Aperçu :

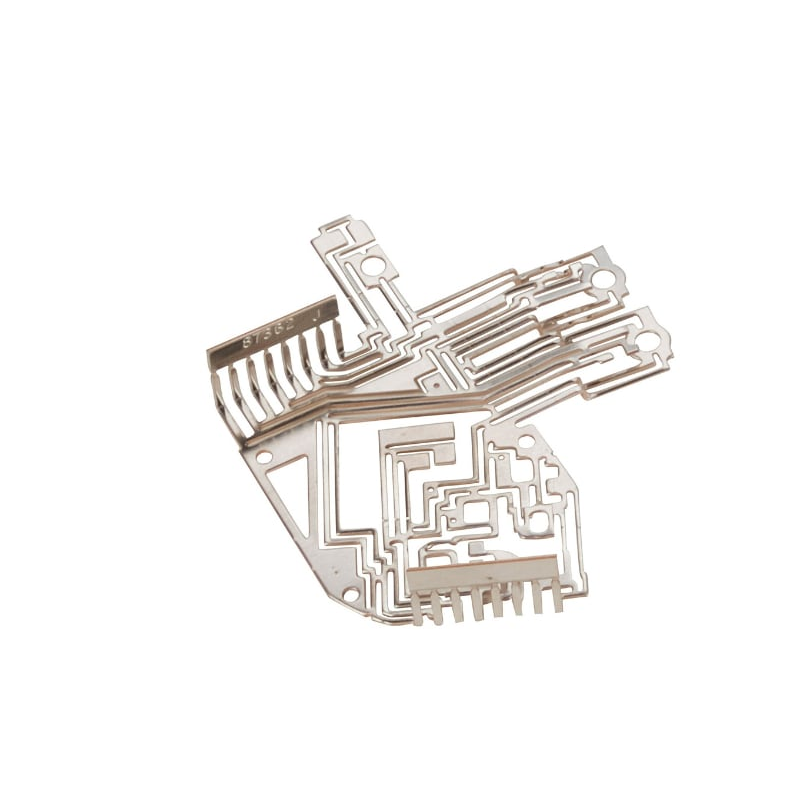

Nos cadres de connexion garantissent des connexions électriques sûres et fiables, jouant un rôle crucial dans la performance des semi-conducteurs. Dotés d'un placage en étain pour une résistance accrue à la corrosion et une meilleure soudabilité, ils sont parfaitement adaptés aux dispositifs hautes performances. Plantmetal est un fabricant et fournisseur leader de cadres de connexion de haute précision conçus pour les microprocesseurs, l'automobile et les applications électroniques. Avec une qualité et une précision inégalées, nos cadres de connexion sont conçus pour optimiser le fonctionnement des semi-conducteurs, répondant aux exigences strictes des technologies modernes. Faites confiance à notre entreprise pour vos besoins en cadres de connexion, là où innovation et fiabilité se conjuguent.

Détails :

| Attribut | Détails |

| Lieu d'origine | Xiamen, Chine |

| Nom de la marque | OEM |

| Matériau | Cuivre |

| Nom du produit | Cadre de connexion |

| Application | Médical, Industriel, Électronique |

| Service | Personnalisé OEM |

| Traitement de Surface | Disponible |

| Taille | Taille personnalisée |

| Logo | Gravé avec le logo de votre entreprise |

| Finition de surface | No burrs, marks; very clean |

| Épaisseur | 0,05 mm – 0,1 mm |

| Couleur | Couleur Personnalisée |

Processus de production :

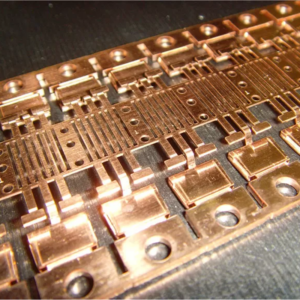

- Préparation des matériaux : Le cuivre ou les alliages de cuivre de haute qualité sont nettoyés afin de garantir une surface lisse pour l'estampage et le placage.

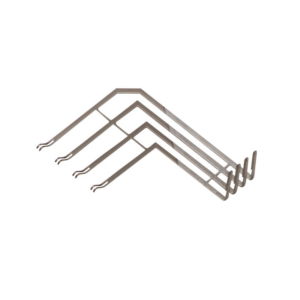

- Estampage de précision : Le matériau est estampé en motifs complexes avec des tolérances serrées grâce à des machines de pointe.

- Ébavurage et nettoyage : Les arêtes vives et les résidus d'estampage sont éliminés afin de garantir une surface impeccable.

- Étamage : Une fine couche d'étain est déposée par électrolyse afin d'assurer une résistance à la corrosion, d'améliorer la soudabilité et de garantir des connexions électriques fiables.

- Après traitement : Le rinçage, le séchage et l'application de revêtements anti-ternissement protègent la surface plaquée et préservent sa qualité.

- Contrôle Qualité : Chaque lot est inspecté pour vérifier la précision dimensionnelle et la fiabilité fonctionnelle.

- Conditionnement : Les cadres de connexion sont emballés de manière sécurisée pour une livraison en toute sécurité.

Options de traitement de surface :

- Passivation chimique : Un traitement de protection qui améliore la résistance à la corrosion et prolonge la durée de vie du composant en créant une couche superficielle stable et inerte.

- Dorure électrolytique : Un revêtement de surface de haute précision offrant une excellente conductivité, une résistance à la corrosion et à l'usure, idéal pour les applications hautes performances.

- Argenture électrolytique : Un revêtement durable offrant une conductivité électrique et une résistance à l'oxydation supérieures, idéal pour les composants électriques et électroniques.

- Nickelage électrolytique : Un revêtement polyvalent qui améliore la résistance mécanique, la résistance à l'usure et la protection contre la corrosion, tout en servant d'excellente base pour des dépôts ultérieurs.

Notre Usine :

Nos installations comprennent 25 presses à découper (de 25 à 300 tonnes), une machine d'électroérosion à fil de précision, des équipements de meulage, de soudage, de polissage et des systèmes de nettoyage par ultrasons. Nous proposons également des options avancées de traitement de surface telles que la galvanoplastie, la zinguerie, le nickelage, le chromage et l'anodisation pour améliorer la durabilité, la fonctionnalité et l'esthétique des pièces. Grâce à une automatisation professionnelle, des équipements de pointe et un contrôle qualité rigoureux, nous garantissons des produits d'estampage métalliques de haute qualité conformes aux normes de l'industrie.