Resumen:

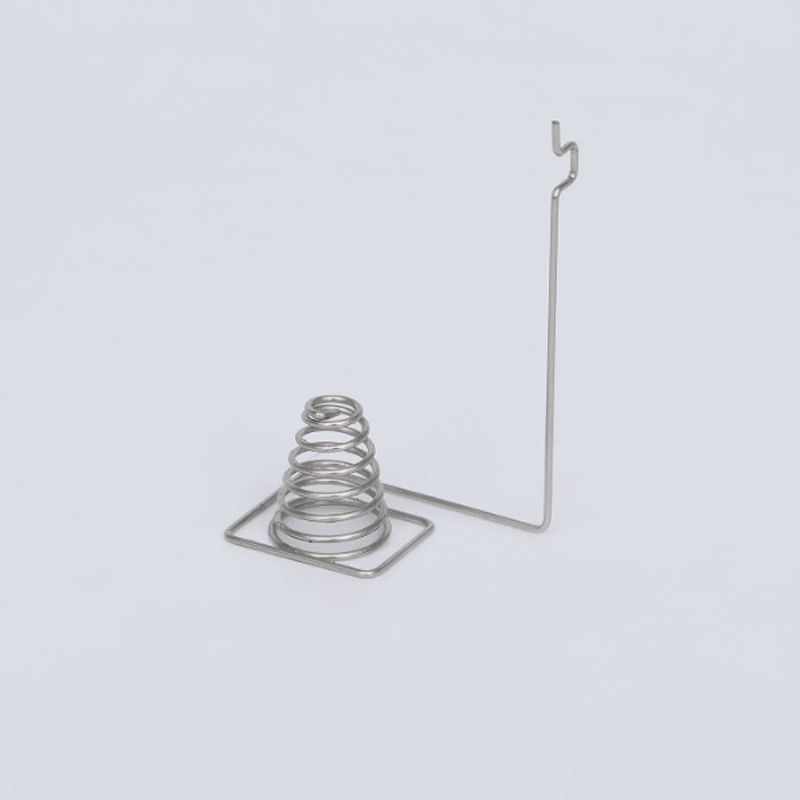

Electroplating high carbon steel wire forming stamping spring is a high-performance component created by electroplating high-carbon steel wire, suitable for diverse industries. Wire forming includes processes like bending, piercing, swaging, and chamfering to shape wire materials. This technique is widely used in food production, automotive, shipping, and medical sectors. Our factory offers custom stamping springs with various materials and surface treatments, ensuring durability and precision. Whether you require corrosion resistance or added strength, we deliver tailored solutions to meet your specific needs.

Detalles:

| Atributo | Detalles |

| Lugar de origen | Fujian, China |

| Material | High Carbon Steel |

| Color | Color personalizado |

| Tamaño | Tamaño personalizado |

| MOQ | Small order can be accepted |

| OEM | Ofrecido |

| Tiempo de entrega | 7-25 Working Days |

| Calidad | High-Quality |

| Certificaciones | ISO9001, IATF16949 |

The Advantages of Our Products:

- Electrical Appliance Applications

- Lighting Fixture Solutions

- Custom Wire Spring Manufacturing

- Diverse Industry Applications

Tratamientos de Superficie:

- Heat Treatment:Enhances material strength and durability through controlled heating and cooling.

- Passivation:Improves corrosion resistance by forming a protective oxide layer.

- Black Oxide:Applies a black finish for corrosion resistance and reduced friction.

- Galvanizing:Coats steel or iron with zinc to prevent rust and prolong lifespan.

Proceso de Producción:

- Wire Preparation:High carbon steel wire is carefully selected and cut to the required length for the stamping spring.

- Wire Forming:The wire is shaped through processes like bending, piercing, and swaging to achieve the desired form.

- Electroplating:A layer of metal, such as nickel or chrome, is applied to the formed wire to enhance corrosion resistance and improve surface finish.

- Heat Treatment:The formed and electroplated wire is heat-treated to improve its hardness, strength, and overall durability.

- Surface Finishing:Additional treatments, such as passivation or black oxide coating, may be applied for further corrosion resistance and aesthetic appeal.

- Quality Control:Each stamping spring undergoes rigorous inspection to ensure it meets specifications and quality standards.

- Packaging:The finished springs are packaged for delivery, ensuring protection during shipping.

Nuestra Fábrica:

We operate a fully equipped facility to deliver the highest quality metal stamping products. Our production includes 25 punch presses ranging from 25 to 300 tons, precision wire EDM machines, grinding equipment, welding and polishing tools, and ultrasonic cleaning systems.

To enhance product durability, appearance, and functionality, we offer a range of advanced metal plating processes, such as electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our cutting-edge plating facilities ensure consistent finishes, corrosion resistance, and compliance with industry standards.

Our manufacturing capabilities, coupled with ISO9001 and IATF16949 certifications, ensure top-tier quality control and the delivery of exceptional metal stamping products.