Resumen:

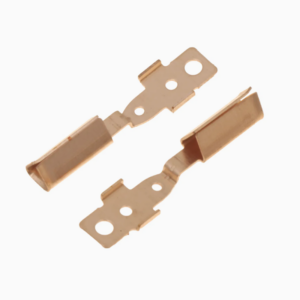

Our factory specializes in OEM and custom metal stamping services, producing precision brass terminals for sheet metal fabrication with advanced CNC stamping and multi-stage forming technology. Crafted from premium C26000/C27200 brass alloys, our terminals deliver superior conductivity, corrosion resistance, and mechanical strength with strict tolerances (±0.005″) and finishes (tin, nickel, or bare brass). Backed by ISO-certified quality control and rapid prototyping, we support high-volume orders and custom designs for electrical, automotive, and industrial applications. Request a quote for reliable, cost-effective stamped brass components.

Información básica:

| Parámetro | Detalles |

| Lugar de origen | Xiamen, China |

| Nombre de la Marca | OEM |

| Tolerancia | 0.01-0.1mm |

| OEM | Ofrecido |

| Assessed Reports | ISO:9001:2015, IATF16946:2016, RoHS |

| Material | Copper-5191, C-1100, Copper Alloy, Brass, Silver, Stainless Steel, Aluminum |

| Tiempo de muestra | 10-20 days |

| Aplicación | Sheet metal fabrication / auto parts / motorcycle parts, etc. |

| Shipping Terms | Express, Sea shipment, Air shipment |

| Quality Guaranteed | 100% responsible for quality problems |

| Tecnología | Estampación Metálica |

Opciones de Tratamiento de Superficie:

- Nickel Plating: Enhances corrosion resistance and durability.

- Tin Plating: Improves solderability while protecting against oxidation.

- Silver Plating: Provides excellent electrical conductivity with a bright finish.

- Gold Plating:Offers superior conductivity and exceptional tarnish resistance.

Quality Control:

Quality control for metal stamping brass terminals in sheet metal fabrication encompasses several key components to ensure precision and reliability. This includes verifying dimensional accuracy using advanced tools like coordinate measuring machines (CMMs) and optical comparators, conducting material composition analysis via X-ray fluorescence (XRF) spectrometers, and inspecting surface finishes for imperfections like burrs or cracks with automated vision systems. Mechanical properties such as hardness are tested using Rockwell or microhardness testers, while corrosion resistance is validated through salt spray chambers per ASTM B117 standards. Certifications like ISO 9001 and IATF 16949 (for automotive applications) are typically required, with production often monitored through statistical process control (SPC) software. State-of-the-art progressive stamping presses with servo-driven automation ensure repeatability, complemented by force monitors and in-line gauging systems for real-time defect detection during high-volume production.

Descripción general de la fábrica:

Our facility utilizes state-of-the-art manufacturing technology to achieve unparalleled precision and quality. We are equipped with 25 high-performance punch presses (ranging from 25 to 300 tons), precision wire EDM machines, advanced grinding systems, and specialized welding, polishing, and ultrasonic cleaning equipment, ensuring exceptional surface finishes and cleanliness.

In addition, we offer a comprehensive range of metal plating solutions, including electroplating, zinc plating, nickel plating, chrome plating, and anodizing. These treatments provide uniform coatings, superior corrosion resistance, and full compliance with industry standards.

With fully automated production lines and strict quality control protocols, we proudly maintain ISO 9001 and IATF 16949 certifications, guaranteeing exceptional reliability, precision, and durability in every aspect of our metal stamping manufacturing processes.