At Plantmetal, we understand the critical role metal surface treatments play in ensuring the durability, functionality, and visual appeal of metal parts across various industries. Whether you’re in transportation, technology, construction, or another field, choosing the right surface treatment can significantly enhance your product’s performance and service life. Let’s explore the most commonly used surface treatment processes, their unique benefits, and how they can be tailored to your specific use environment.

Understanding the Importance of Surface Treatments

Surface treatment is more than just a finishing touch—it’s a vital process that prepares metal components for the demands of their application. By applying specialized coatings or treatments, manufacturers can improve a part’s resistance to wear, corrosion, and environmental factors, while also achieving the desired aesthetic qualities. With expertise in CNC metal manufacturing and surface finishing, Plantmetal is here to guide you in selecting the most effective treatment for your needs.

Common Surface Treatment Processes

-

Anodizado

Anodizing is primarily used for aluminum and aluminum alloy materials. This electrochemical process forms a robust oxide film on the metal surface, offering several advantages:

– Improved Durability: Increases surface hardness and wear resistance.

– Enhanced Corrosion Resistance: Protects the material from environmental degradation.

– Aesthetic Versatility: Allows for decorative finishes in various colors.

– Functional Benefits: Reduces electrical conductivity, making it ideal for heat dissipation and minimizing surface reflections in specific applications.

Anodizing is particularly favored in industries where a combination of durability and a sleek appearance is required, such as consumer electronics and aerospace.

-

Chapado

Plating involves depositing a thin metal layer onto the surface of a part, improving its properties and appearance. This versatile process is applicable to nearly all metallic materials. Key benefits include:

– Corrosion Resistance: Protects the metal from rust and oxidation.

– Enhanced Conductivity: Essential for components in electronic applications.

– Aesthetic Appeal: Provides a polished, professional finish.

Common plating materials include gold, silver, nickel, zinc, and tin, each offering unique benefits tailored to specific industrial requirements.

-

Electrophoresis

Electrophoresis is a coating technique that uses an electric field to evenly deposit particles onto the surface of a metal part. This method is ideal for:

– High Adhesion: Prevents peeling or detachment of the surface layer.

– Versatile Color Options: Produces a wide range of colors for customized finishes.

– Complex Structures: Effectively coats intricate shapes and hard-to-reach areas.

Electrophoresis is commonly used in the automotive and consumer goods industries to enhance both functionality and design.

-

Recubrimiento en Polvo

Powder coating is a cost-effective method where powdered paint is electrostatically applied and then baked to form a durable, smooth finish. Benefits include:

– Strong Protective Layer: Guards against scratches and environmental damage.

– Cost-Effectiveness: An economical choice for large-scale production.

– Defect Masking: Conceals imperfections for a flawless appearance.

This method is widely used in industrial equipment, household appliances, and construction materials due to its durability and efficiency.

-

Molienda

Grinding creates regular shallow lines on the metal surface, offering both functional and decorative benefits. Different types of grinding effects include:

– Straight Grain: A clean, linear look.

– Chaotic Grain: Adds texture with a random finish.

– Corrugated Grain: Features wavy patterns for aesthetic appeal.

– Swirling Grain: Provides a unique, circular texture.

Grinding not only improves the appearance but also removes minor surface flaws, making it a versatile option for various industries.

-

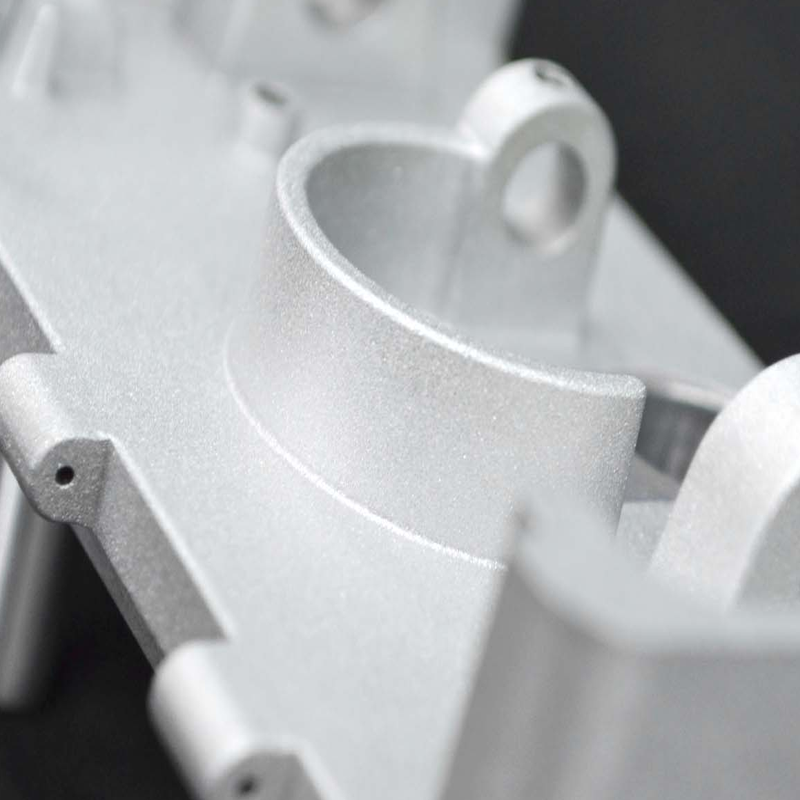

Arenado

Sandblasting uses high-pressure jets of abrasive material to clean and roughen the surface of a metal part. Its benefits include:

– Enhanced Adhesion: Prepares the surface for subsequent treatments, such as painting or coating.

– Customizable Roughness: Adjusts the texture based on application needs.

This process is commonly used as a pre-treatment step for coatings or to achieve a uniform matte finish.

-

Pulido

Polishing enhances the metal’s surface by reducing roughness to create a smooth, bright finish. It offers:

– Improved Aesthetics: Provides a mirror-like shine for premium applications.

– Preservation of Material Properties: Does not alter the original physical attributes of the material.

Polishing is often the final step for decorative items, precision instruments, and luxury products.

Factors to Consider When Choosing a Surface Treatment

Selecting the right surface treatment depends on several factors:

- Use Environment: Consider exposure to elements like moisture, heat, or corrosive substances.

- Functional Requirements: Evaluate the need for properties like wear resistance, conductivity, or adhesion.

- Aesthetic Goals: Determine the desired finish, texture, or color.

- Budget Constraints: Balance cost with performance requirements for an efficient solution.

At Plantmetal, our experts work closely with you to assess these factors and recommend the most effective surface treatment to optimize your product’s performance and lifespan.

Partner with Plantmetal for Exceptional Surface Treatment Solutions

Choosing the appropriate surface treatment for your metal parts is critical to achieving both performance and aesthetic excellence. At Plantmetal, we specialize in providing tailored solutions for every industry, ensuring that your products meet the highest standards of quality and functionality.

Have questions about the best surface treatment for your application? Contact us today, and let our team of experts guide you through the selection process. Together, we’ll ensure your metal parts are ready to perform flawlessly in any environment.