Choosing the right connector components is essential for ensuring optimal current flow in various devices. Copper and aluminum connectors are the two most widely utilized materials for these components. In this article, we will explore what electrical connectors are, their functions, the key differences between copper and aluminum connectors, and ultimately determine which material is more efficient for conducting current.

What Is Electrical Connectors

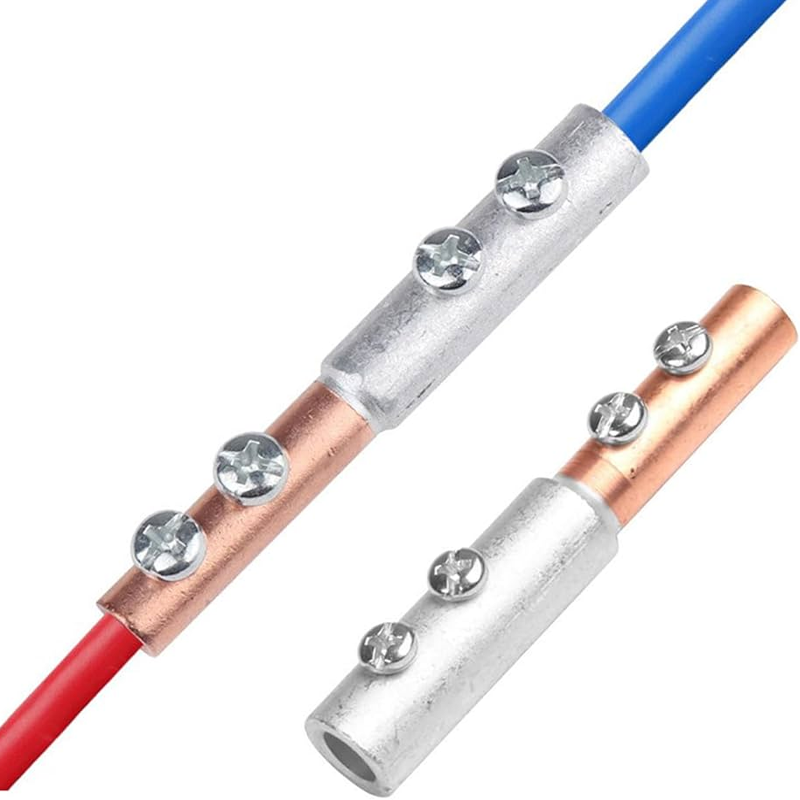

Electrical connectors, often referred to as cable terminations, are critical components used to join specific cables and wires. They facilitate connections for various applications, such as grounding metal elements in machinery or linking control components. While a variety of materials—including nickel, bronze, steel, and brass—are available for connectors, copper and aluminum are predominant due to their superior conductivity properties. The choice of material significantly influences the performance and reliability of the connection.

Key Considerations of Copper Connectors

Copper has established itself as a leading choice in the industry due to its exceptional electrical conductivity. It features very low electrical resistance, allowing for a seamless flow of current. When selecting copper connectors, it is important to consider their various advantages:

– High Conductivity: Copper connectors excel in conductivity, ensuring efficient power transmission.

– Durability: Known for their resilience, copper connectors are less prone to wear and tear.

– Flexibility: The inherent plasticity of copper allows for a secure fit with other connectors, creating reliable connections.

– Thermal Conductivity: Copper’s ability to dissipate heat effectively reduces the risk of overheating, enhancing connection reliability.

– Ease of Production: The material is relatively easy to process, facilitating the manufacturing of connectors.

– Recyclability: Copper is a sustainable option as it can be recycled without loss of properties.

The combination of these attributes makes copper connectors particularly suitable for high-performance applications, especially where data transmission speed and reliability are paramount.

