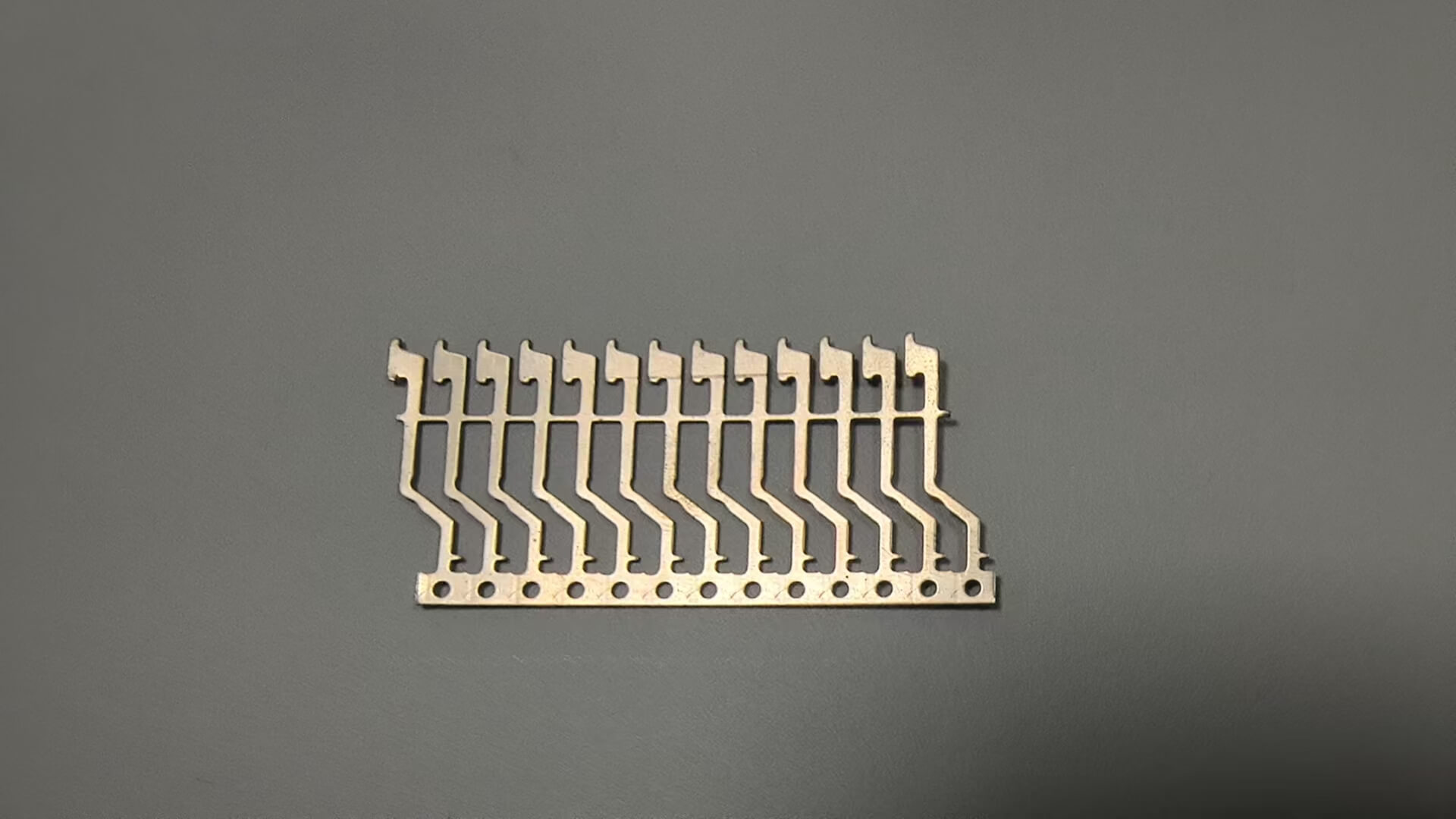

Marcos de Plomo

Material: Copper-1100

Post Process

Copper: Passivation, Golden plating, silver plating, nickel plating, tinplating

Applications : Semiconductor and Electronics Industry,Automotive Electronics Industry,Telecommunications Industry,Consumer Electronics Industry,Industrial Control and Automation,Medical Equipment Industry

