Selecting the right metal stamping partner is a critical decision that directly impacts the quality, cost, and timeline of your manufacturing project. Metal stamping, a highly specialized manufacturing process, uses a press along with custom tooling and dies to shape sheet metal into specific forms. It’s widely used to produce industrial components for sectors like automotive, aerospace, medical devices, telecommunications, and more. When looking for a metal stamping partner, it’s important to consider a range of factors beyond just the ability to meet your immediate production needs. The best partner will be one who can offer the greatest value through a combination of capabilities, experience, and customer support.

In this blog post, we’ll walk through the essential considerations to keep in mind when choosing a metal stamping partner, helping you identify the qualities that define a high-value partner who can deliver high-quality results.

1. Understanding the Role of a Partner vs. a Supplier

The first distinction you need to understand when choosing a metal stamping company is the difference between a supplier and a partner. A supplier is typically a company that provides a product or service based on a direct order, but a partner goes beyond that. While a supplier can meet your specific requirements for a stamping job, a partner offers more comprehensive services.

A true metal stamping partner will not only provide precision stamping services but will also be capable of offering design support, engineering assistance, and post-production services such as assembly, finishing, and packaging. These additional capabilities can drastically reduce lead times and lower overall production costs, as the partner can handle multiple stages of production in-house. Partnering with a company that can manage the entire process from initial design through final delivery can streamline your operations, improve quality control, and ensure better project outcomes.

2. Evaluating Advanced Stamping Capabilities

While it’s important to select a company with strong metal stamping capabilities, it’s equally important to ensure that the company has a diverse range of in-house stamping processes. Different projects often require different techniques, and a versatile metal stamping partner can offer the flexibility to accommodate a variety of needs.

For instance, a partner with experience in blanking, piercing, bending, embossing, and coin stamping will be able to handle a broader range of components. On the other hand, if your project requires more advanced processes, such as deep drawing or progressive die stamping, it’s crucial to choose a partner who specializes in these areas to ensure high-quality results.

Not all metal stamping projects are straightforward, and sometimes the best process may not be immediately apparent. Working with a partner that has a wide array of stamping techniques allows for better decision-making and ensures that the best process is used for each specific project.

3. Tooling Design and Development

A key advantage of working with an experienced metal stamping partner is their ability to handle tooling design and development in-house. Tooling, which includes the creation of custom dies and molds, is one of the most critical aspects of the metal stamping process. The quality of the tooling directly impacts the precision and quality of the stamped parts.

A stamping company that offers custom tooling design services can provide a higher level of precision and greater control over the manufacturing process. With an in-house tooling team, your partner can create bespoke tooling for your project, ensuring that the components meet the exact specifications. This also allows for quicker turnaround times and minimizes the risk of tooling-related delays, as there is less reliance on third-party suppliers for tooling production.

4. Comprehensive Secondary Services

While stamping itself is the core of the process, many projects require additional services beyond stamping to meet final product requirements. A well-rounded metal stamping partner will offer a range of secondary services that can save you time and money by consolidating multiple steps of the manufacturing process under one roof.

Some of the secondary operations a top-tier stamping partner might offer include:

- Heat treatmentand forming for parts requiring specific strength or shape

- Weldingand assembly services to reduce the need for outsourcing

- Painting, electrocoating, and platingoptions like zinc plating, nickel plating, chrome plating, or anodizing to enhance part durability and appearance

- Passivation, sterilization, and deburred edge finishingto ensure part safety and usability

- Kittingand custom packaging for efficient shipping and final product assembly

These secondary services offer added value to customers, allowing you to source all your needs from one provider, which can simplify project management and improve overall cost-effectiveness.

5. Industry Experience and Specialization

It’s vital to partner with a metal stamping company that understands the specific requirements and challenges of your industry. For example, a medical device manufacturer will have different compliance and material requirements than an automotive or aerospace company.