Applications of Copper Connectors

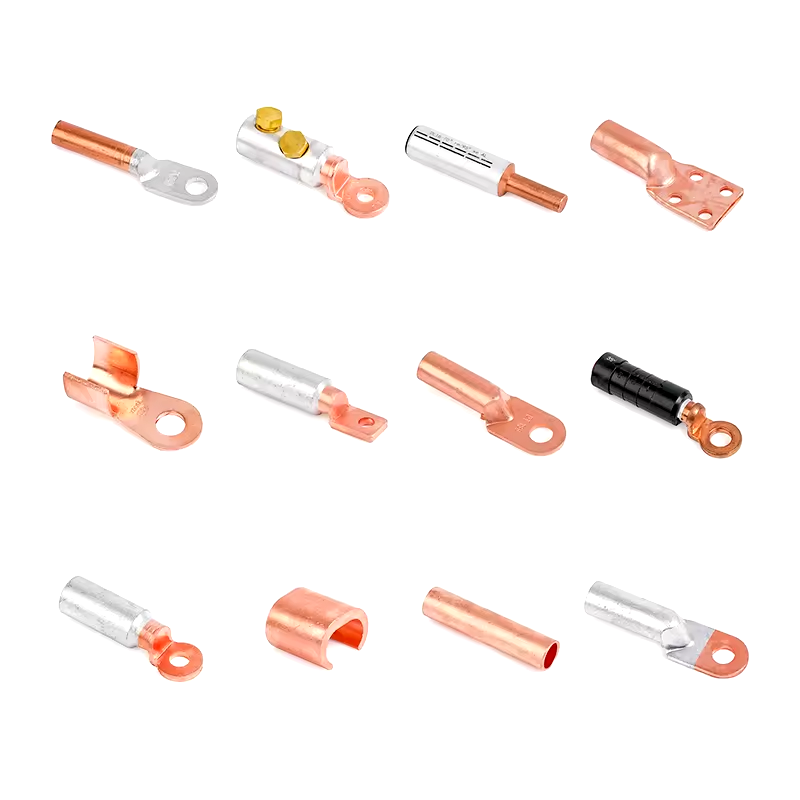

Copper connectors are widely used in numerous applications, including:

– High-Power Electrical Installations: In industrial settings, copper connectors ensure proper current transmission in high-power setups, such as relays and switches.

– Automotive and Battery Systems: Copper connectors provide the best balance of cost and performance, making them essential for electrical systems in vehicles and e-mobility applications.

– Chemical Industry: They are used extensively for connecting pipelines and cables, ensuring robust connections in harsh environments.

However, it is worth noting that copper connectors tend to be more expensive due to the cost of raw materials. Consequently, some manufacturers opt for connectors with a copper core covered by other less expensive materials.

The Characteristics and Usage of Aluminum Connectors

Aluminum connectors are renowned for being lightweight yet durable, making them ideal for applications where weight is a critical factor, such as in the aviation and automotive sectors. Their corrosion resistance also makes them suitable for outdoor applications exposed to harsh weather conditions. However, aluminum connectors have some limitations:

– Electrical Properties: Aluminum is less conductive than copper, which can impact efficiency in high-current applications.

– Mechanical Strength: While generally durable, aluminum connectors may lack the mechanical strength of copper unless properly designed.

– Electrolytic Corrosion: Aluminum is more susceptible to electrolytic corrosion, which can degrade the integrity of the connection over time.

An Overview of Insulated Connectors

Insulated connectors consist of two parts: the insulator and the wire. The insulation acts as a protective layer, preventing damage and ensuring safety. Various terminations are available, such as eyelet, needle, flat, or fork styles. It is crucial to select the appropriate type of insulated connector for specific applications to ensure optimal performance.

Comparing Copper and Aluminum Connectors

When deciding between copper and aluminum connectors, several factors must be considered:

- Current Capacity: For high-current applications, copper connectors are generally more effective due to their superior conductivity. They facilitate efficient energy transmission, making them the preferred choice in demanding scenarios.

- Weight Considerations: If minimizing weight is a priority, aluminum connectors are advantageous. They offer a lightweight alternative without compromising too much on durability.

- Cost Efficiency: Aluminum connectors are typically less expensive than their copper counterparts, making them a more budget-friendly option for many applications.

- Environmental Conditions: Copper’s superior conductivity makes it ideal for high-performance environments, while aluminum’s corrosion resistance is beneficial for outdoor applications.

Innovative Solutions at Plantmetal

At Plantmetal, we recognize the distinctive advantages of copper in connector applications. Our commitment to quality ensures that we offer high-performance copper connectors suitable for a wide range of industries. Our product lineup includes specialized copper connectors that withstand high temperatures and deliver exceptional electrical performance.

Additionally, we manufacture aluminum connectors, pins, and a variety of other components, including bus bars, laminated parts, and radiators. Each of our products is designed to meet the rigorous demands of our customers, ensuring reliability and efficiency in every application.

Conclusion

Choosing between copper and aluminum connectors requires a thorough understanding of their respective properties and applications. While copper connectors excel in high-current environments due to their superior conductivity and durability, aluminum connectors provide a lightweight and cost-effective alternative suitable for various applications.

At Plantmetal, we are dedicated to providing innovative and reliable solutions to meet the diverse needs of our clients. Whether you require high-quality copper connectors or versatile aluminum options, we invite you to explore our product offerings. Contact us today to discover how we can assist you in achieving your electrical connection needs.