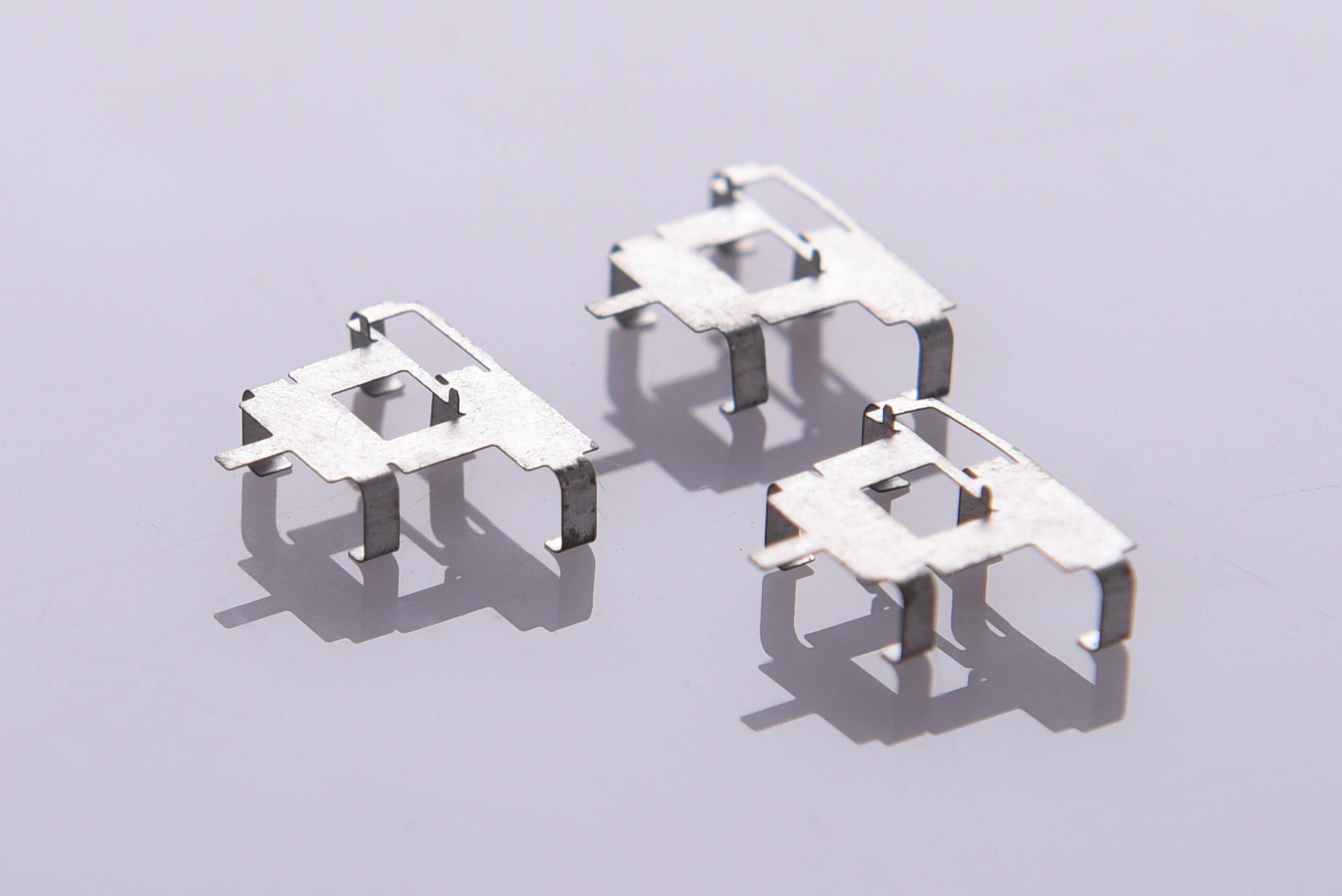

Car Air Control Button Shrapnel Metal Stamping Clips

Material: SUS301/631

Post Process

Copper: Passivation, Golden plating, silver plating, nickel plating, tinplating

Stainless Steel-Acid passivation, Temper to 250-280 ° C

Terminal Connectors

Material: Copper-1100,Copper-5191,Brass-6265,7275

Post Process

Copper: Golden plating, silver plating, nickel plating, tinplating

Working With Plantmetal

¿Por qué elegirnos?

Estado de la Técnica y Tecnología

Our investment in cutting-edge metal stamping equipment and technology includes high-speed presses, multi-station dies, and automated production lines. Utilizing these advanced tools enables us to achieve higher production speeds and greater efficiency in metal stamping operations.

Multi-Station Stamping Technology

We leverage multi-station stamping technology, allowing multiple processes such as cutting, bending, forming, and piercing to be executed simultaneously on a single press. This technology enhances production efficiency and reduces component handling and movement, leading to lower production costs.

Quality Assurance and Certification

Our commitment to delivering high-quality metal stampings is evidenced by our ISO 9001 and IATF 16949 certifications. We enforce rigorous quality control measures throughout the production process, including material inspection, process control, and finished product testing, ensuring each product meets stringent customer and industry standards.

High Precision and Consistency

We meticulously control process parameters and quality requirements at each production step to guarantee the precision and consistency of every metal stamping. Utilizing advanced measurement equipment and quality control tools, we ensure each product adheres to the specified requirements.

Material Selection and Optimization

We collaborate with suppliers to choose high-quality metal materials and optimize them based on customer specifications. This strategic material selection and optimization enhance the strength, corrosion resistance, and wear resistance of our products, meeting diverse application needs.

Engineering Support and Collaboration

Our experienced engineering team works closely with customers, providing technical support and solutions. We offer expertise in product design, process optimization, and cost control, helping customers achieve the best possible metal stamping solutions.