Description :

Custom stamping stainless steel metal clips are precision-engineered components made through the metal stamping process, utilizing high-quality materials such as stainless steel, spring steel, and carbon steel. These clips are crafted to meet specific performance requirements in various applications, including automotive, aerospace, and industrial machinery. We offer custom sizes and a wide range of surface treatment options, such as zinc coating, black oxide, or passivation, to enhance durability, corrosion resistance, and overall performance.

Metal stamping clips can function as clamps, fasteners, or brackets, applying pressure to securely hold objects together. Our custom metal clips are widely used in applications such as instrument panels, fender assemblies, ABS brake systems, and control switches. With our expertise in custom design and precision manufacturing, we provide solutions that meet your exact specifications and ensure high-quality, reliable performance in demanding environments.

Caractéristiques :

| Attribut | Détails |

| Type de traitement | Façonnage du métal |

| Matériau | Zinc, Aluminum, Copper, Steel, Brass, etc. |

| Moule | Matrices progressives à étapes multiples |

| Découpage Fin | Multi-Position |

| Processus | Stamping, Bending, Laser Cutting, Welding |

| Industrie | Pièces d'emboutissage métallique |

| Tolérances | ±0,01 mm |

| Personnalisé | Disponible |

| Épaisseur | 0.1mm – 12mm |

| Certification | ISO 9001:2015, RoHS |

| Marque déposée | OEM |

| Colis de transport | Plastic Bag/Bubble Pack + Cartons + Wooden Case |

| Spécification | OEM |

| Origine | Chine |

Surface Options:

-

Électroplacage

A process where a thin layer of metal is deposited onto the surface of the clips through an electrochemical reaction, enhancing corrosion resistance and durability.

-

Spray Coating

A technique that applies a fine mist of coating material to the surface of the clips, providing a uniform finish while enhancing protection against wear and environmental factors.

-

Polissage

A mechanical finishing process that smooths the surface of the clips, improving aesthetics and providing a high-gloss, refined appearance.

-

Oxydation

A treatment method that creates a controlled layer of oxide on the metal surface, improving resistance to corrosion and enhancing overall longevity of the clips.

Our Advantages

-

Specialized Expertise in OEM Manufacturing

We specialize in producing a wide variety of OEM components, including metal stamped, machined, deep-drawn, and sheet metal-formed parts, with an array of surface finishes tailored to client specifications.

-

Strategic Location Advantage

Our facility in Dongguan, Guangdong Province, offers a strategic proximity to Shenzhen’s major ports, enabling us to provide faster, more cost-efficient shipping solutions while enhancing our service capabilities for international customers.

-

Advanced Machinery and Skilled Workforce

Equipped with state-of-the-art machinery for punching, welding, CNC machining, milling, and grinding, we ensure precision and reliability in every production stage. Our skilled workforce operates these advanced systems with the utmost care and attention to detail.

-

Dedicated Technical Expertise and Support

Our team consists of experienced technicians focused on continuous technical development, ensuring that we remain at the forefront of manufacturing innovation. Supported by a dedicated team of professional engineers and foreign trade specialists, we are committed to delivering exceptional support and service to our clients.

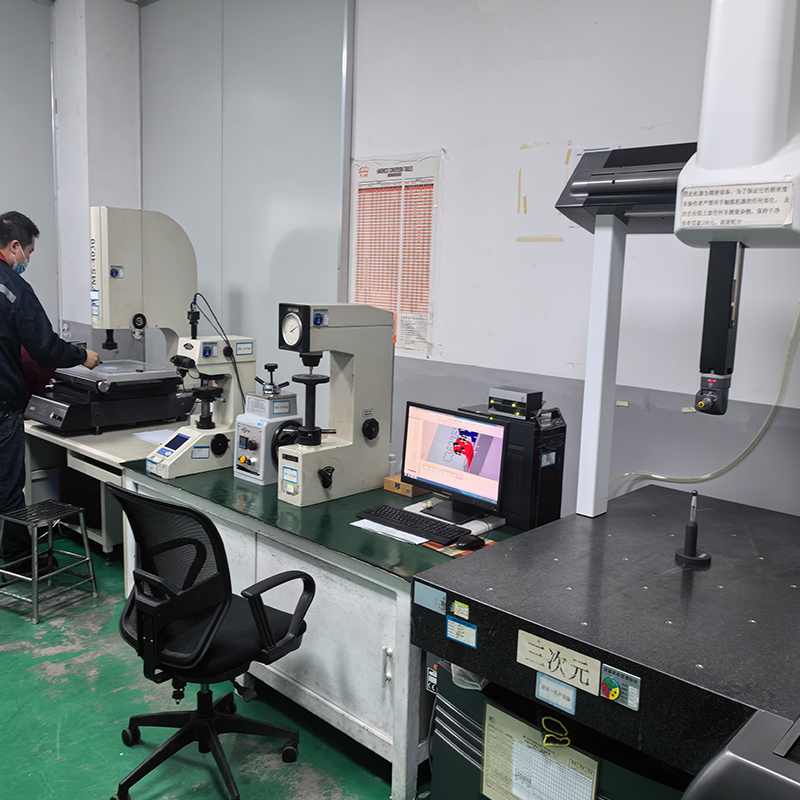

Spectacle de l'Usine :

Nous exploitons une gamme complète d'installations et d'équipements afin de garantir une production de la plus haute qualité. Nos installations sont équipées de 25 presses à emboutir allant de 25 tonnes à 300 tonnes, de machines de découpe par fil EDM de précision, d'équipements de rectification, d'outils de soudage et de polissage, ainsi que de systèmes de nettoyage par ultrasons.

En plus de nos capacités de fabrication, nous proposons une variété de procédés de revêtement métallique pour améliorer la durabilité, l'apparence et la fonctionnalité de nos produits d'emboutissage métallique. Ces procédés incluent l'électroplacage, le placage au zinc, le placage au nickel, le placage au chrome et l'anodisation. Nos installations de revêtement à la pointe de la technologie garantissent des finitions uniformes, une résistance à la corrosion et la conformité aux normes de l'industrie.

Cette combinaison de lignes de production professionnelles et automatisées, d'équipements mécaniques avancés, de mesures rigoureuses de contrôle qualité et de procédés de placage de haute qualité garantit que nous livrons des produits d'emboutissage métallique d'une qualité exceptionnelle.