Look for a stamping partner that has extensive experience in your specific industry. This experience ensures that they are familiar with the unique regulatory standards, material specifications, and production processes required for your components. A well-versed partner will also have the know-how to handle any industry-specific challenges that might arise during the project.

6. Production Capacity and Flexibility

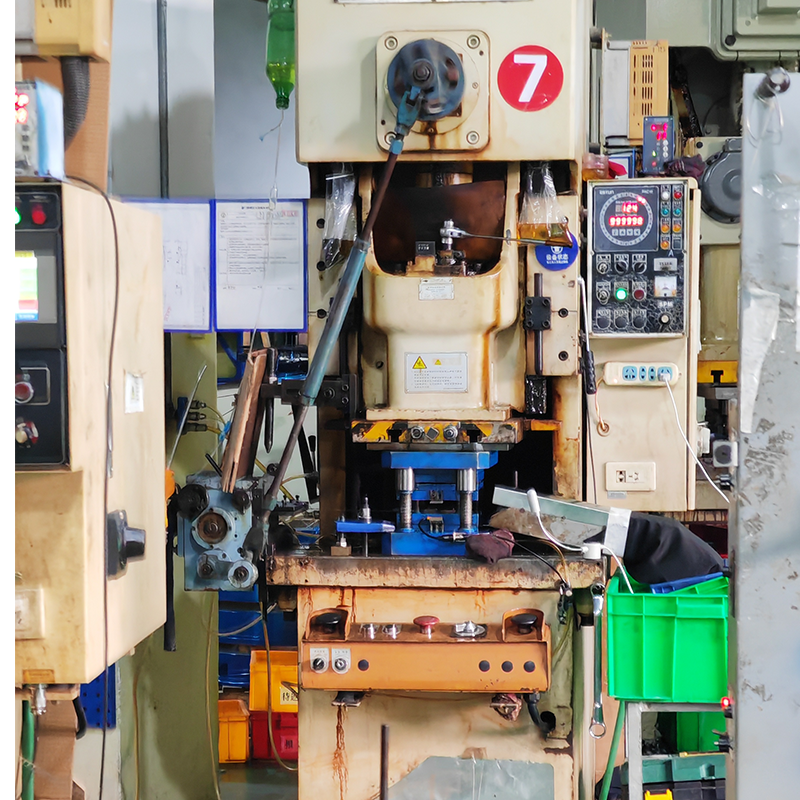

The ability to scale production quickly and efficiently is an important consideration when selecting a metal stamping partner. Assess a potential partner’s production capacity to ensure they can meet your volume requirements within the necessary lead times.

A reliable metal stamping partner should be equipped with modern equipment and machinery that allow for high-efficiency production while maintaining precision. Whether you need high-volume runs for mass production or low-volume runs for prototypes, the partner’s production capacity should align with your project’s needs.

7. Quality Management and Certifications

Ensuring consistent quality throughout the stamping process is crucial. The best metal stamping companies maintain robust quality management systems to meet stringent industry standards. Look for a partner that holds relevant certifications, such as ISO 9001:2015 or IATF 16949, which demonstrate their commitment to quality and continuous improvement. These certifications are indicative of a company’s ability to deliver products that meet high standards of precision, reliability, and performance.

Conclusion

Choosing the right metal stamping partner is more than just selecting a vendor—it’s about finding a long-term partner who can meet your needs across all stages of production, from design to final delivery. The ideal partner will offer a range of services, advanced capabilities, industry-specific expertise, and a commitment to quality that ensures the success of your project.

At Plantmetal, we specialize in providing custom metal stamping solutions for industries ranging from aerospace and automotive to medical devices and renewable energy. With over 60 years of experience, we offer comprehensive services including tooling design, secondary operations, and industry-compliant production, all backed by our ISO 9001:2015 and IATF 16949 certifications.

Whether you need high-volume production, complex components, or custom solutions, we are ready to help you streamline your manufacturing process. To learn more about how we can support your next project, contact us today or request a quote. Let’s collaborate to bring your vision to life with precision and efficiency.